Automatic on-line laser cleaning device and method for dirt on large cavity inner wall

A technology of laser cleaning and cavity, which is applied in the direction of chemical instruments and methods, cleaning methods and appliances, laser welding equipment, etc., can solve the problems of no automatic and effective cleaning methods for the dirt on the inner wall of large cavities, and achieve cost saving and Time, the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present invention performs laser cleaning on the surface stains on the inner wall of the 7075 aluminum alloy circular cavity:

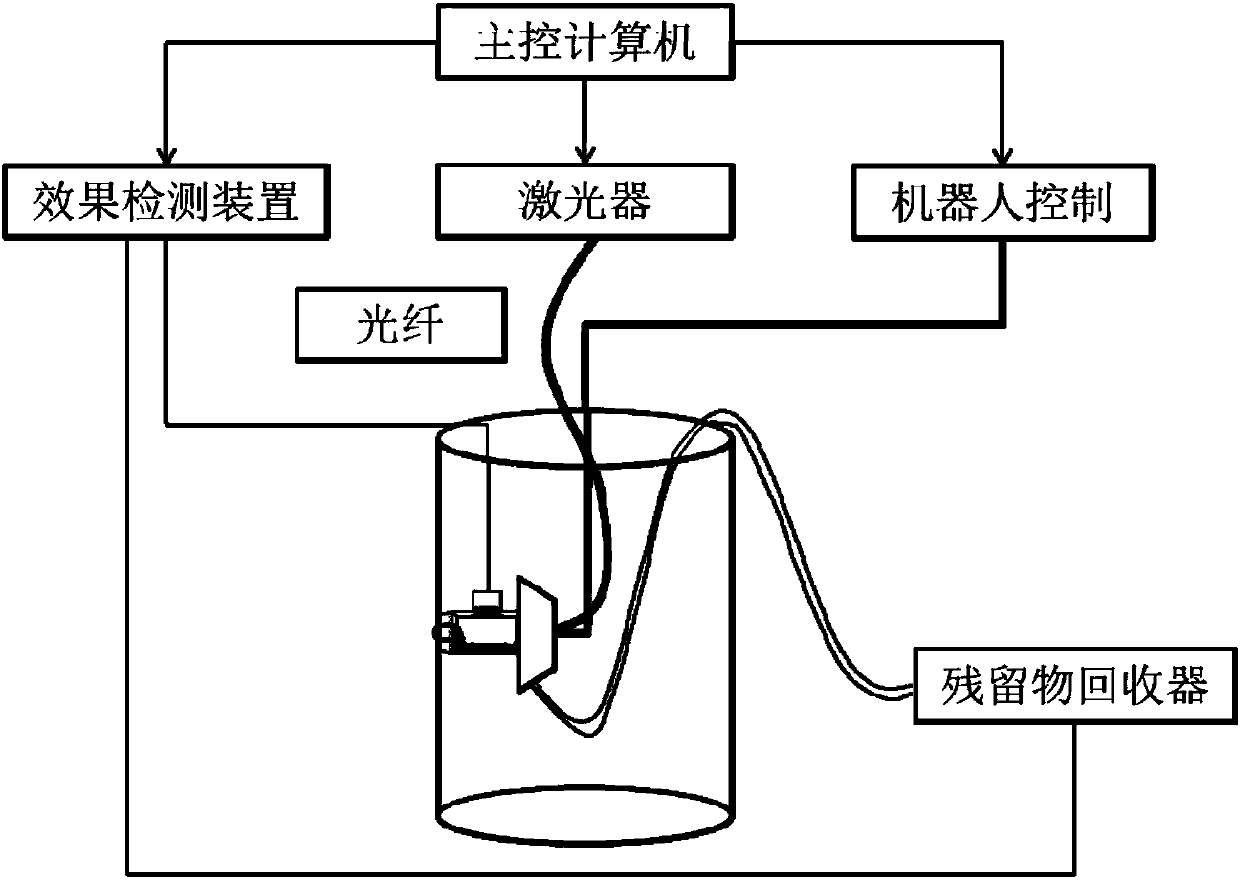

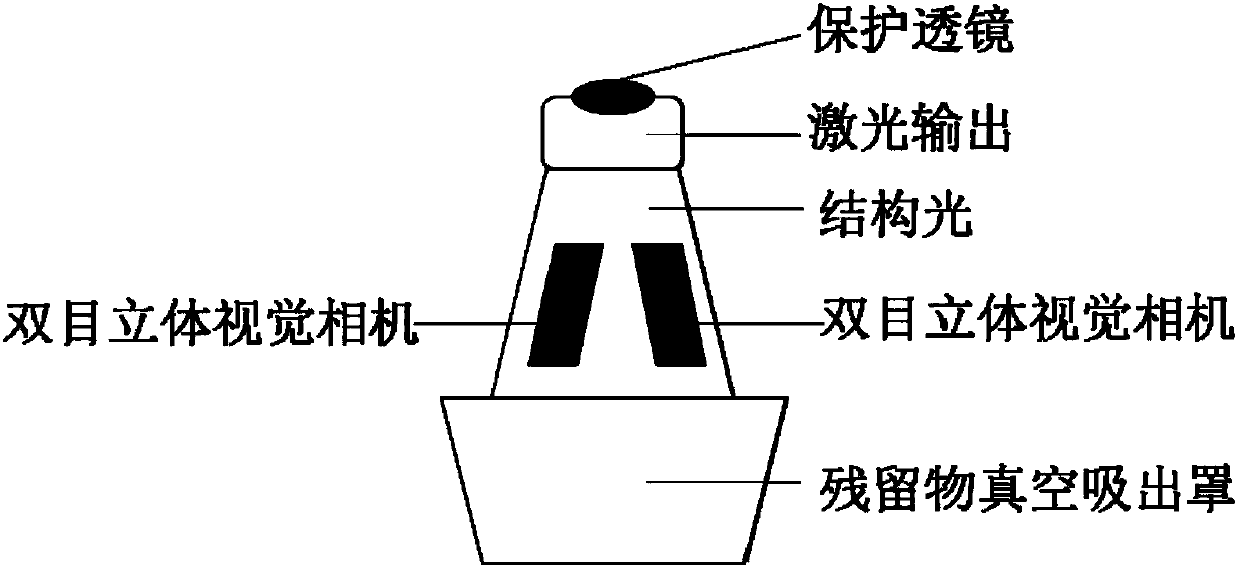

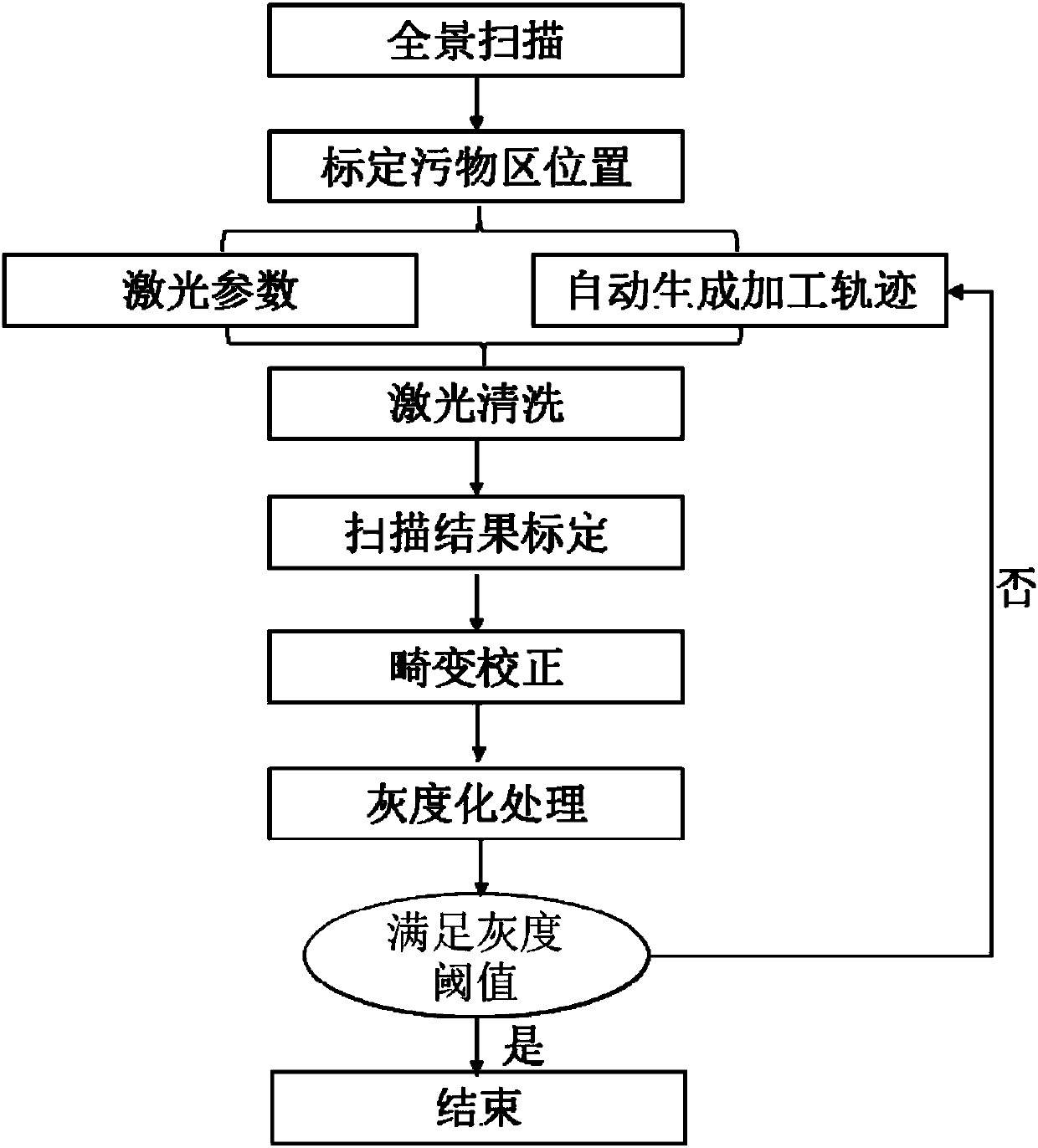

[0047] The present invention is a kind of laser cleaning automatic equipment, which is an open distributed control system, which realizes digitalization, automation and real-time control, and is controlled by industrial computer / PLC. The laser cleaning equipment mainly includes the following parts: main control computer , cleaning laser, clamping robot, effect monitoring device, optical fiber, vacuum residue recovery device, optical path shaping device, online monitoring device, etc., realize the information exchange of each link and the cooperative work of each component of the system, and through the status of the system Monitoring avoids major failures of important components. The console of the PC host integrates the entire operation control system, connects the laser, the robot control system and the effect detection device, and is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com