A kind of screening method of metal powder

A technology of metal powder and metal powder, which is applied in the field of metal powder screening to achieve the effects of low equipment cost, avoiding pollution, and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 sieves the titanium alloy powder of 15~45 μm

[0053] (1) The metal powder raw material of 0-250 μm is prepared by an atomization method.

[0054] (2) The fine screen is 15μm, the coarse screen is 45μm, and the screen area is 0.2m 2 .

[0055] (3) Fill the screening system with high-purity Ar at a rate of 9 L / min, which corresponds to the outlet pressure of the pressure reducing valve at 0.5 MPa. Monitor the oxygen content and stop aerating when the oxygen content is lower than 0.8vol%.

[0056] (4) Turn on the feed switch to let the powder flow into the silo evenly. The weight of a feed is controlled at 10kg.

[0057] (5) Control the feed rate to 0.8kg / min, that is, the corresponding pneumatic pressure of the feeder is controlled at 0.2MPa.

[0058] (6) The high-frequency vibration screening process is used for screening, the vibration frequency is 35kHz, and the vibration deviation angle is 10°.

[0059] (7) Sieve for 60 minutes, and when the sievin...

Embodiment 2~9

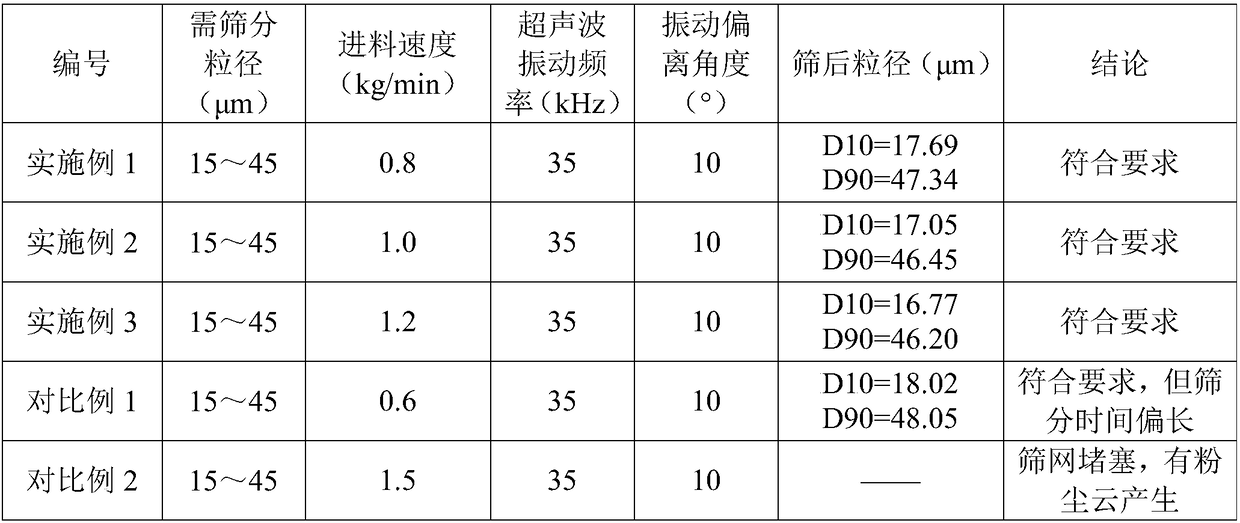

