Method for preparing crystal form A or crystal form D type avibactam product through crystallization

A technology for avibactam sodium and avibactam sodium salt is applied in the field of preparing crystal form A or crystal form D avibactam products, and achieves the effects of broad market prospect, wide application range and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

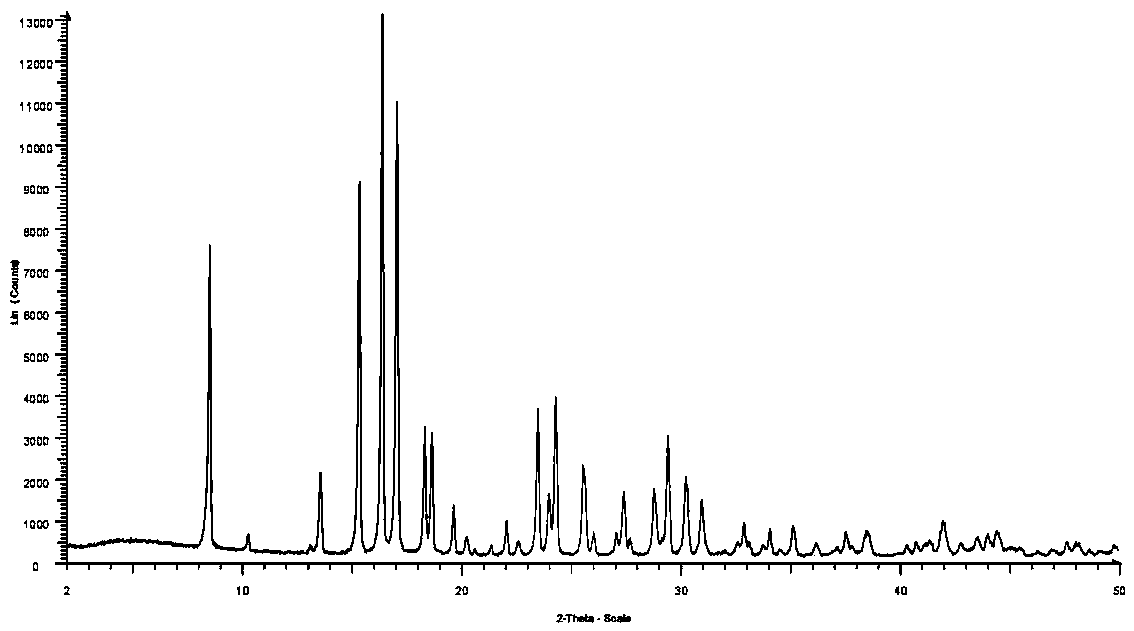

[0033] Use water (1 mL) and avibactam sodium salt (1 g) to prepare avibactam sodium salt solution, take absolute ethanol (9 mL), add avibactam sodium salt solution dropwise to absolute ethanol within 20 min, After the dropwise addition, stir at room temperature for 2 hours, then lower the temperature to 0-5°C and stir for 2 hours, filter, and wash the obtained filter cake with ethanol (5mL×2, that is, wash twice, each time with 5mL ethanol for washing), After washing, vacuum-dry at 45°C for 16 hours to obtain 0.83 g of white solid, with a yield of 83%. According to XRD analysis, it is the monohydrate "A" crystal form avibactam product, the XRD picture is as follows figure 1 shown.

