Ultrahigh-water-resistance binder for tiles and marbles

An adhesive and marble technology, which is applied in the research and development field of adhesives for tiles and marbles, can solve the problems of unstable waterproof performance, leakage, and hollow walls falling off, achieving super waterproof and bonding performance, and easy to use. , the effect of inhibiting cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

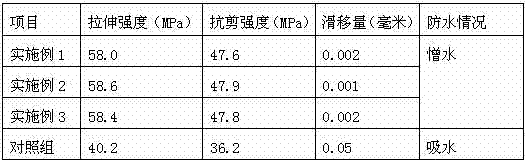

Examples

Embodiment 1

[0015] A super-waterproof adhesive for ceramic tiles and marble, which is made of the following ingredients in parts by weight: 35 parts of silicone modified styrene-acrylic emulsion, 10 parts of polyvinyl alcohol, 8 parts of polyacrylamide, anhydrous chlorine Calcium 2.5 parts, sodium sulfate 1.2 parts, filler 0.5 parts, methyl cellulose ether 0.30 parts, starch ether 0.25 parts, polypropylene monofilament fiber 0.15 parts, triethanolamine 0.10 parts; the binder and modified sulfate cement Used together, according to 1.0% of the mass of modified sulfate cement, adjust the viscosity of the mortar to 7 cm.

[0016] As a further improvement to the above solution, the methyl cellulose ether has a viscosity of 40000-mpa·s and a fineness of 150 mesh.

[0017] As a further improvement to the above solution, the length of the polypropylene monofilament fiber is between 8-10 mm.

[0018] As a further improvement to the above scheme, the filler is composed of the following components ...

Embodiment 2

[0022] A super-waterproof adhesive for ceramic tiles and marble, which is made of the following components in parts by weight: 40 parts of silicone modified styrene-acrylic emulsion, 11 parts of polyvinyl alcohol, 9 parts of polyacrylamide, anhydrous chlorine Calcium 2.8 parts, sodium sulfate 1.3 parts, filler 0.6 parts, methyl cellulose ether 0.33 parts, starch ether 0.30 parts, polypropylene monofilament fiber 0.16 parts, triethanolamine 0.11 parts; the binder and modified sulfate cement Used together, according to 1.1% of the mass of modified sulfate cement, adjust the viscosity of the mortar to 8 cm.

[0023] As a further improvement to the above solution, the methyl cellulose ether has a viscosity of 42000 mpa·s and a fineness of 160 mesh.

[0024] As a further improvement to the above solution, the length of the polypropylene monofilament fiber is between 8-10 mm.

[0025] As a further improvement to the above scheme, the filler is composed of the following components i...

Embodiment 3

[0029] An adhesive for ceramic tiles and marble with super waterproof performance, which is made of the following components in parts by weight: 45 parts of silicone modified styrene-acrylic emulsion, 12 parts of polyvinyl alcohol, 10 parts of polyacrylamide, anhydrous chlorine Calcium 3.0 parts, sodium sulfate 1.4 parts, filler 0.8 parts, methyl cellulose ether 0.35 parts, starch ether 0.35 parts, polypropylene monofilament fiber 0.18 parts, triethanolamine 0.12 parts; the binder and modified sulfate cement Used together, according to 1.2% of the mass of modified sulfate cement, adjust the viscosity of the mortar to 9 cm.

[0030] As a further improvement to the above solution, the methyl cellulose ether has a viscosity of 43000 mpa·s and a fineness of 180 mesh.

[0031] As a further improvement to the above solution, the length of the polypropylene monofilament fiber is between 8-10 mm.

[0032] As a further improvement to the above scheme, the filler is composed of the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com