Device and method for preparing aluminium oxide short staple preform

A technology of aluminum oxide and short fibers, which is applied in the field of devices for preparing aluminum oxide short fiber preforms, can solve problems such as incomplete transformation of silica sol, delamination, and cracking of preforms, and shorten the preparation cycle and improve Preparation efficiency, rapid preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

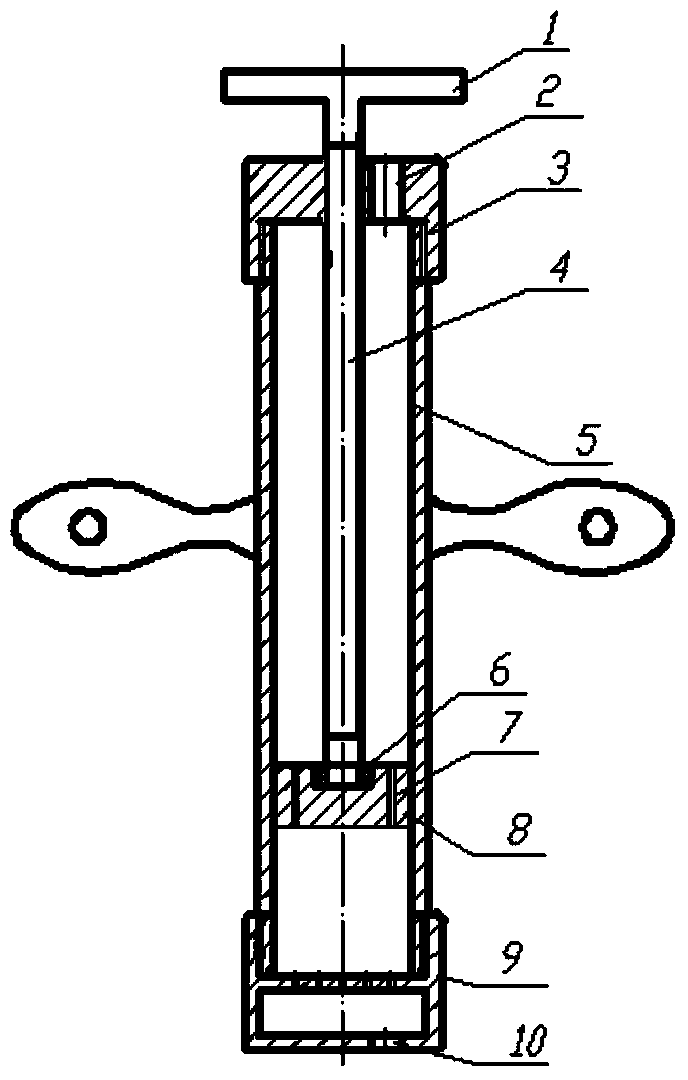

Image

Examples

Embodiment 2

[0034] Step 1. Discontinuous Al 2 o 3sf Pretreatment and screening of short fibers.

[0035] (1) First of all, if you want to make a prefabricated body with a volume fraction of 25%, according to the quantitative Al 2 o 3 Short fiber, the continuous Al 2 o 3 The fibers were cut into discontinuous Al with a length of 5 mm 2 o 3 fiber, this method can effectively eliminate the discontinuous Al 2 o 3 Agglomeration of short fibers into clusters.

[0036] (2) Use a mechanical stirring device to break up the agglomerated fibers in advance by jogging. When the mixed slurry is dispersed evenly, then switch to low-speed stirring for 15 minutes to remove the impurities suspended in the upper layer of the slurry and the slag in the mixed slurry. spheres to form turbulent flow to facilitate the Al 2 o 3 Subsequent processing of fibers. Use a filter and screening device to filter and fish out, repeat 2 to 3 times as needed.

[0037] Step 2. Mix Al 2 o 3 The short fiber slurr...

Embodiment 3

[0049] Step 1. Discontinuous Al 2 o 3sf Pretreatment and screening of short fibers.

[0050] (1) First of all, if you want to make a prefabricated body with a volume fraction of 25%, according to the quantitative Al 2 o 3 Short fiber, the continuous Al 2 o 3 The fiber is cut into discontinuous Al with a length of about 10mm 2 o 3 fiber, this method can effectively eliminate the discontinuous Al 2 o 3 Agglomeration of short fibers into clusters.

[0051] (2) Use a mechanical stirring device to break up the agglomerated fibers in advance by jogging. When the mixed slurry is dispersed evenly, then switch to low-speed stirring for about 15 minutes to remove the impurities suspended in the upper layer of the slurry and the mixed slurry. Slag balls, making them form turbulent flow to facilitate Al 2 o 3 Subsequent processing of fibers. Use a filter and screening device to filter and fish out, repeat 2 to 3 times as needed.

[0052] Step 2. Mix Al 2 o 3 The short fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com