Rock wool roll felt production equipment and production method thereof

A production equipment and rolling felt technology, applied in the field of insulation material preparation, can solve the problem that the thimble cannot penetrate the dense rock wool board, and achieve the effect of simple structure, precise piercing, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

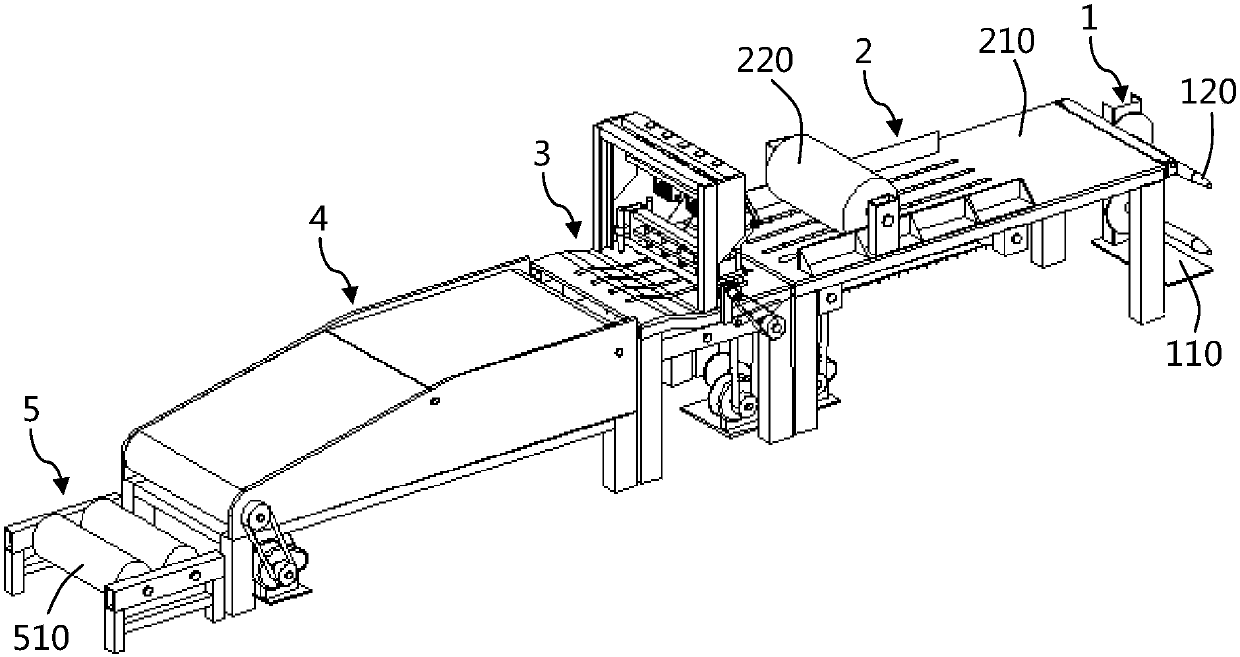

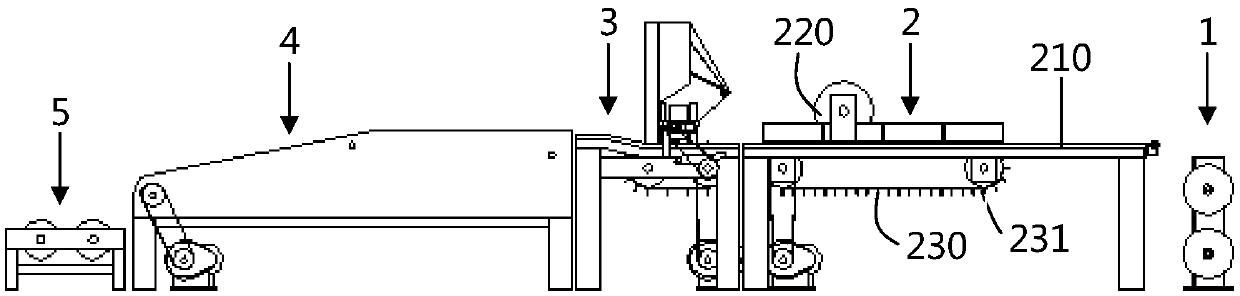

[0046] Such as Figure 1 to Figure 5 As shown, the rock wool roll felt production equipment in this embodiment includes a sewing mechanism 3 , a wire mesh conveying component 1 , a rolling mechanism 2 , a transmission belt 4 and a rock wool roll felt curling mechanism 5 .

