Anti-static bicomponent formulation for unsaturated polyester resins and epoxy vinyl ester resins

An epoxy vinyl ester, unsaturated technology, applied in conductive coatings, chemical instruments and methods, and other chemical processes, can solve the problems of changing the final properties of products, loss of mechanical properties, and limiting the possibility of coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

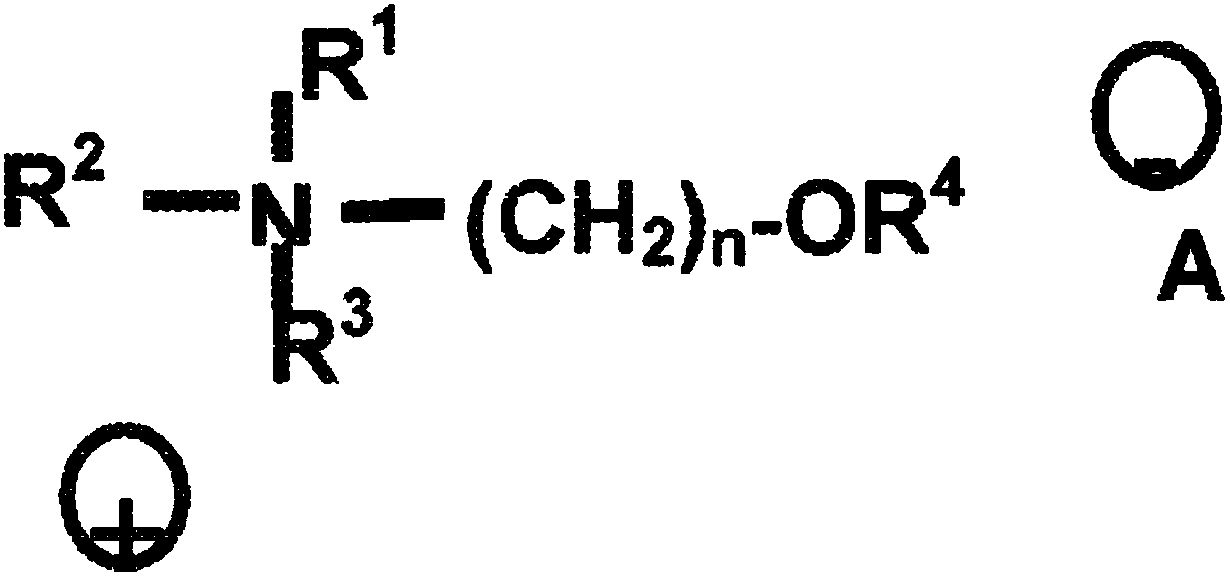

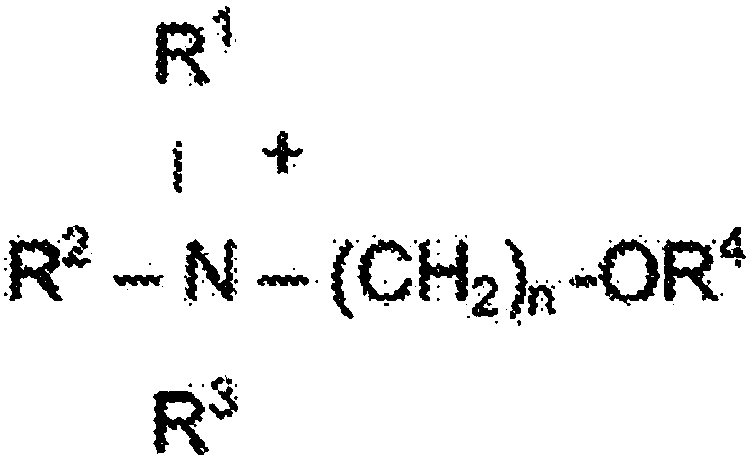

[0081] Salt prepared by encapsulation with sodium aluminosilicate precipitation (95%) (R 4 )N,N,N-trialkyl-alkyl-alcohol-ammonium, where R 1 , R 2 , R 3 is CH 3 , n=2 and OR 4 is OH and the anion is chloride (choline chloride) (5%).

[0082] Use 950 g sodium aluminosilicate, preferably it should have composition 10-14.5 (SiO 2 ), 0.5-1.5 (Al 2 o 3 ), 0.5-2 (Na 2 O), and a surface BET of 50 to 90m 2 / g, for this example we use a BET of 60m obtained by precipitation 2 / g of 14.5 (SiO 2 ) Al 2 o 3 1.4 (Na 2 O) fine powder. Add 50 g of salt (choline chloride) powder. Encapsulation was performed by mixing in a high speed rotary mixer at 2500 rpm for 10 minutes.

Embodiment 2

[0084] Preparation as described in Example 1, wherein the ratio is 10%-90%.

[0085] The preparation starts with a BET of 60m obtained from precipitation 2 / g of 900g sodium aluminosilicate 14.5 (SiO 2 ) Al 2 o 3 1.4 (Na 2 O) fine powder. Add 100 g of choline chloride powder. Encapsulation was performed by mixing in a high speed rotary mixer at 2500 rpm for 10 minutes.

Embodiment 3

[0087] Preparation as described in Example 1, wherein the ratio is 15%-85%.

[0088] The preparation starts with a BET of 60m obtained from precipitation 2 / g of 850g sodium aluminosilicate 14.5 (SiO 2 ) Al 2 o 3 1.4 (Na 2 O) fine powder. Add 150 g of choline chloride powder. Encapsulation was performed by mixing in a high speed rotary mixer at 2500 rpm for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com