Olefin polymerization catalyst spherical component, preparation method and applications thereof, olefin polymerization catalyst and applications thereof, and olefin polymerization method

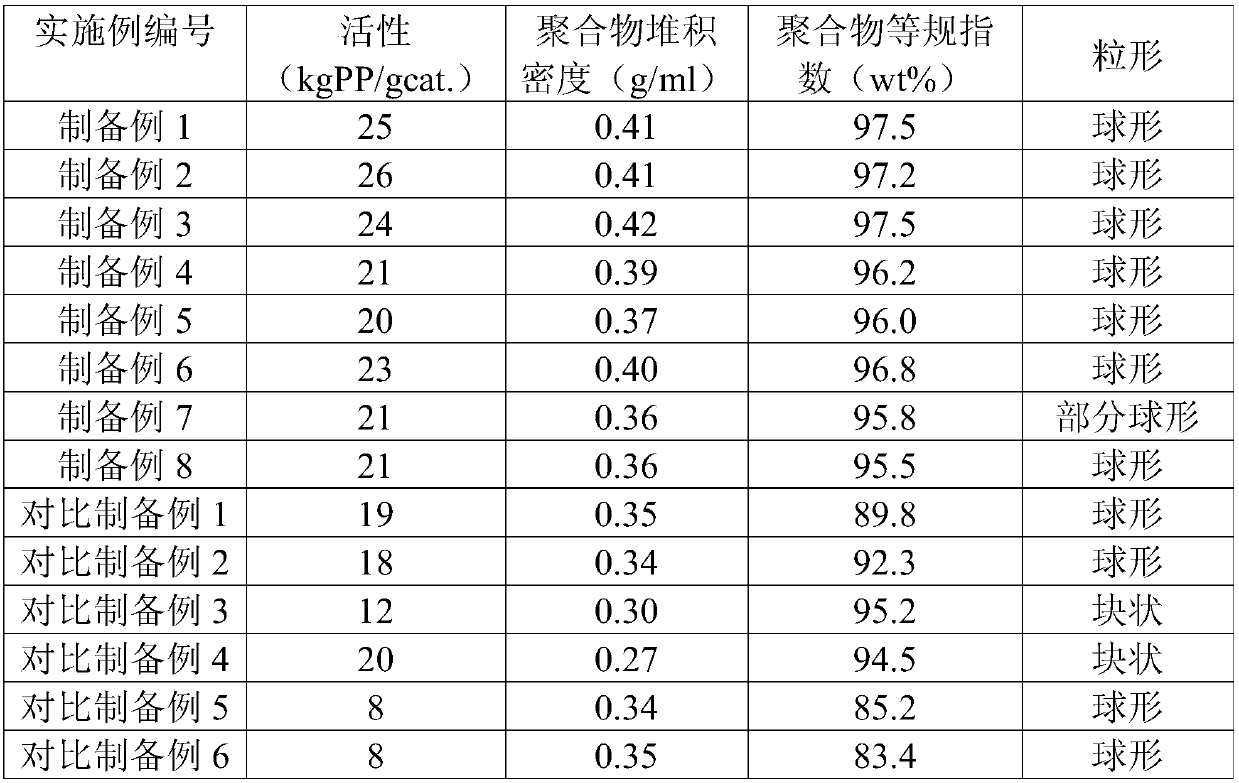

A technology of olefin polymerization and catalyst, applied in the field of spherical catalyst components for olefin polymerization, can solve the problems of low polymer bulk density and isotacticity, no industrial application value, low activity, etc., and achieve high bulk density and isotacticity High degree, saving production cost, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] On the one hand, the invention provides a kind of preparation method for the spherical catalyst component of olefin polymerization, the method comprises:

[0031] (1) In the presence of an inert solvent, the titanium compound, alkoxymagnesium, cyclic ether compound and alcohol compound are first contacted to obtain a uniform solution;

[0032] (2) second contacting the homogeneous solution obtained in step (1) with the titanium compound to precipitate a solid;

[0033] (3) In the presence of an inert solvent, conduct the third contact with the product obtained in step (2) with the titanium compound and the internal electron donor at a temperature of 120-150° C. to obtain a suspension containing the catalyst component.

[0034] According to the preparation method of the present invention, wherein, the amount of each raw material used to prepare the spherical catalyst component can be a conventional amount in the art, but under preferred conditions, the amount of alcohol ...

preparation example 1

[0081] This preparation example is used to illustrate the catalyst component provided by the invention and its preparation method

[0082] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, 5.8 grams of anhydrous magnesium ethylate, 140 milliliters of toluene, 3 milliliters of titanium tetrachloride, 9.6 milliliters of tetrahydrofuran, and 9.2 milliliters of butanol were added successively, at a temperature of 60 ° C. React for 2 hours, cool down to 10°C at a rate of 2°C / min, add 5 ml of titanium tetrachloride dropwise, then raise the temperature to 93°C at a rate of 0.5°C / min, keep the temperature constant for one hour, filter off the mother liquor, and wash with toluene for 2 time, then add 48 milliliters of titanium tetrachloride, 72 milliliters of chlorobenzene, keep the temperature at 130 ° C for 1 hour, add 48 milliliters of titanium tetrachloride, 72 milliliters of chlorobenzene, di-n-butyl phthalate (DNBP) 2.1 ml, kept at 130° C. for 1.5 ...

preparation example 2

[0084] This preparation example is used to illustrate the catalyst component provided by the invention and its preparation method

[0085] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, 5.8 grams of anhydrous butoxymagnesium, 176 milliliters of toluene, 3 milliliters of titanium tetrachloride, 9.6 milliliters of tetrahydrofuran, and 9.2 milliliters of amyl alcohol were added successively. , react for 2 hours, cool down to 20°C at a rate of 1°C / min, add 5 ml of titanium tetrachloride dropwise, then raise the temperature to 85°C at a rate of 0.3°C / min, keep the temperature for one hour, and then add titanium tetrachloride 48 ml, 72 ml of chlorobenzene, kept at 140°C for 1 hour, then added 48 ml of titanium tetrachloride, 72 ml of chlorobenzene, 2.1 ml of di-n-butyl phthalate (DNBP), kept at 120°C for 1.5 hours, filtered and washed 5 times with hexane, and the remaining solid product was vacuum-dried to obtain a solid titanium catalyst component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com