Environment-friendly mulch film capable of realizing sowing and preparation method thereof

A kind of mulching film and environmental protection technology, applied in the field of film products, can solve the problems of uncontrollable degradation cycle, increase of manpower and material resources, low reuse rate, etc., achieve the best biological/photocombined degradation function, reduce labor force, and completely degrade the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

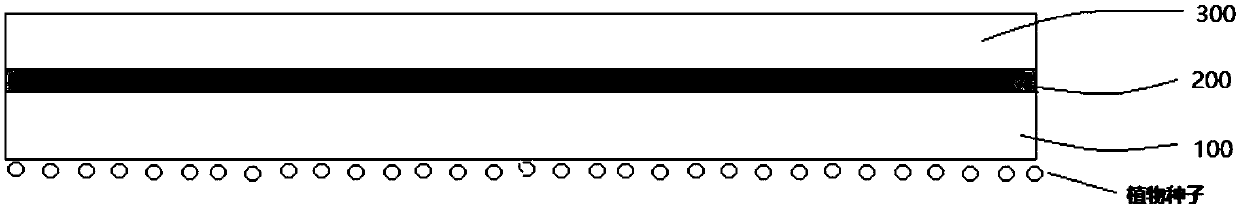

[0031] A kind of environment-friendly mulch film that can be sown in this embodiment, such as figure 1 As shown, it includes an adhesion-promoting biodegradable film layer 100, a compatible layer 200 and a photodegradable film layer 300;

[0032] Wherein, the thickening biodegradable film layer 100, in parts by weight, includes raw material components: 10 parts of PIB masterbatch, 90 parts of PLA;

[0033] Compatible layer 200, in parts by weight, includes raw material components: 70 parts of LLDPE resin, 30 parts of maleic anhydride grafted LLDPE;

[0034] Photodegradable film layer 300, in parts by weight, includes raw material components: 70 parts of composite resin (LLDPE / LDPE / mPE mass fraction ratio is 3:1:1), 20 parts of 1500 mesh active calcium carbonate, composite photodegradant grease Cerium oxide / TiO 2 1 part, PE wax 1 part.

[0035] The preparation method of above-mentioned sowing environment-friendly mulch film, comprises the steps:

[0036] After mixing the r...

Embodiment 2

[0038] In this embodiment, a seedable environmental protection mulch film includes a thickening biodegradable film layer, a compatible layer and a photodegradable film layer;

[0039] Wherein, the thickening biodegradable film layer includes raw material components in parts by weight: 20 parts of EVA, 80 parts of PBS;

[0040] The compatible layer, in parts by weight, includes raw material components: 90 parts of LLDPE resin, 10 parts of maleic anhydride grafted LLDPE;

[0041] The photodegradable film layer, in parts by weight, includes raw material components: 40 parts of composite resin (LLDPE / LDPE / mPE mass ratio is 4:1:1), 50 parts of 2500 mesh active calcium carbonate, composite photodegradant grease Cerium oxide / TiO 2 0.4 parts, PE wax 3 parts.

[0042] The preparation method of the above-mentioned seedable environment-friendly mulch film is the same as that in Example 1.

Embodiment 3

[0044] In this embodiment, a seedable environmental protection mulch film includes a thickening biodegradable film layer, a compatible layer and a photodegradable film layer;

[0045] Wherein, the thickened biodegradable film layer includes raw material components in parts by weight: 20 parts of PIB thickened masterbatch, 90 parts of PBAT;

[0046] The compatible layer, in parts by weight, includes raw material components: 80 parts of LDPE resin, 20 parts of maleic anhydride grafted LDPE;

[0047] The photodegradable film layer, in parts by weight, includes raw material components: 60 parts of composite resin (LLDPE / LDPE / mPE mass ratio is 3:1:1), 40 parts of 2000 mesh active calcium carbonate, composite photodegradant grease Ferric acid / TiO 2 0.6 parts, 2 parts of stearic acid.

[0048] The preparation method of the above-mentioned seedable environment-friendly mulch film is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com