Fiber composite pile for marine environment and preparation method of fiber composite pile

A technology of fiber composite and marine environment, applied in the field of pile foundation structure, can solve the problems affecting the mechanical properties of the structure, achieve good corrosion resistance effect, reduce load, and prevent freeze-thaw cycle damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation of square fiber composite pile, comprises the following steps:

[0042] Step 1: Make a fiber composite pile template with a pile body length of 19.3m, a pile tip length of 0.7m, and a pile body cross-section of a square with a side length of 0.45m;

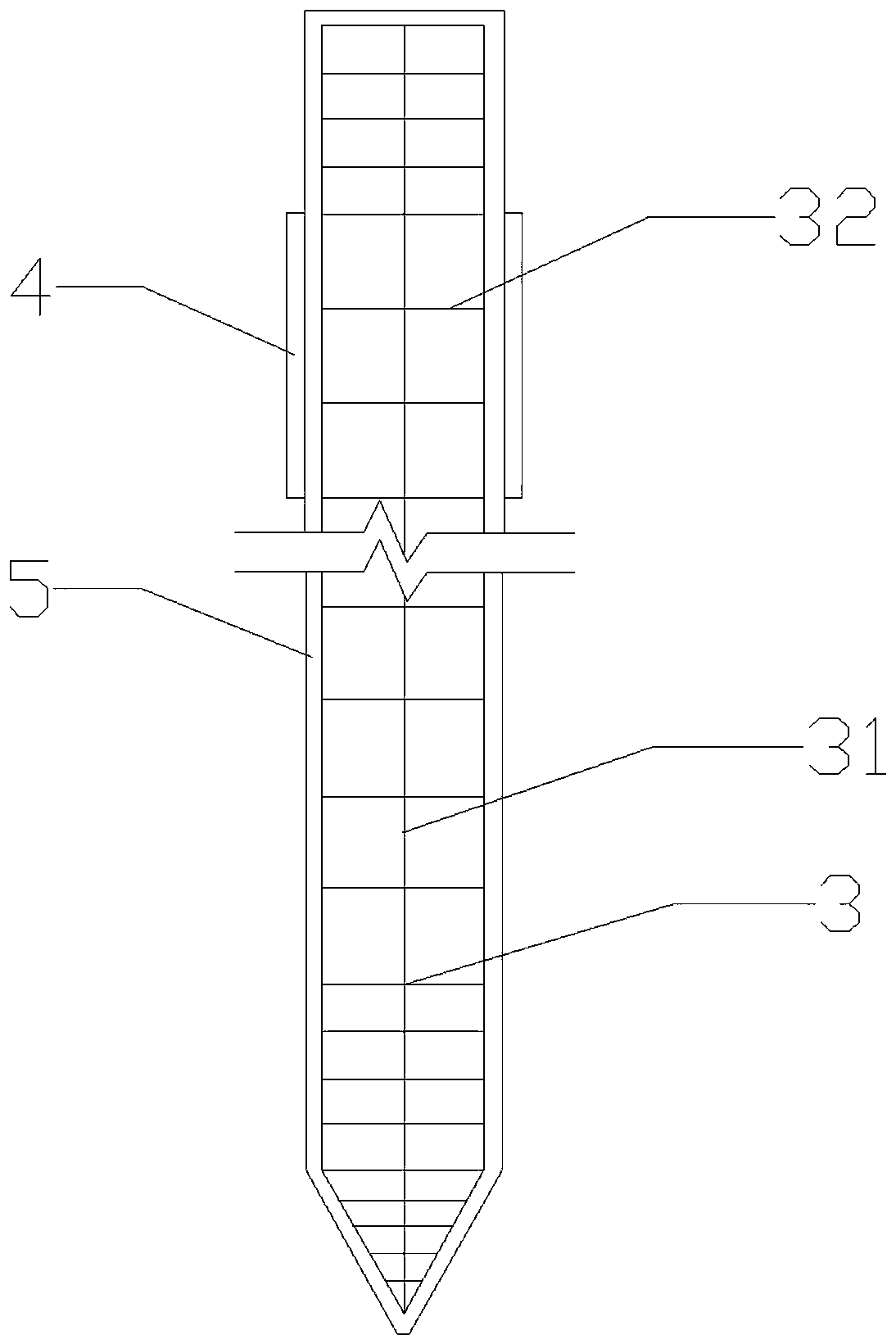

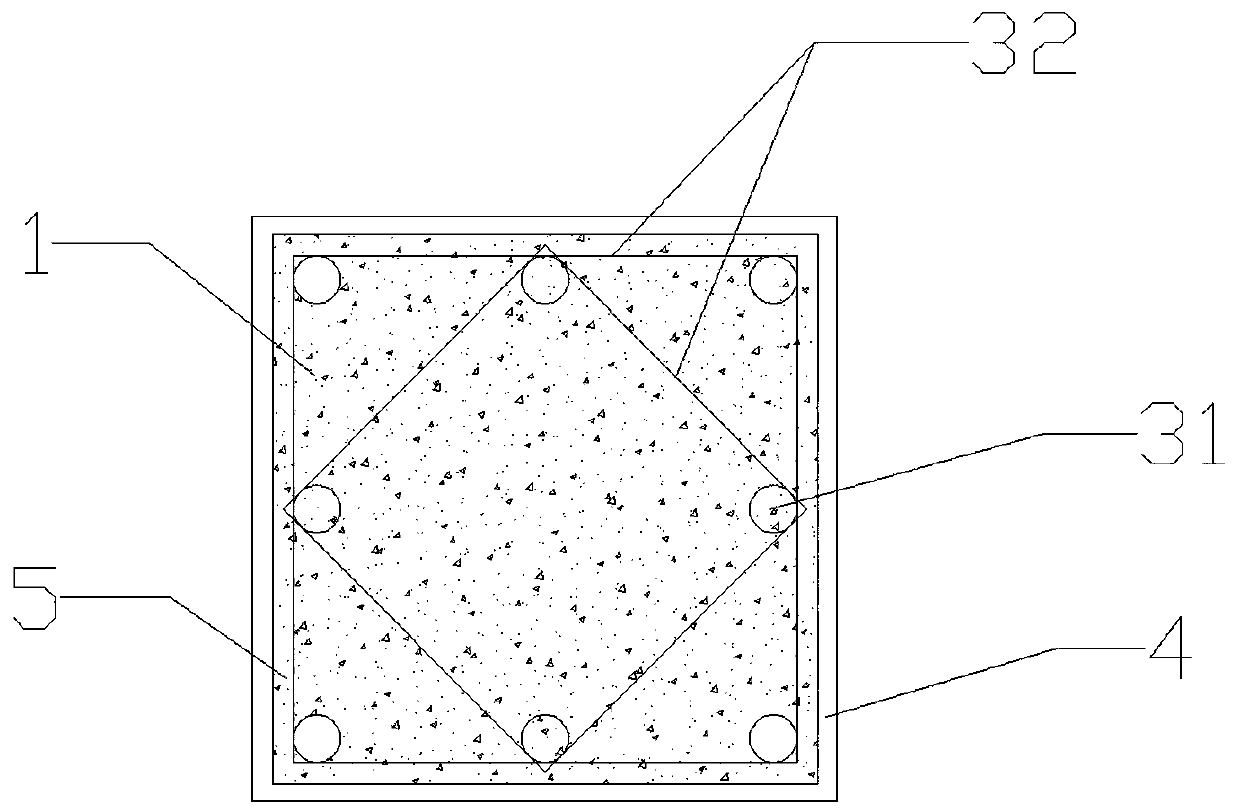

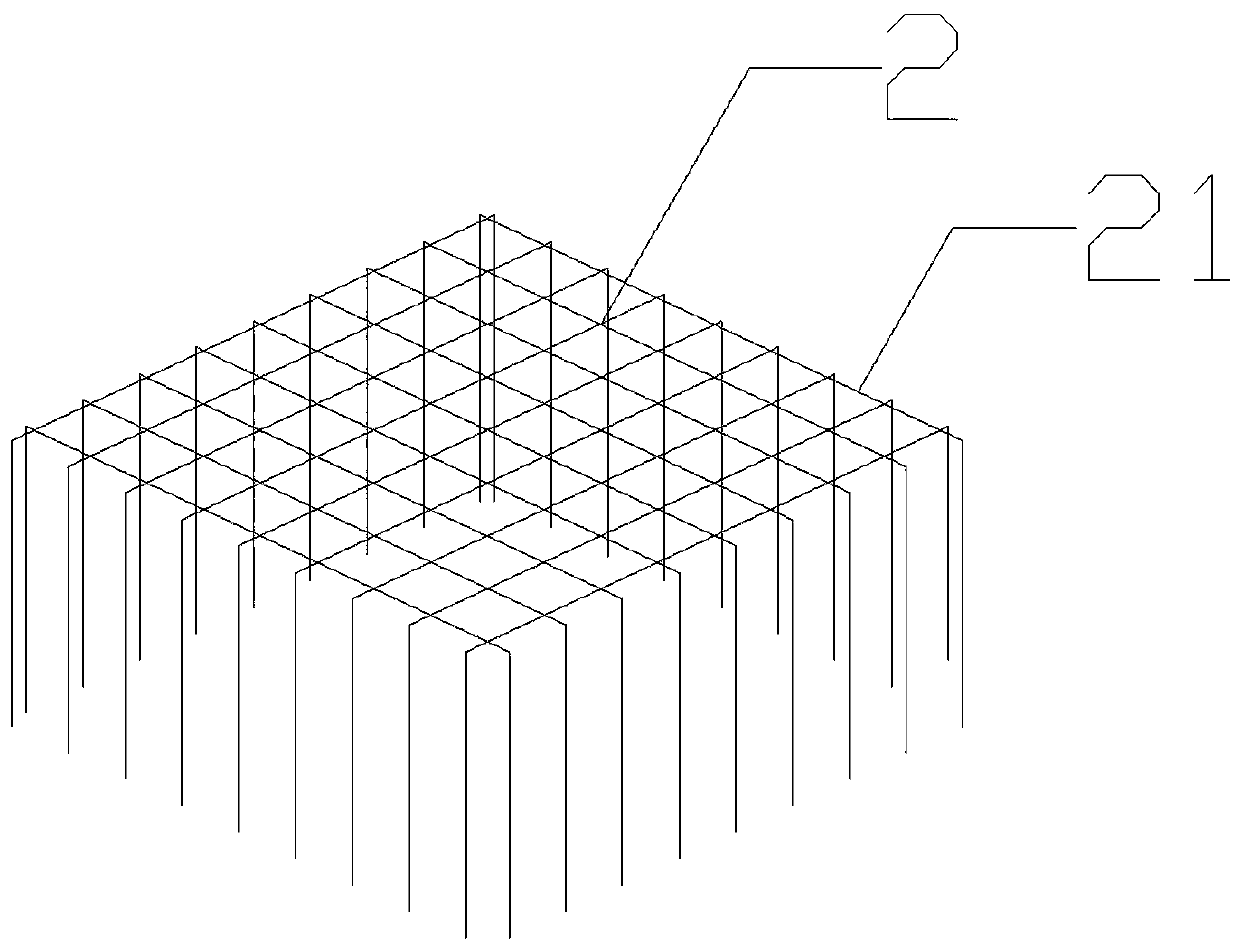

[0043] Step 2: First make the FRP reinforcement cage: use 8 FRP reinforcements with a diameter of 20mm as the reinforcements of the pile body, and tie them on the 8 FRP reinforcements and the 4 FRP reinforcements in the middle of the composite pile facade in turn FRP stirrups with a diameter of 6-10mm, such as figure 2 As shown, the FRP reinforcement cage of the pile body is made; FRP