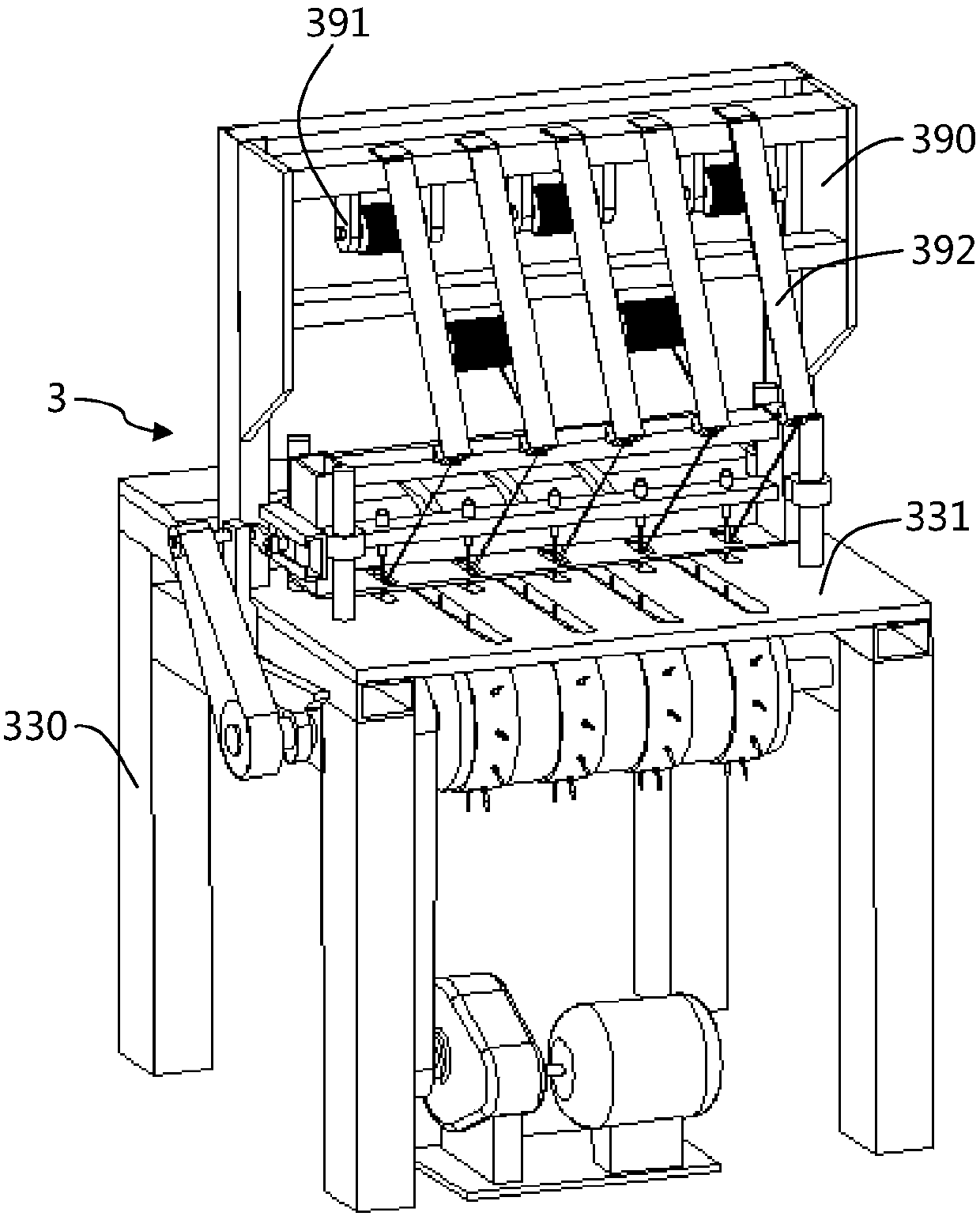

[0047] combine image 3 , Figure 4 , Figure 5 , the sewing mechanism 3 comprises a frame 330, a driving motor, a first belt 350, a transmission shaft 360, a second belt 370, a threading part 380, a thread feeding part 390, a thimble power part 310 and a thimble part 320, and the thimble power part 310 includes a guide Rod 311, power curved rod 312, slider 313 and base 314, power curved rod 312 is rotationally connected with slider 313; Placed in the guide groove 315, the base 314 is fixedly connected with the thimble part 320, the power crank 312 rotates to drive the slider 313 to move left and right, and at the same time drives the base 314 to move up and down, thereby realizing the up and down moveme...

Embodiment 2

[0055] The production method of the rock wool roll felt production equipment of the present embodiment comprises the following specific steps:

[0056] Step S101. Use the waste heat of the cupola to preheat the rock wool board. First, soak the rock wool board in an alkaline solution for 5-10 minutes, then drain the rock wool board and transport it to a drying room. The temperature changes from room temperature to Raise to 40°C, spray alkaline solution on the surface, and keep warm for 10 minutes; raise the temperature to 70°C, spray alkaline solution on the surface, keep warm for 10 minutes; then raise the temperature to 100°C, keep warm for 10 minutes; the alkaline solution used is bicarbonate sodium solution;

[0057] Step S102, set the steel wire mesh on the threading shaft 120, spread the head of the steel wire mesh on the conveying platform 210, and then place the pretreated rock wool board on the steel wire mesh while it is hot;

[0058] Step S103, turn on the motor of ...

Embodiment 3

[0061] The production method of the rock wool roll felt production equipment of the present embodiment comprises the following specific steps:

[0062] Step S101. Use the waste heat of the cupola to preheat the rock wool board. First, soak the rock wool board in an alkaline solution for 5-10 minutes, then drain the rock wool board and transport it to a drying room. The temperature changes from room temperature to Raise to 45°C, spray alkaline solution on the surface, and keep warm for 6 minutes; when the temperature rises to 74°C, spray alkaline solution on the surface, keep warm for 5 minutes; then raise the temperature to 110°C, keep warm for 10 minutes; the alkaline solution used is sodium carbonate solution;

[0063] Step S102, set the steel wire mesh on the threading shaft 120, spread the head of the steel wire mesh on the conveying platform 210, and then place the pretreated rock wool board on the steel wire mesh while it is hot;

[0064] Step S103, turn on the motor of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com