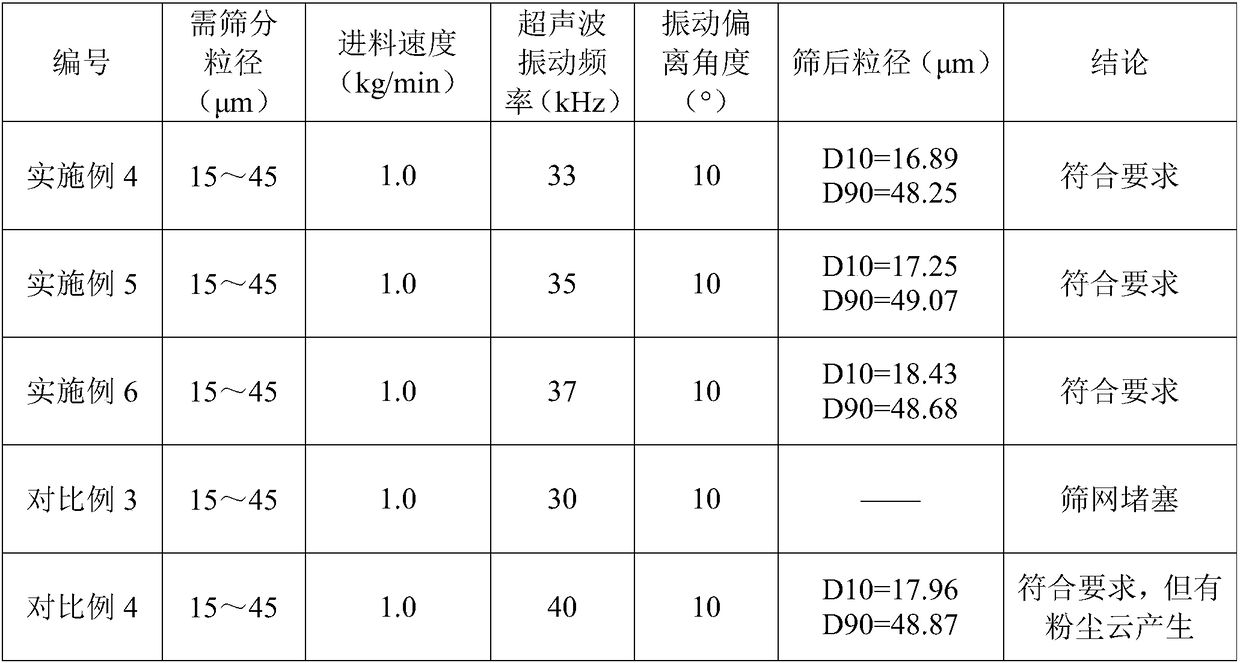

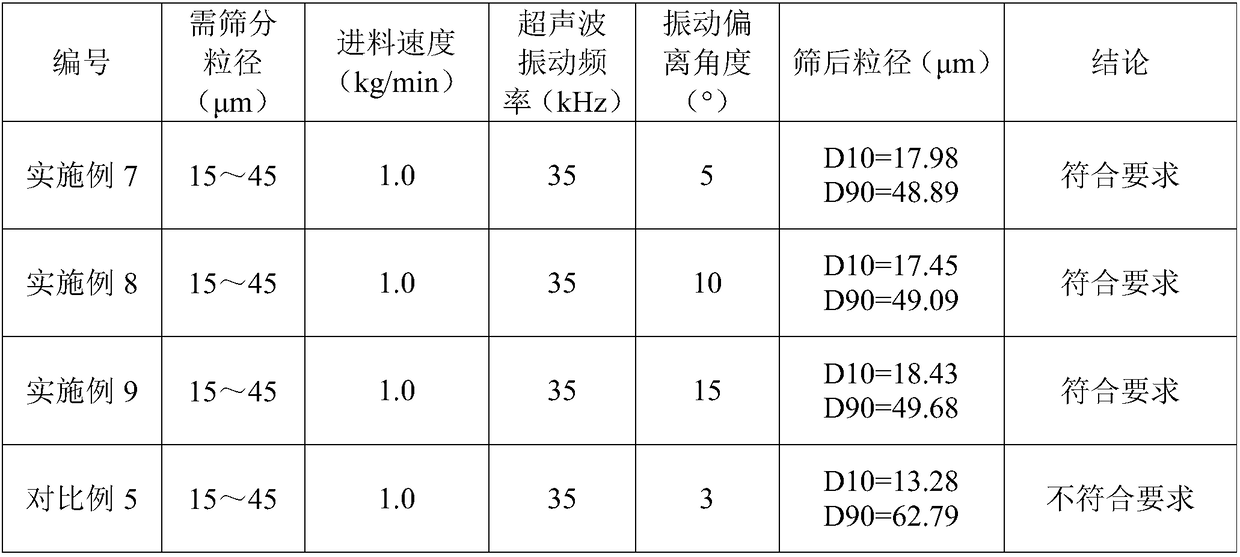

[0064] Using the method of Example 1, the control parameters were adjusted for screening, and the adjusted parameters and conclusions are shown in Tables 1-3.

Embodiment 10

[0073] Embodiment 10 Sieve the titanium alloy powder of 15~53 μm

[0074] (1) The metal powder raw material of 0-250 μm is prepared by an atomization method.

[0075] (2) Use 15 μm for the fine screen and 53 μm for the coarse screen. Screen area is 0.2m 2 .

[0076] (3) Fill the screening system with high-purity Ar at a rate of 9 L / min, which corresponds to the outlet pressure of the pressure reducing valve at 0.5 MPa. Monitor the oxygen content and stop aerating when the oxygen content is lower than 0.8vol%.

[0077] (4) Turn on the feed switch to let the powder flow into the silo evenly. The weight of a feed is controlled at 10kg.

[0078] (5) Control the feed rate to 1.0kg / min, that is, the corresponding pneumatic pressure of the feeder is controlled at 0.2MPa.

[0079] (6) The high-frequency vibration screening process is used for screening, the vibration frequency is 35kHz, and the vibration deviation angle is 10°.

[0080] (7) Sieve for 60 minutes, and when the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com