On-line preparation method of hydrophobic yarn for embedded composite spinning

A composite spinning and hydrophobic technology, applied in the field of textile processing, can solve problems such as prolonging the production cycle, complicating the production process, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

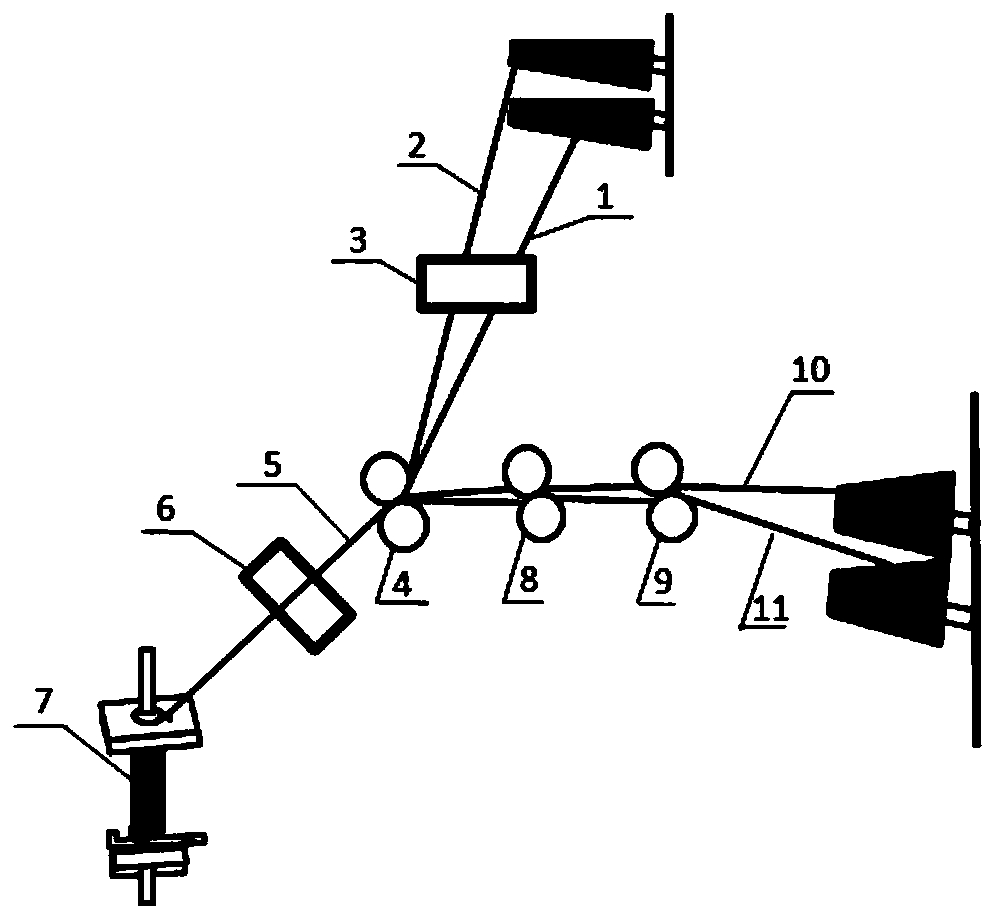

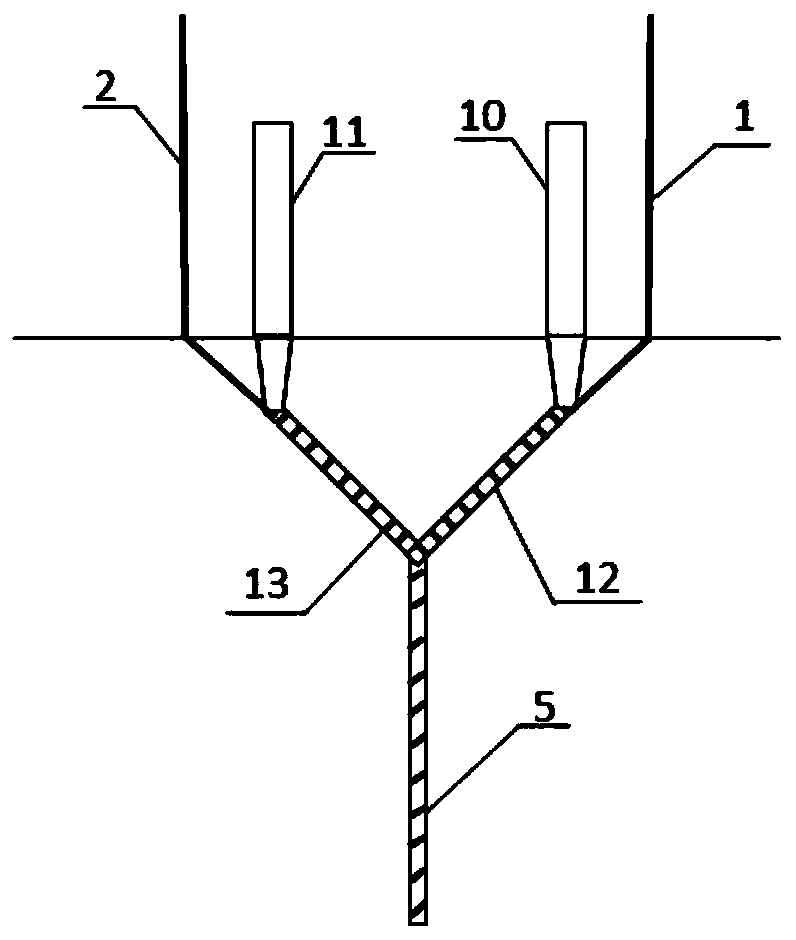

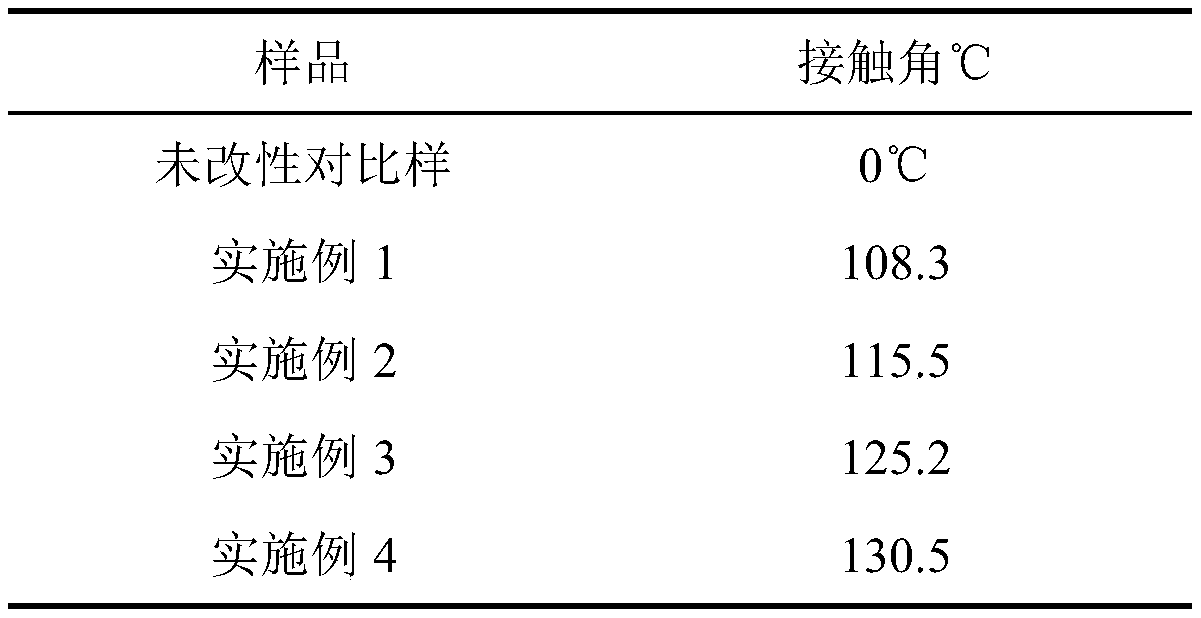

[0015] A modifying device is installed in the running path of the first viscose filament and the second viscose filament on the ring spinning frame. The modifying device consists of a flow control device and a wetting device. The flow control device adopts a syringe pump and the wetting device The sponge wetting device is used, the hose is connected between the flow control device and the wetting device, the flow control device adjusts the flow rate of the modified liquid, the wetting device applies the modified liquid to the two viscose filaments, and the hydrophobic finishing agent is made of anhydrous It is formulated from ethanol and polyorganosiloxane, and the mass ratio of absolute ethanol to polyorganosiloxane is 95:5. The flow rate of the flow control device in the modification device is 40 drops / min. A drying device is installed between the upper front roller of the ring spinning frame and the spinning bobbin. The drying device adopts a resistance heater. The first vis...

Embodiment 2

[0017] A modifying device is installed in the running path of the first viscose filament and the second viscose filament on the ring spinning frame. The modifying device consists of a flow control device and a wetting device. The flow control device adopts a peristaltic pump and the wetting device