Production technology of black soybean vinegar

A black bean vinegar and black bean technology, which is applied in the field of food processing, can solve the problem that black beans cannot be fully released, and achieve the effects of improving the process yield, improving the utilization rate and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

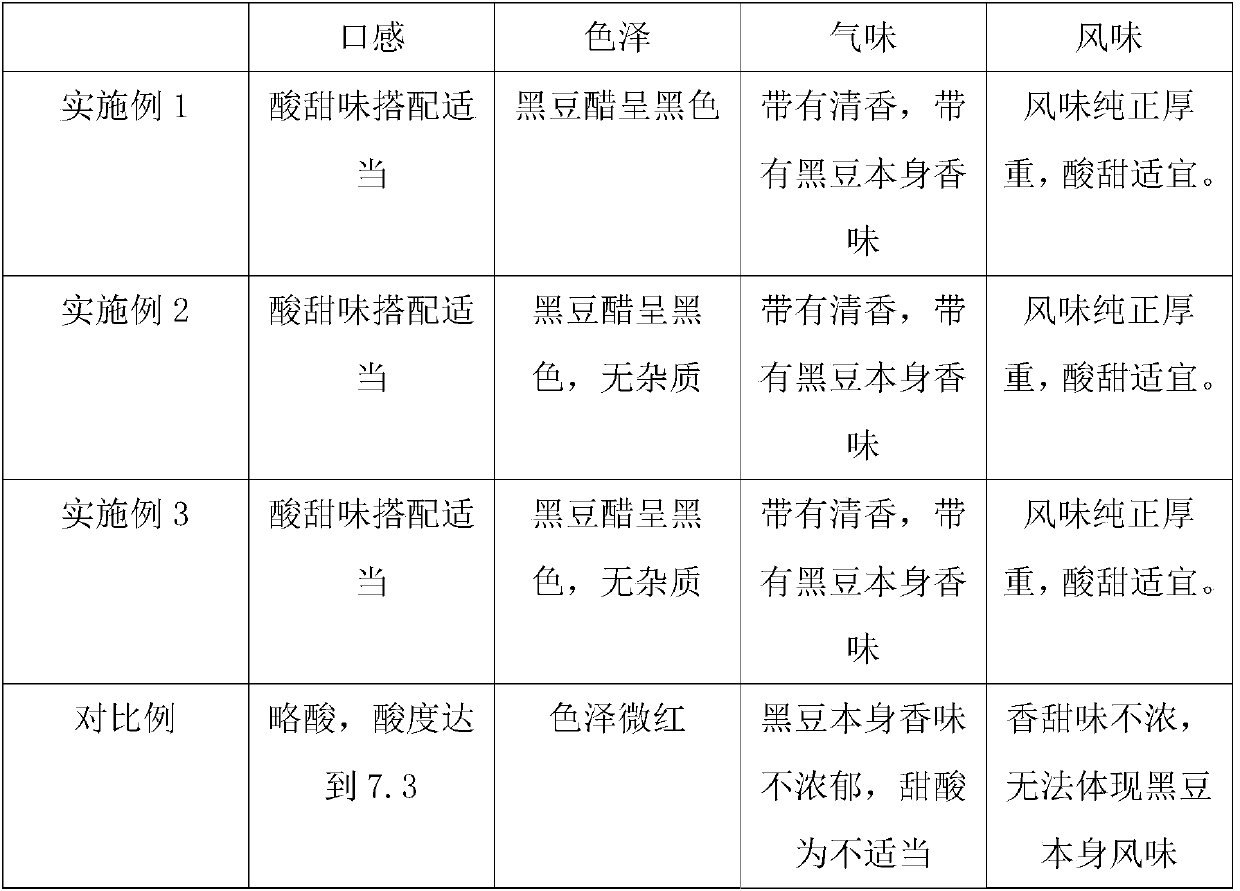

Examples

Embodiment 1

[0036] A kind of black soybean vinegar processing method, described processing method follows the steps:

[0037] Step 1, weighing black soybean mixture, wheat, sorghum rice, peas, pulverized bran, rice bran and Daqu according to the proportion;

[0038] Step 2, put black beans, wheat, sorghum rice, peas, pulverized bran and bran in a steamer and steam for 120 minutes;

[0039] Step 3, put the steamed raw materials into the fermentation tank, spread out to cool, pour in Daqu after cooling, stir, and then ferment at constant temperature for 15 days;

[0040] Step 4, putting the fermented raw materials into the smoking and roasting pool for 15 days;

[0041] Step 5, spraying vinegar on the smoked and roasted raw materials, and then storing them in tanks or bottling them through pipelines.

[0042] The black bean mixture comprises black bean kernels and black bean skins whose content is one-third of the total mass of the black bean mixture, and black beans whose content is two-...

Embodiment 2

[0049] A kind of black soybean vinegar processing method, described processing method follows the steps:

[0050] Step 1, weighing black soybean mixture, wheat, sorghum rice, peas, pulverized bran, rice bran and Daqu according to the proportion;

[0051] Step 2, put black beans, wheat, sorghum rice, peas, pulverized bran and bran in a steamer and steam for 120 minutes;

[0052] Step 3, put the steamed raw materials into the fermentation tank, spread out to cool, pour in Daqu after cooling, stir, and then ferment at constant temperature for 15 days;

[0053] Step 4, putting the fermented raw materials into the smoking and roasting pool for 15 days;

[0054] Step 5, spraying vinegar on the smoked and roasted raw materials, and then storing them in tanks or bottling them through pipelines.

[0055] The black bean mixture comprises black bean kernels and black bean skins whose content is one-third of the total mass of the black bean mixture, and black beans whose content is two-...

Embodiment 3

[0062] A kind of black soybean vinegar processing method, described processing method follows the steps:

[0063] Step 1, weighing black soybean mixture, wheat, sorghum rice, peas, pulverized bran, rice bran and Daqu according to the proportion;

[0064] Step 2, put black beans, wheat, sorghum rice, peas, pulverized bran and bran in a steamer and steam for 120 minutes;

[0065] Step 3, put the steamed raw materials into the fermentation tank, spread out to cool, pour in Daqu after cooling, stir, and then ferment at constant temperature for 15 days;

[0066] Step 4, putting the fermented raw materials into the smoking and roasting pool for 15 days;

[0067] Step 5, spraying vinegar on the smoked and roasted raw materials, and then storing them in tanks or bottling them through pipelines.

[0068] The black bean mixture comprises black bean kernels and black bean skins whose content is one-third of the total mass of the black bean mixture, and black beans whose content is two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com