Aluminum alloy thin plate T-joint laser welding robot arm end welding execution end

A laser welding, aluminum alloy technology, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problem of few adjustment methods of wire feeding tube and air feeding tube, poor adjustment accuracy of wire feeding tube and air feeding end, The problems of low installation and uninstallation efficiency have achieved the effect of wide applicability, guaranteed stability, and convenient installation, maintenance, operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

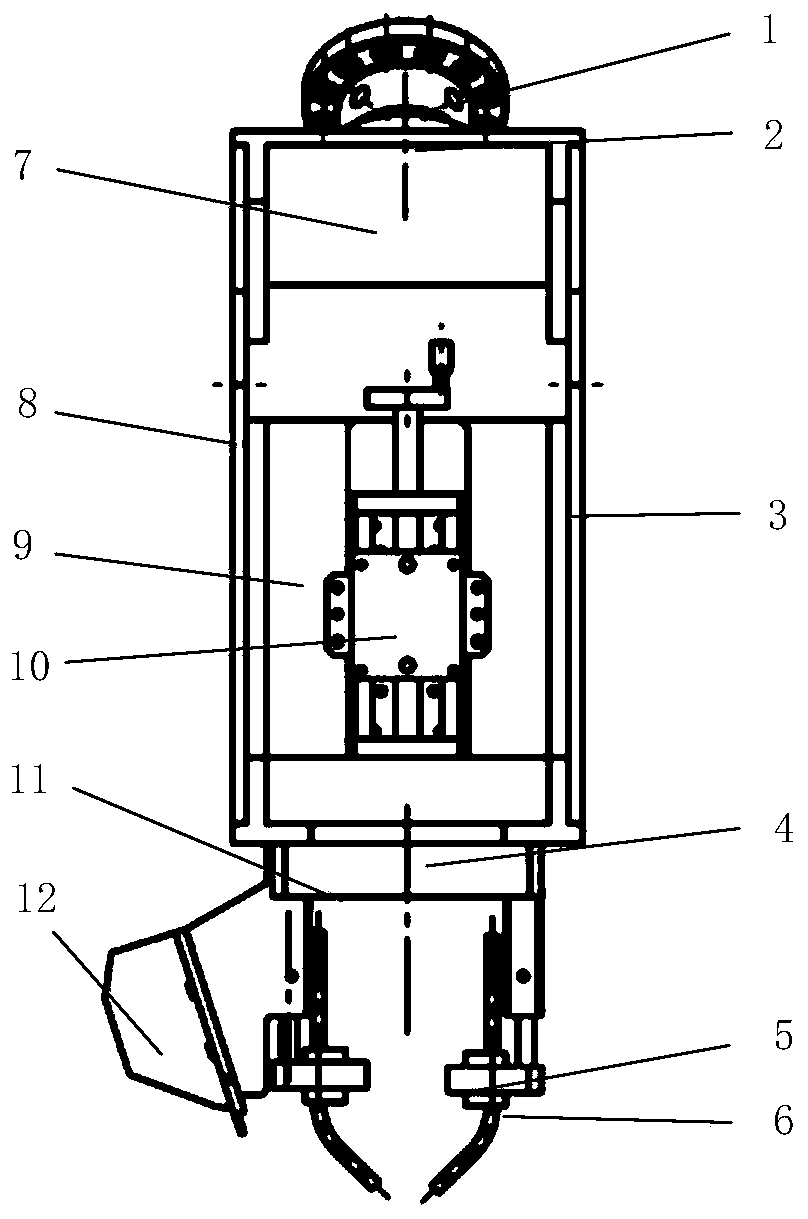

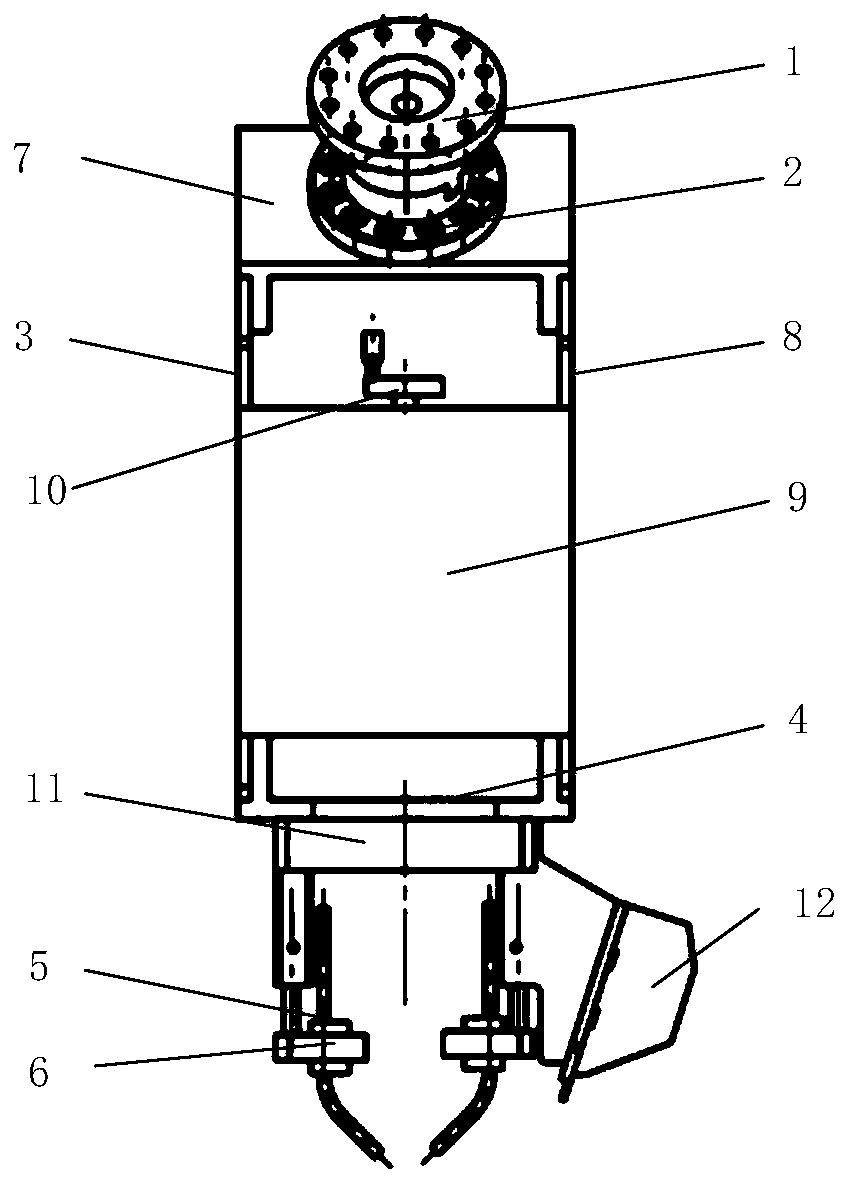

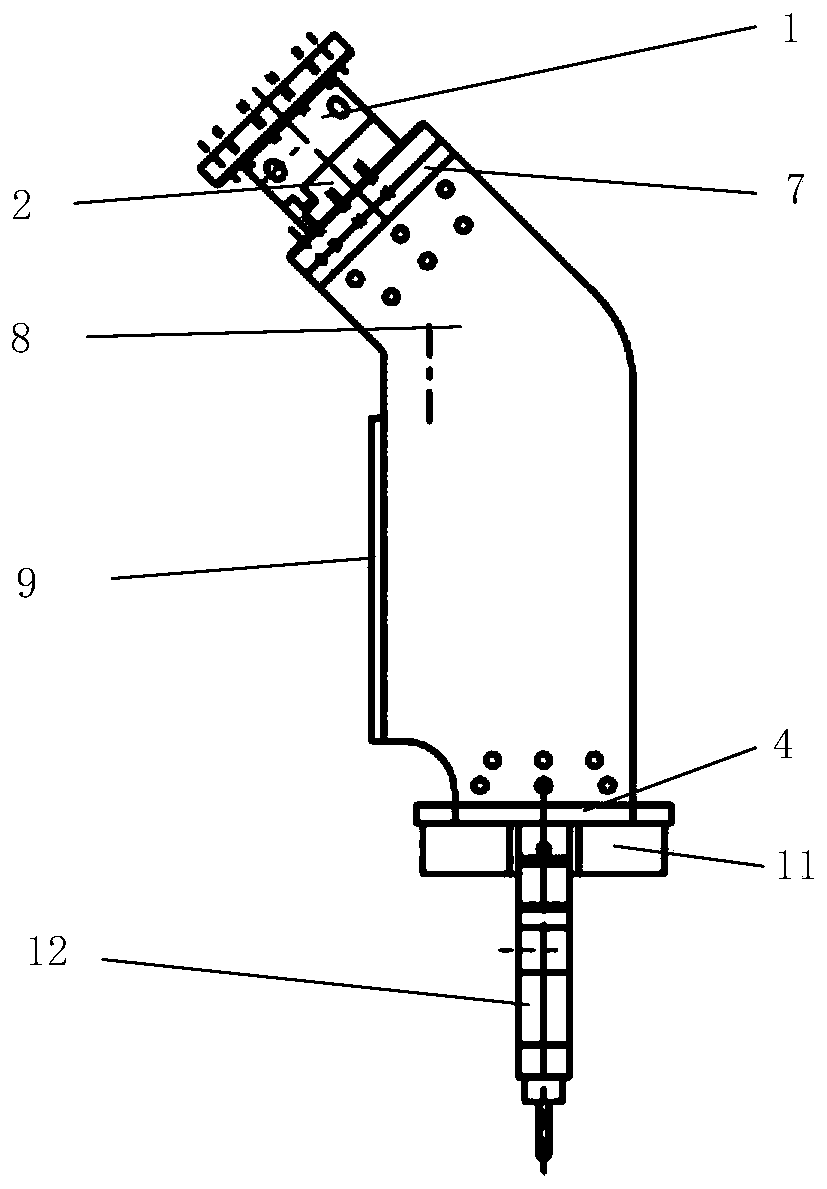

[0053] Utilize the welding execution end of the present invention and adopt the robot arm to realize the laser welding process, the robot selects the KUKAkr120 model, fully utilizes the flexibility of the robot arm to expand the application range of the welding execution end, Figure 5 It shows that the welding execution end of the present invention is compact in shape and has fewer parts. The welding execution end is mainly used for the double-beam laser welding process. This process needs to use the synchronous operation of the robot to form a welding posture with a certain angle that is symmetrical on both sides. At this time, in order to avoid The robot arm interferes, and the left and right side wall plates in the welding execution end are designed to have a certain angle, such as image 3 As shown, it is convenient to adjust the posture of the robot. At the same time, in order to improve the efficiency of the installation and disassembly of the welding execution end and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com