The sponge wetting device is used, the hose is connected between the flow control device and the wetting device, the flow control device adjusts the flow rate of the modified liquid, the wetting device applies the modified liquid to the two viscose filaments, and the hydrophobic finishing agent is made of anhydrous It is formulated from ethanol and polyorganosiloxane, and the mass ratio of absolute ethanol to polyorganosiloxane is 85:15. The flow rate of the flow control device in the modification device is 50 drops / min, and a drying device is installed between the front roller and the spinning bobbin on the ring spinning frame. The drying device adopts an infrared radiation heater. T...

Embodiment 3

[0019] A modifying device is installed in the running path of the first viscose filament and the second viscose filament on the ring spinning frame. The modifying device consists of a flow control device and a wetting device. The flow control device adopts a syringe pump and the wetting device The sponge wetting device is used, the hose is connected between the flow control device and the wetting device, the flow control device adjusts the flow rate of the modified liquid, the wetting device applies the modified liquid to the two viscose filaments, and the hydrophobic finishing agent is made of anhydrous It is formulated from ethanol and polyorganosiloxane, and the mass ratio of absolute ethanol to polyorganosiloxane is 75:25. The flow rate of the flow control device in the modification device is 60 drops / min, and a drying device is installed between the front roller and the spinning bobbin on the ring spinning frame. The drying device adopts a resistance heater. The first visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com