Defect detection device and detection and repair method in laser metal cladding rapid prototyping process

A technology for forming process and defect detection, applied in the direction of measuring device, optical radiation measurement, radiation pyrometry, etc., can solve the problems of metal parts fatigue fracture, catastrophic consequences, depth cannot be measured, etc., and achieve the effect of good reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

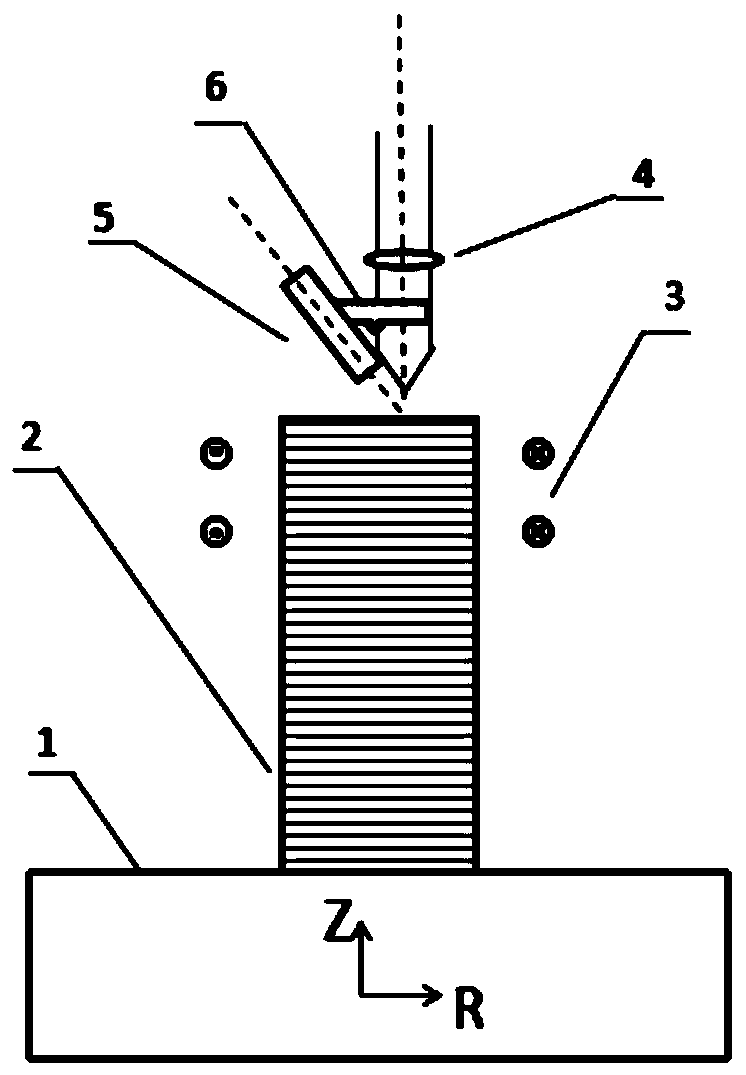

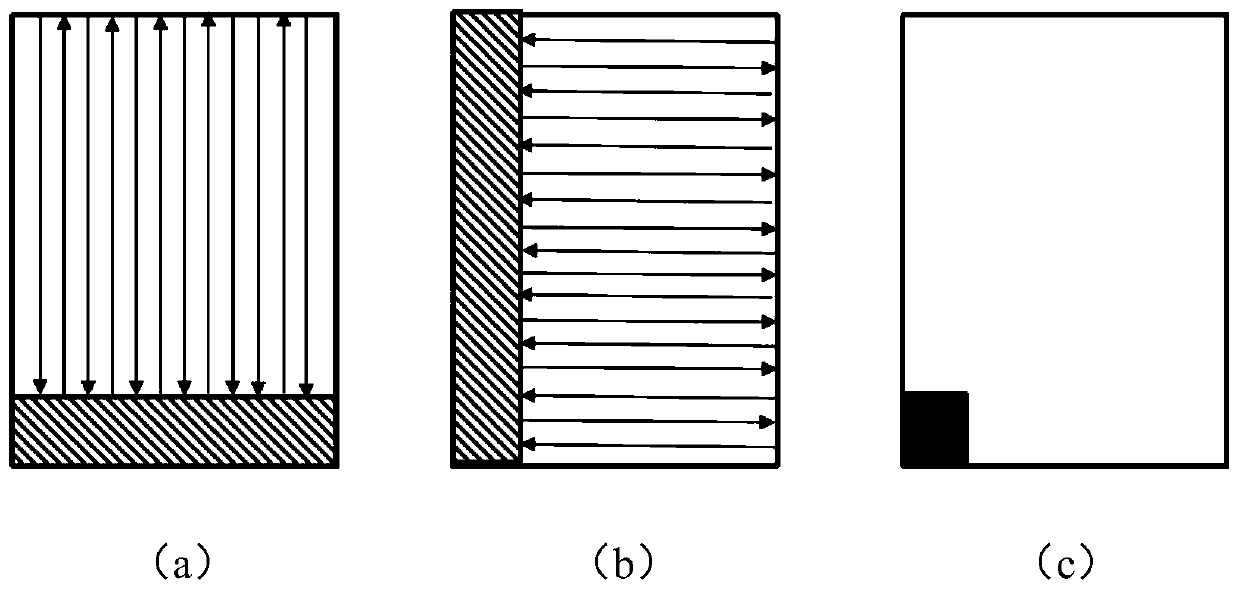

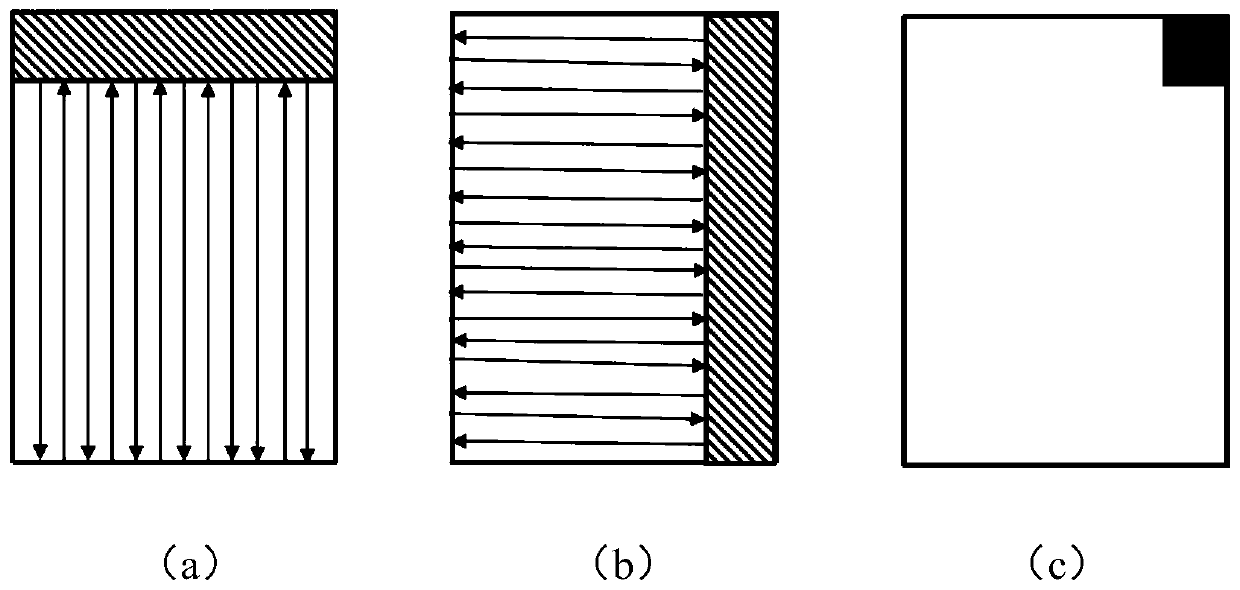

[0035] see Figure 1-7 , the defect detection device in the laser metal cladding rapid prototyping process of the present invention includes a base plate 1 for placing a molded part 2, and a spray head 4 located above the base plate 1, a clamp 6 is installed on the print head 4, and can rotate, and the clamp 6 An infrared monochromatic pyrometer 5 is installed on it; the outer side of the molded part 2 is provided with an induction coil 3 adapted to its contour shape. The spray head 4 is composed of a laser, a powder feeder and a cooling water device. The cross-sectional shape and size of the induction coil 3 are determined according to the shape of the molded part 2 . The cross-sectional shape of the induction coil 3 is circular or square. The induction coil 3 is made of a copper tube with an outer diameter of 3mm-10mm. After the coil is made, the inner surface is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com