Soft-touch modified material with low volatile organic compounds and low odor and preparation method thereof

A low-volatility, modified material technology, applied in the field of polymer materials, can solve problems such as deformation, insufficient rigidity, and small modulus, and achieve the effect of simple process, convenient operation, and increased absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

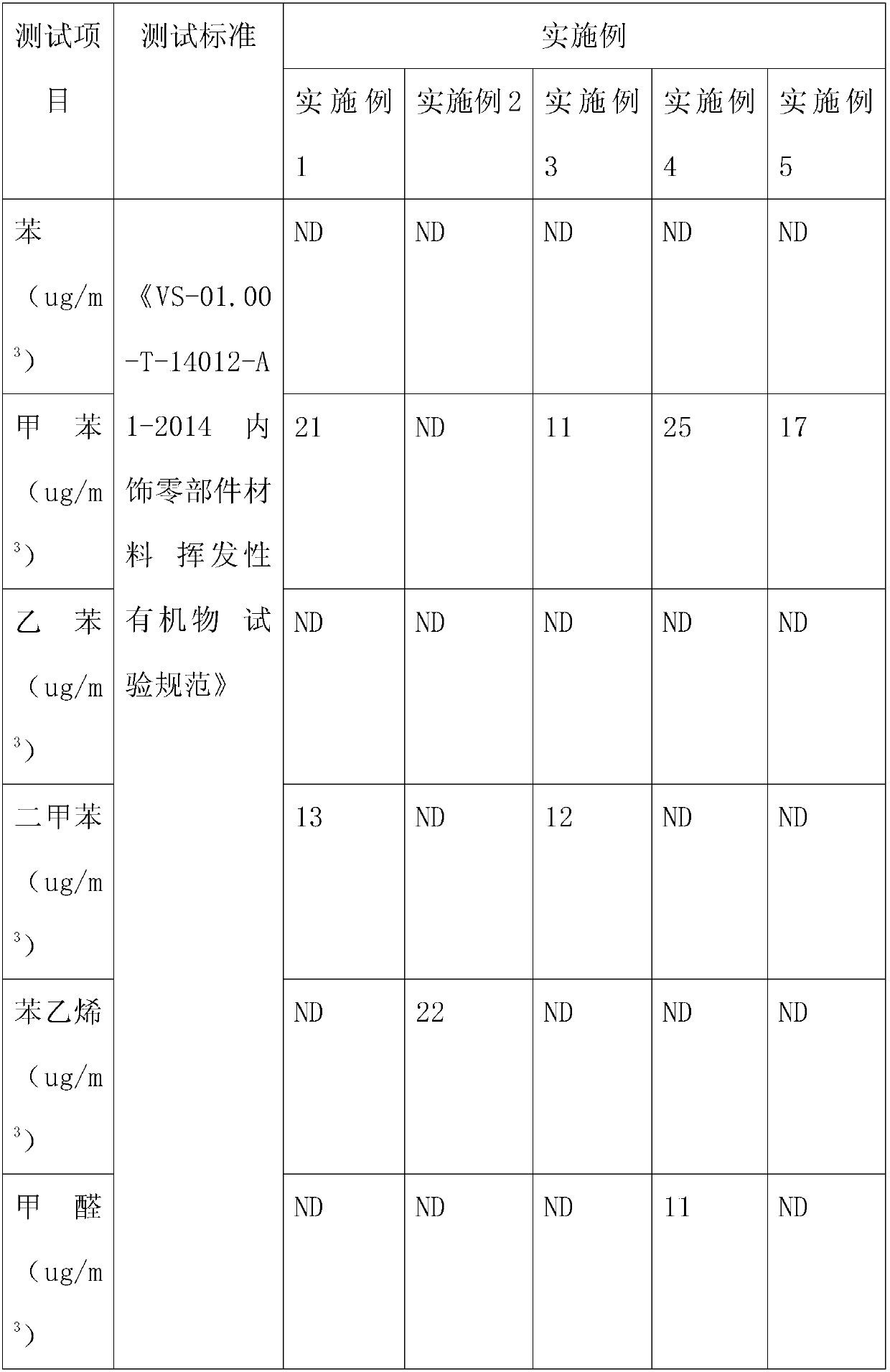

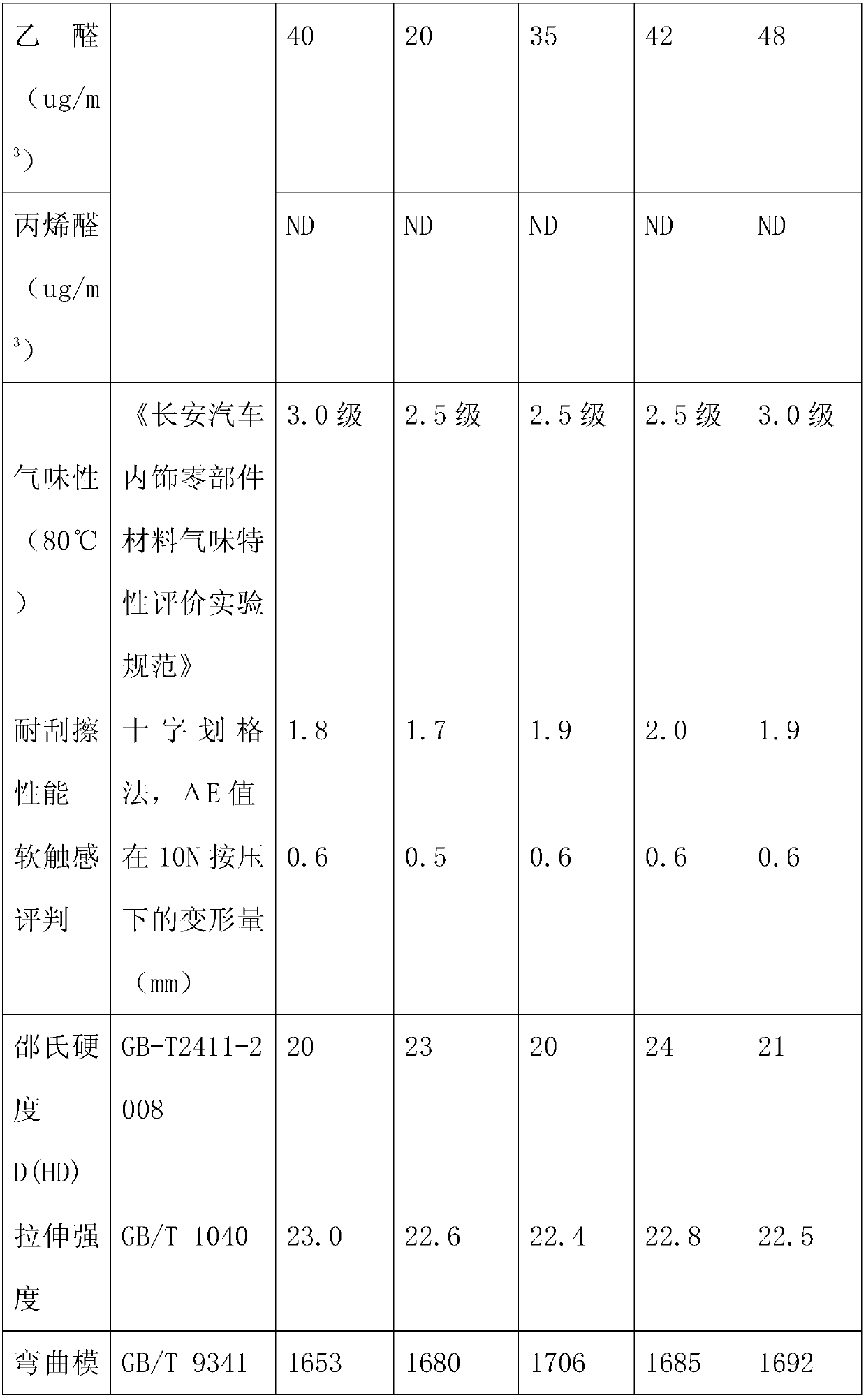

Examples

Embodiment 1

[0027] A method for preparing a low-volatile organic compound and low-odor soft-touch modified material, comprising the following steps:

[0028] (1) Weigh 20 parts of polypropylene PP-BX3920 (polypropylene material produced by SK Chemicals in South Korea, its melt index is 100g / 10min), 30 parts of glass fiber, 1 part of silicone HMB-0221, 15 parts of high crystallinity Homopolypropylene, 30 parts of ethylene-octene copolymer, 3 parts of maleic anhydride grafted polypropylene, 0.3 part of primary antioxidant 1010, 0.2 part of secondary antioxidant 168, 0.5 part of lubricant ethylene bisstearate amides;

[0029] (2) After the raw materials are mixed, they are stirred and mixed evenly in a stirring pot, and then added to a twin-screw extruder. The extrusion equipment of the twin-screw extruder is equipped with 3 vacuum pumps, and the processing temperature is 200-210 ° C for blending and extrusion. After cooling, it is cut into 2-3mm granules, and it is obtained by deodorizing ...

Embodiment 2

[0031] A method for preparing a low-volatile organic compound and low-odor soft-touch modified material, comprising the following steps:

