Preparation method forlarge-grain and low-hardness sputtering titanium ring

A low-hardness, large-grain technology, used in sputtering, ion implantation, coating, etc., can solve the problems of high hardness and small titanium ring grains, and achieve low hardness, low deformation resistance, and reduced The effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

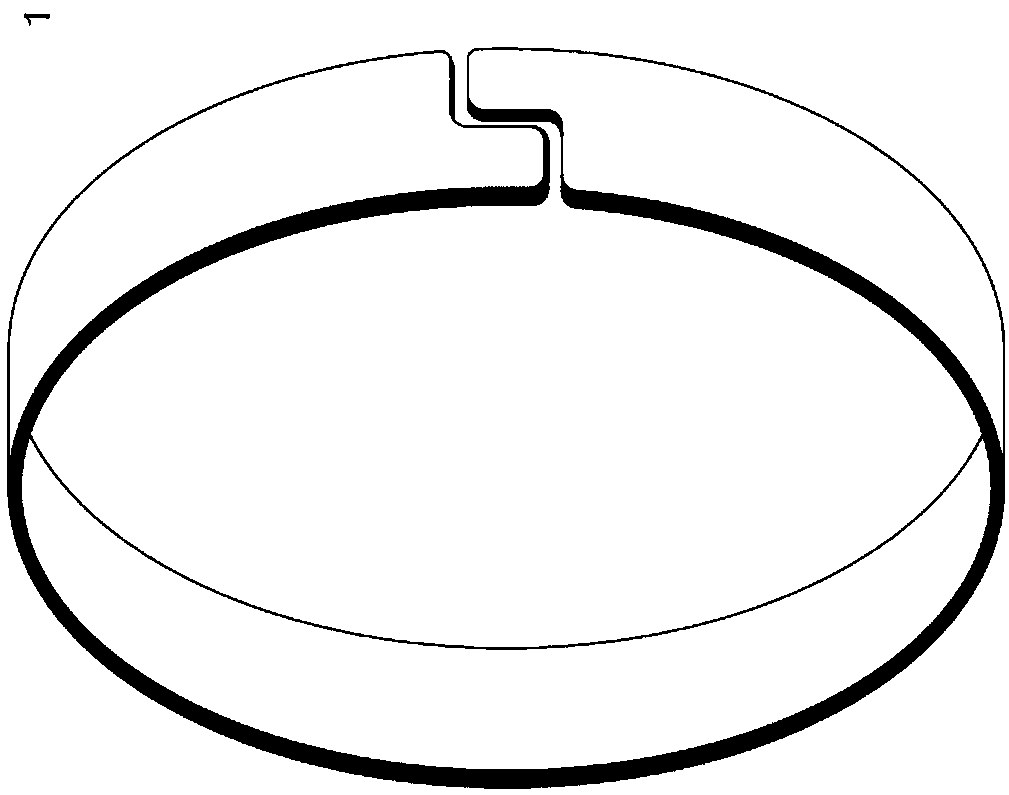

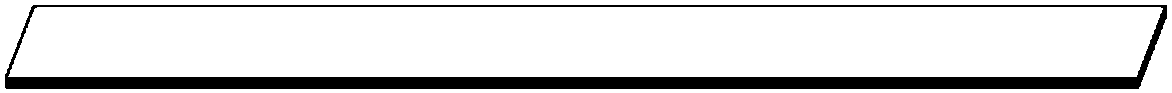

[0029] Take 10kg of high-purity titanium ingot, hold it at 580°C for 1.5h for the first heat treatment, and then upset it into 170mm×70mm in multiple steps while it is hot, roll it unidirectionally along the length direction to a thickness of 7.5mm, cut off the irregular part of the edge, and Hold at 650°C for 3 hours for the second heat treatment and then level off as attached figure 1 As shown, the waterjet cutting into a 1242mm×80mm port is a positive "S"-shaped slat blank as attached figure 2 As shown, after removing the surface dirt, it is rolled into a ring, and the vacuum degree is 8.5×10 -3 Pa vacuum annealing furnace at 820 ℃ for 3 hours for the third heat treatment, cleaning the surface to obtain titanium ring as attached image 3 shown.

[0030] It should be noted that among the present invention, each flattened slab (as attached figure 1 ) can be cut by waterjet into two slab blanks with positive S-shaped ports (as attached figure 2 ).

[0031] By changing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com