Embodiment 2

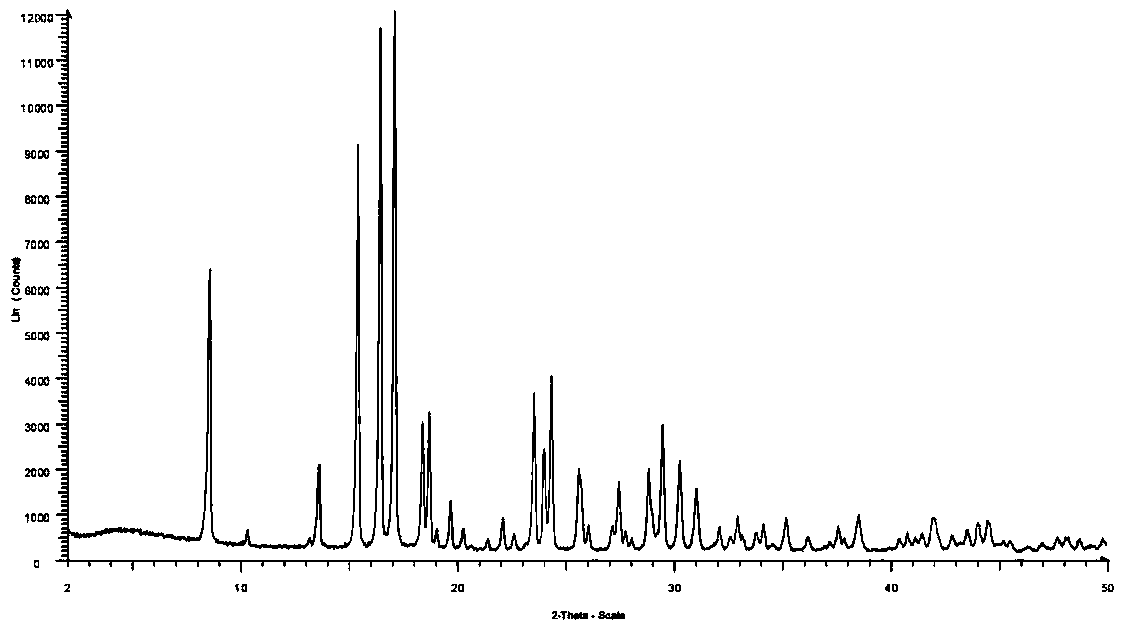

[0035] Use water (2 mL) and avibactam sodium salt (1 g) to prepare avibactam sodium salt solution, take absolute ethanol (8 mL), add avibactam sodium salt solution dropwise to absolute ethanol within 20 min, After the dropwise addition, stir at room temperature for 2 hours, then lower the temperature to 0-5°C and stir for 2 hours, filter, and wash the obtained filter cake with ethanol (5mL×2, that is, wash twice, each time with 5mL ethanol for washing), After washing, it was dried under vacuum at 45°C for 16 hours to obtain 0.18 g of white solid with a yield of 18%. According to XRD analysis, it is the monohydrate "A" crystal form avibactam product, the XRD picture is as follows figure 2 shown.

Embodiment 3

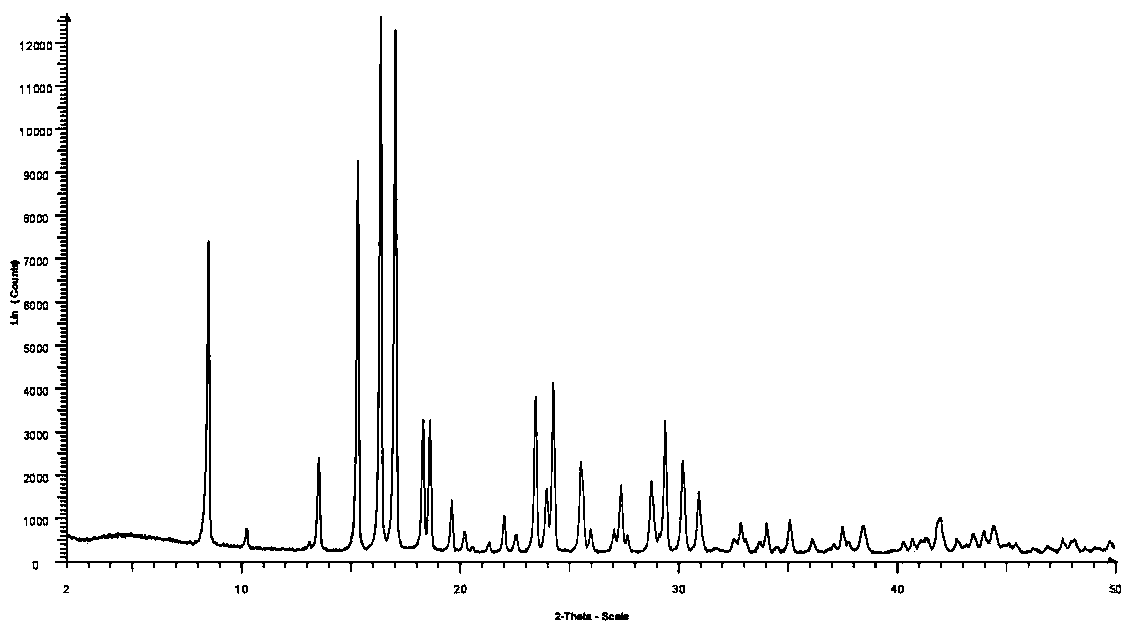

[0037] Use water (1mL) and avibactam sodium salt (1g) to prepare the avibactam sodium salt solution, take acetone (19mL), add the avibactam sodium salt solution to the acetone dropwise within 20min, after the dropwise addition , stirred at room temperature for 2h, then cooled to 0-5°C and stirred for 2h, filtered, and the obtained filter cake was washed with acetone (5mL×2, that is, washed twice, each time with 5mL acetone for washing), after washing, in Vacuum drying at 45°C for 16 hours gave 0.71 g of a white solid with a yield of 71%. According to XRD analysis, it is the monohydrate "A" crystal form avibactam product, the XRD picture is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com