stirrups with a diameter of 6 mm are bound on 8 FRP reinforcements with a diameter of 16 mm to make a FRP reinforcement cage at the pile tip; Reinforcement bars are vertically intersected at the top of the pile to form an FRP reinforcement cage at the top of the pile, such as Figure 3-4 As shown, the distance between ...

Embodiment 2

[0053] A kind of preparation of circular fiber composite post, comprises the following steps:

[0054] Step 1: Make a circular fiber composite pile template with a pile body length of 19.3m, a pile tip length of 0.7m, and a pile body cross-section with a diameter of 0.6m;

[0055] Step 2: First make the FRP cage: as Figure 5 As shown, FRP stirrups with a diameter of 6 to 10 mm are bound on eight FRP tendons with a diameter of 22 mm to make a pile body FRP cage; eight FRP tendons with a diameter of 16 mm are bound with a diameter of 6 mm FRP stirrups made of pile tip FRP cages;

[0056] The diameter of the FRP stirrup bound on the 560mm-long part of the upper end of the FRP stress tendon of the FRP cage of the pile body is 10mm, and the spacing is 70mm. Then the diameter of the FRP stirrup bound on the 16800mm long FRP stress bar is 8mm, and the spacing is 200mm; The diameter of the FRP stirrup is 6mm, and the spacing is 50mm;

[0057] Then set a 50mm concrete protective l...

Embodiment 3

[0065] A kind of preparation of annular fiber composite pile, comprises the following steps:

[0066] Step 1: Make a fiber composite pile template with a pile length of 19.3m, a pile tip length of 0.7m, and a ring-shaped cross-section of the pile body, in which the diameter of the outer ring is 0.6m and the diameter of the inner ring is 0.3m;

[0067] Step 2: First make the FRP cage: as Figure 6 As shown, FRP stirrups with a diameter of 6-10 mm are bound on eight FRP tendons with a diameter of 25 mm to make a FRP cage for the pile body; FRP stirrups made of pile tip FRP cages;

[0068] The diameter of the FRP stirrup bound on the 560mm-long part of the upper end of the FRP stress tendon of the FRP cage of the pile body is 10mm, and the spacing is 70mm. Then the diameter of the FRP stirrup bound on the 16800mm long FRP stress bar is 8mm, and the spacing is 200mm; The diameter of the FRP stirrup is 6mm, and the spacing is 50mm;

[0069] Then set a 50mm concrete protective l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com