Plant fiber reinforced composite material based on methacrylate crosslinked soybean oil-based resin and preparation method thereof

A technology of soybean oil-based resin and methacrylate, applied in the direction of coating, etc., can solve the problems of poor heat resistance, high viscosity, environmental pollution, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

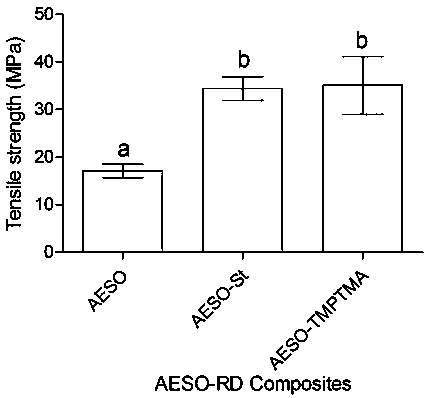

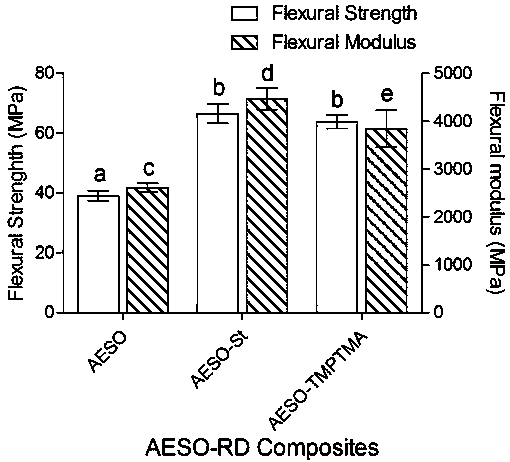

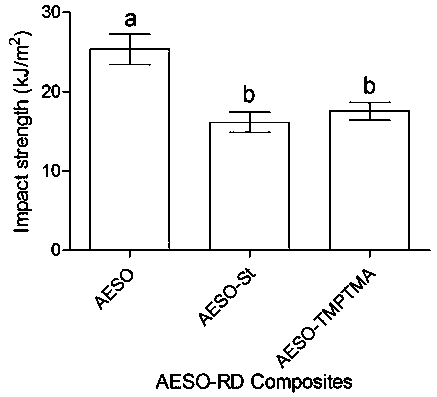

[0022] Vegetable Fiber / Methacrylate Soybean Oil-Based Resin Composites:

[0023] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (70g) and cross-linking agent (30g) are placed in a round bottom flask, and after stirring with a magnetic stirrer at room temperature for 20min, the soybean oil-based resin mixture is obtained; The soybean oil derivative is AESO; the cross-linking agent is TMPTMA; the initiator is TBPB.

[0024] Composite material preparation method: Weigh 76.4g of soybean oil-based resin mixture and 1.6g of TBPB, mix and stir for 1min with a glass rod. Take the dried plant fibers out of the oven, wrap them in plastic airtight bags, and when they are cooled to room temperature, stack 5-9 pieces of fiber mats (76.4g) in the orthogonal direction to form a fiber slab. Soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, then moved to a steel mold and preheated for 5 minutes at 70°C and a ...

Embodiment 2

[0037] Vegetable Fiber / Methacrylate Soybean Oil-Based Resin Composites:

[0038] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (60g) and cross-linking agent (40g) are placed in a round bottom flask, and after stirring with a magnetic stirrer at room temperature for 30min, the soybean oil-based resin mixture is obtained; The soybean oil derivative is AESO; the cross-linking agent is TMPTMA; the initiator is TBPB.

[0039] Composite material preparation method: Weigh 80g of soybean oil-based resin mixture and 2.5g of TBPB, mix and stir for 1min with a glass rod. Take the dried plant fiber out of the oven, wrap it in a plastic airtight bag, and when it cools down to room temperature, stack 5-9 pieces of fiber mats (90g) in the orthogonal direction to form a fiber slab. Soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, then moved to a steel mold and preheated at 70°C and 7MPa pressure for 4 minu...

Embodiment 3

[0041] Vegetable Fiber / Methacrylate Soybean Oil-Based Resin Composites:

[0042] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (80g) and cross-linking agent (20g) are placed in a round bottom flask, and after stirring with a magnetic stirrer at room temperature for 30min, the soybean oil-based resin mixture is obtained; The soybean oil derivative is AESO; the cross-linking agent is TMPTMA; the initiator is TBPB.

[0043] Composite material preparation method: Weigh 100g of soybean oil-based resin mixture and 3g of TBPB, mix and stir for 1min with a glass rod. Take the dried plant fiber out of the oven, wrap it in a plastic sealed bag, and when it cools down to room temperature, stack and arrange 5-9 pieces of fiber mats (80g) in the orthogonal direction to form a fiber slab. Soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, then moved to a steel mold and preheated for 5 minutes at 70°C and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com