Three-level high-voltage and large-power water-cooling frequency converter system

A frequency converter and high-power technology, applied in the field of electrical control structural components, to achieve the effects of installation and maintenance, suppression of bus overvoltage, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

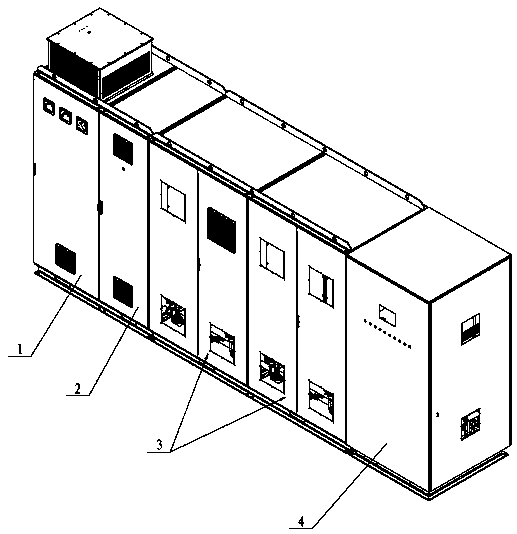

[0027] Embodiment 1: see figure 1 , a three-level high-voltage high-power water-cooled inverter system, including: a full-digital control cabinet 2, an inverter cabinet 3 based on a double-arm power unit, and a water circulation cooling system cabinet 4; the full-digital control cabinet 2, based on a dual The inverter cabinet 3 of the bridge arm power unit and the water circulation cooling system cabinet 4 are assembled and combined from left to right to form a complete set of high-voltage and high-power water-cooled inverter system. The entire inverter system adopts a double bridge arm parallel structure. The overall structure scheme It can be more flexibly adapted to applications requiring various output powers. According to actual needs, an excitation winding cabinet 1 can also be added. The excitation winding cabinet 1 is arranged on one side of the all-digital regulating cabinet 2 . In terms of space volume utilization, the design is more reasonable and compact, enabling ...

Embodiment 2

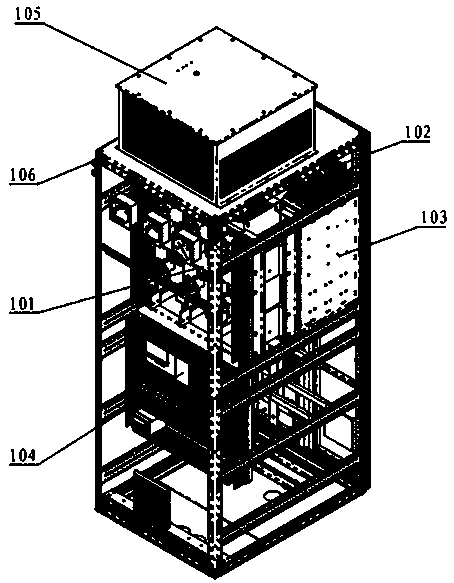

[0028] Example 2: see figure 1 , as an improvement of the present invention, the full digital control cabinet 2 includes a core control module, an auxiliary power supply system, a man-machine dialogue system and a cabinet, and the core control module adopts a vector controller with a DSP+FPGA structure , with a 32-bit digital model processor as the core; realize speed closed-loop control, unit power factor control, frequency conversion vector control, current closed-loop control, fault diagnosis and other functions. Installed at the front of the full digital control cabinet; the auxiliary power supply system is used to provide stable operating power for the auxiliary control of the entire system, and is installed at the rear of the cabinet; the man-machine dialogue system adopts a touch screen man-machine dialogue operation interface, installed In the middle of the front of the cabinet.

Embodiment 3

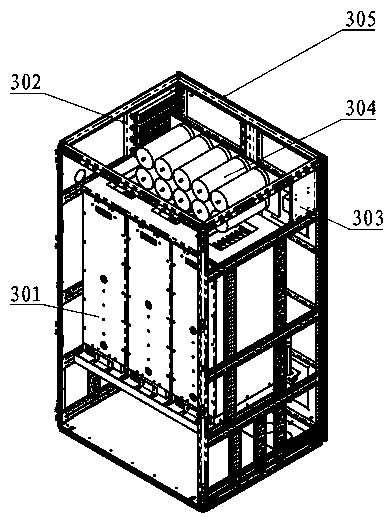

[0029] Embodiment 3: see figure 1 , image 3 , the inverter cabinet 3 based on the double-bridge arm power unit includes a cabinet body 305 and three sets of double-bridge arm power unit modules 301, discharge modules 302, sensor modules 303, and spare expansion support capacitors installed in the cabinet Module 304, the double-arm power unit module 301 is installed in the front of the cabinet; the discharge module 302 is fixed on the left side of the upper part of the cabinet by bolts, and the sensor module 303 is fixed on the upper part of the cabinet by bolts On the right side, the spare extended support capacitor module 204 is arranged above the dual-arm power unit module 301 . The inverter based on the double-bridge arm power unit adopts AFE active front-end technology, and the advanced back-to-back three-level AC-DC-AC frequency conversion method ensures stable four-quadrant operation on the power side of the inverter. Among them, the power unit module adopts the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com