Damper for wind power generation

A damper and damping technology, used in wind power generation, wind turbines, engines, etc., can solve problems such as smooth engine room impact, and achieve the effects of stable friction damping, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described now in conjunction with accompanying drawing.

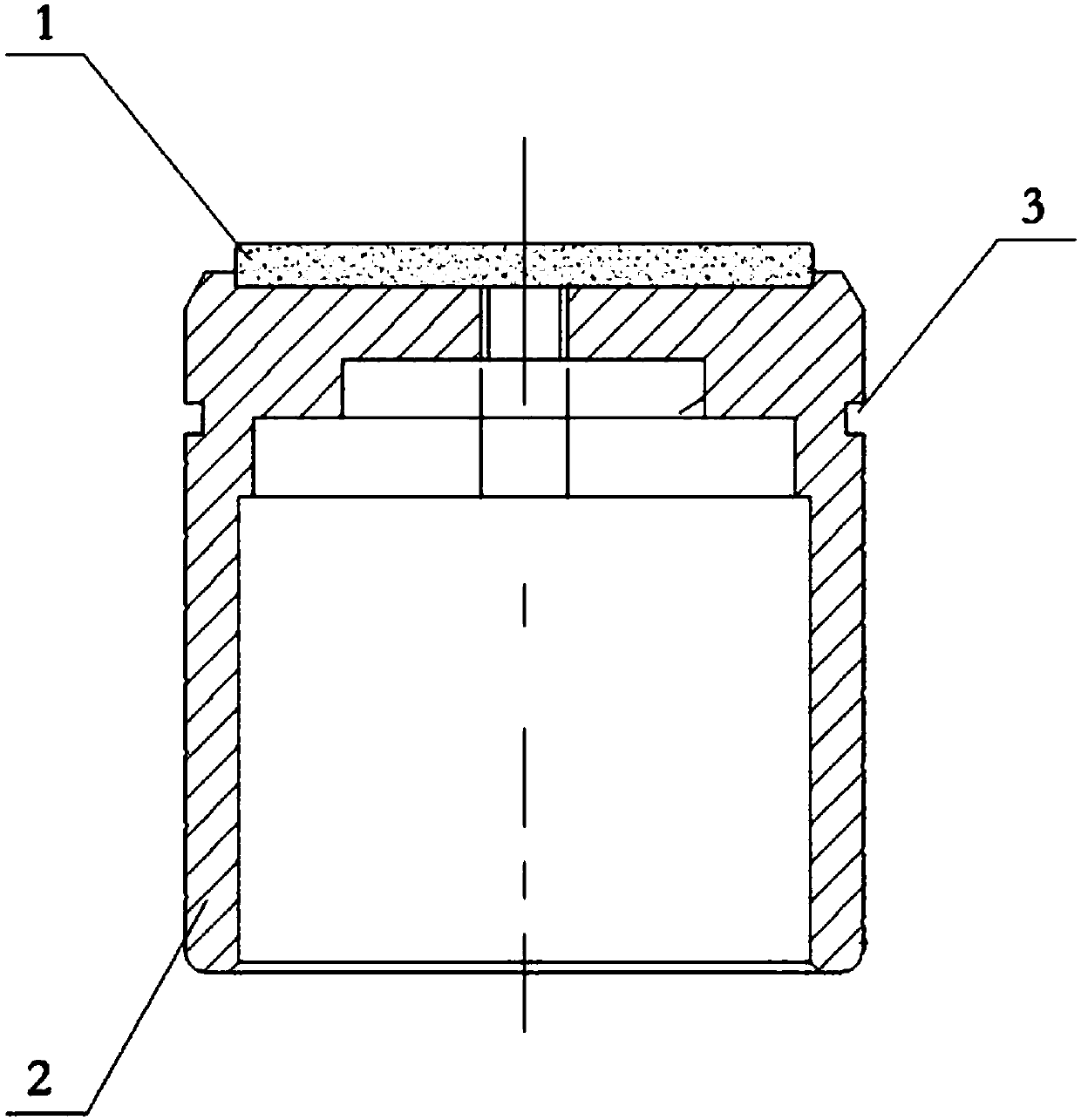

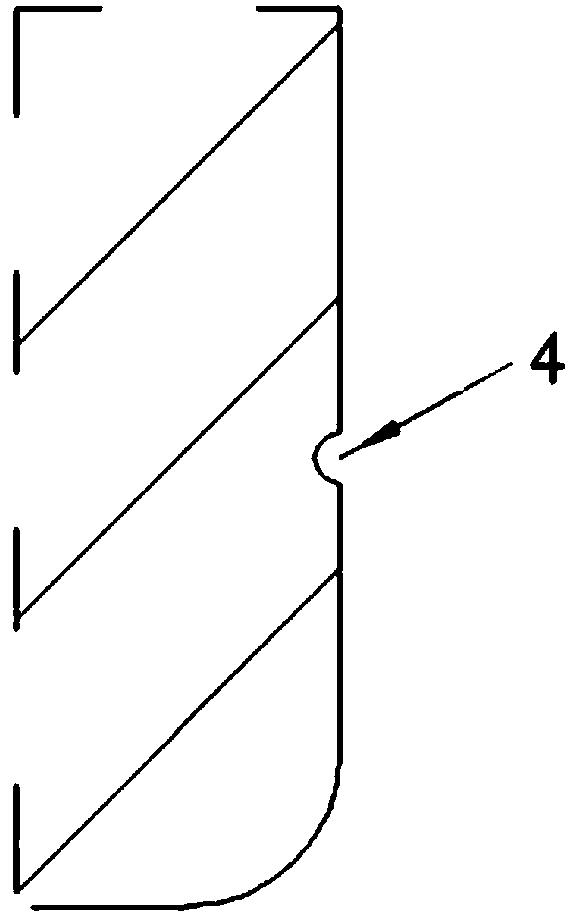

[0014] see figure 1 and figure 2 , figure 1 , figure 2 Shown is an embodiment of the present invention, which is composed of a damping friction plate 1 and a cylinder 2 with self-lubricating properties. Among them, the damping friction plate 1 is composed of the following raw materials in parts by mass: graphite powder 0.5%-23.5%, petroleum coke 0.1%-15%, ultra-fine tin bronze powder and / or brass powder 0.1%-5%, Asphalt 0.2%-25%, the rest is filling powder. In addition, vacuum impregnation resin 2% is included. The damping friction plate 1 made of the above ingredients can be easily and firmly combined with other materials, and the adhesion is firm; it has self-lubricating properties, and the equipment (parts) slides lightly; the friction coefficient is moderate, the braking is stable, and there is less dust; Excellent wear resistance, long service life; thermal shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com