[0032] (1) Weigh 40 parts of polypropylene PP-BX3920 (polypropylene material produced by SK Chemicals in South Korea, its melt index is 80g / 10min), 10 parts of glass fiber, 2 parts of silicone HMB-0221, 22 parts of high crystallinity Homopolypropylene, 20 parts of ethylene-octene copolymer, 5 parts of maleic anhydride grafted polypropylene, 0.3 parts of primary antioxidant 1010, 0.2 parts of secondary antioxidant 168, 0.5 parts of lubricant ethylene bis Stearamide.

[0033] (2) After the raw materials are mixed, they are stirred and mixed evenly in a stirring pot, and then added to a twin-screw extruder. The extrusion equipment of the twin-screw extruder is equipped with 2 vacuum pumps, and the processing temperature is 200-210 ° C for blending and extrusion. After cooling, it is cut into 2-3mm granules, and it is obtained by deodorizing t...

Embodiment 3

[0035] A method for preparing a low-volatile organic compound and low-odor soft-touch modified material, comprising the following steps:

[0036] (1) Weigh 30 parts of polypropylene PP-BX3920 (polypropylene material produced by SK Chemicals in South Korea, its melt index is 85g / 10min), 20 parts of glass fiber, 2 parts of silicone HMB-0221, 18 parts of high crystallinity Homopolypropylene, 25 parts of ethylene-octene copolymer, 4 parts of maleic anhydride grafted polypropylene, 0.3 parts of primary antioxidant 1010, 0.2 parts of secondary antioxidant 168, 0.5 parts of lubricant ethylene bis Stearamide.

[0037] (2) After the raw materials are mixed, they are stirred and mixed evenly in a stirring pot, and then added to a twin-screw extruder. The extrusion equipment of the twin-screw extruder is equipped with 3 vacuum pumps, and the processing temperature is 200-210 ° C for blending and extrusion. After cooling, it is cut into 2-3mm granules, and it is obtained by deodorizing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com