Ground negative-pressure oil extraction process and device thereof

A negative pressure, ground technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of large composition limitation and little improvement in emulsifying ability, and reduce oil-water interfacial tension and oil-water separation time. The effect of shortening and increasing emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

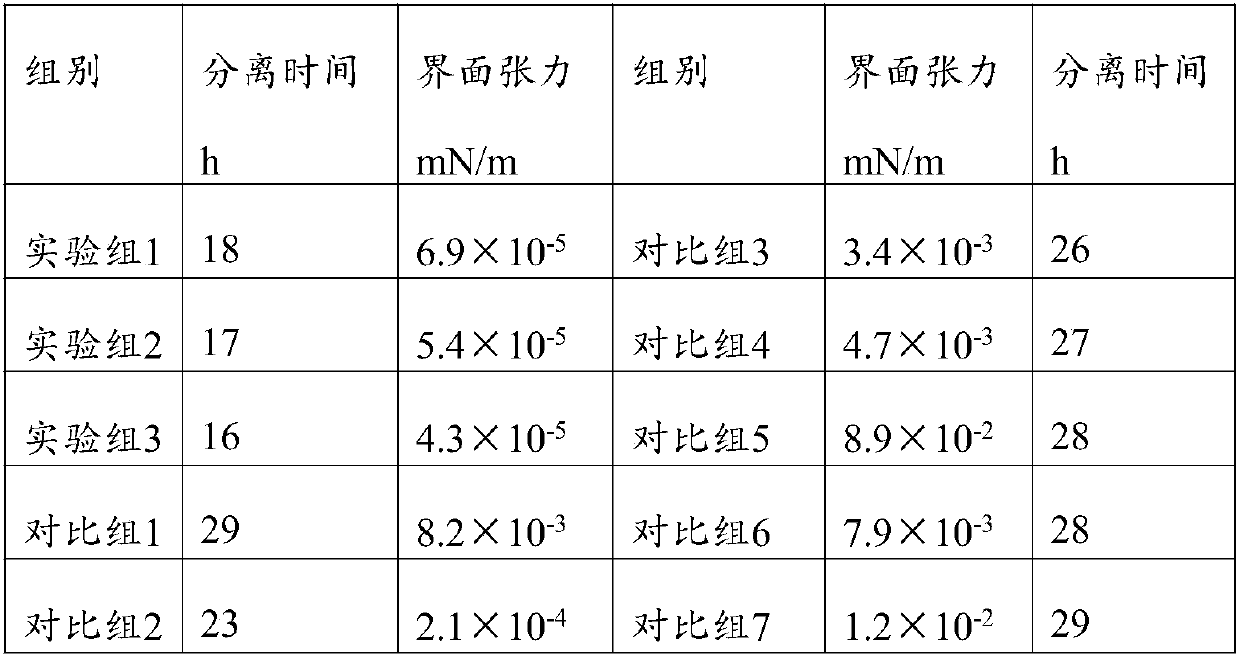

Examples

Embodiment 1

[0027] A surface negative pressure oil recovery process, the oil recovery method includes introducing the following composition into an oil well in the formation, and using the negative pressure method for oil recovery.

[0028] The composition includes a main agent and a synergist; the types and parts by weight of the various components in the main agent and the synergist can be selected as follows:

[0029] (1) 16 parts of wolfberry betaine, 4.5 parts of arylalkyl polyoxyethylene ether carboxy betaine, 4 parts of cetearyl glucoside, 15 parts of dodecyl sulfonate, phenyl ether thiazole carboxylate 7 parts, 8 parts of 6-p-toluidine naphthalene sulfonic acid, 3 parts of guar gum, 4 parts of lignin;

[0030] (2) 13 parts of wolfberry betaine, 2.5 parts of arylalkyl polyoxyethylene ether carboxy betaine, 3 parts of cetearyl glucoside, 20 parts of dodecylsulfonate, phenyl ether thiazole carboxylate 10 parts, 5 parts of 6-p-toluidine naphthalene sulfonic acid, 2 parts of diphenyl ...

Embodiment 2

[0037] For the composition in Example 1, its preparation method is: betaine derivatives, diphenyl ethers, heterocyclic salts, naphthyl sulfonates, glucoside derivatives, and alkyl sulfonates in the main agent are Add the proportions in Example 1 to water one by one, that is, add one type and then the other, stir at 60-80 degrees Celsius for 1-3 minutes, then add the ingredients of the synergist, continue to stir and mix until it is in an emulsified state Stirring was stopped to obtain the composition. In the composition, the proportion of water accounts for 20-30% of the total weight.

Embodiment 3

[0039] For the negative pressure oil production method in embodiment 1, can also comprise the following steps: the deep well pump that oil production is used is arranged in the oil well to be produced, then packer is set between 70~150 meters above the deep well pump, then in A negative pressure space is formed below the packer, and then negative pressure oil recovery is carried out. For other commonly used oil recovery devices or conventional processes, reference may be made to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com