Alfalfa silage for dairy cows and preparation method thereof

A technology of alfalfa and silage, applied in animal feed, animal feed, applications, etc., can solve problems such as difficulty in satisfying lactic acid bacteria, low nutritional value of silage, and difficulty in forming a low pH state, so as to improve silage quality and palatability sex, the effect of lowering the pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

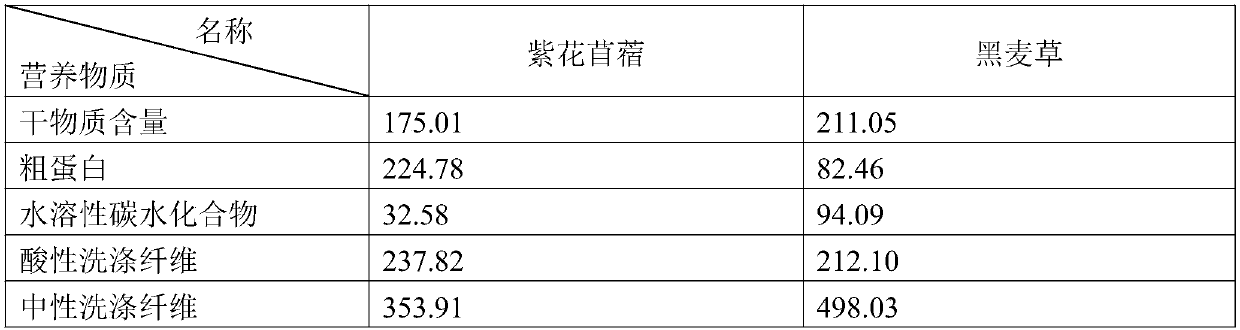

Embodiment 1

[0025] A kind of alfalfa silage for dairy cows, which comprises the following components and raw materials by weight: 20-40 parts of alfalfa, 60-200 parts of ryegrass, 5-10 parts of sweet sorghum straw, 5-20 parts of hawthorn, and astragalus polysaccharide 2-4 parts, lactic acid bacteria preparation 4.0mg / kg-7.0mg / kg.

[0026] Optionally, the alfalfa silage for dairy cows also includes the following raw materials in parts by weight: 7-10 parts of ginseng stems and leaves, and 1-2 parts of licorice extract.

[0027] The alfalfa silage for dairy cows provided by the application prevents rumen inflation caused by frequent consumption of dairy cows by adding hawthorn powder, and improves the palatability of the alfalfa silage feed by adding sweet sorghum stalks and astragalus polysaccharides. In addition, the alfalfa silage for dairy cows provided by the application has a simple preparation process, reduces the pH value of the silage, increases the content of lactic acid and water...

Embodiment 2

[0029] A kind of alfalfa silage for dairy cows, comprising the following components and raw materials by weight: 30 parts of alfalfa, 70 parts of ryegrass, 8 parts of sweet sorghum straw, 10 parts of hawthorn, 3 parts of astragalus polysaccharide, and 6.0 mg / kg of lactic acid bacteria preparation .

[0030] Optionally, the alfalfa silage for cows also includes 8 parts of ginseng stems and leaves and 1 part of licorice extract.

Embodiment 3

[0032] A kind of alfalfa silage for dairy cows, comprising the following components and raw materials by weight: 40 parts of alfalfa, 200 parts of ryegrass, 6 parts of sweet sorghum straw, 8 parts of hawthorn, 2 parts of astragalus polysaccharide, and 5.0 mg / kg of lactic acid bacteria preparation .

[0033] Optionally, the alfalfa silage for dairy cows also includes 7 parts of ginseng stems and leaves and 2 parts of licorice extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com