Magnesian expanding agent shrinkage-compensating concrete and preparation method thereof

A technology for compensating shrinkage and concrete, applied in the field of building materials, can solve the problems of insufficiency, concrete cracking, poor volume stability of cement, etc., and achieve the effect of inhibiting cracking and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

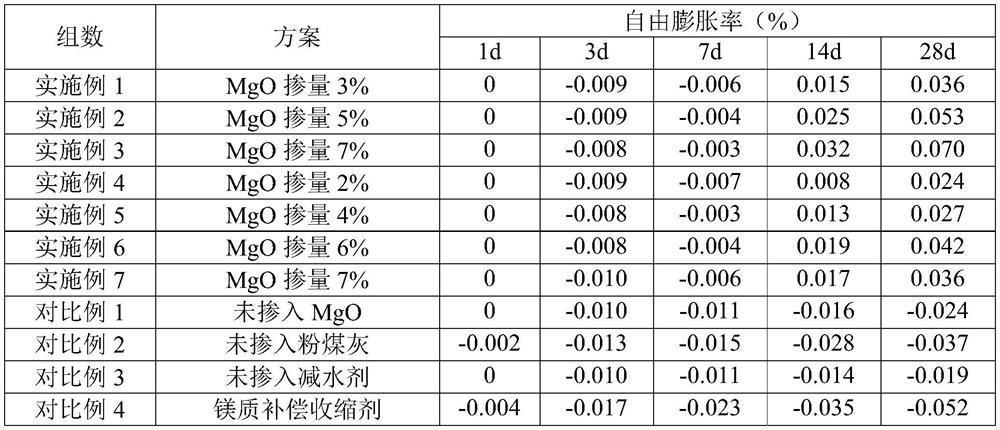

Examples

Embodiment 1

[0022] A magnesia expansion agent shrinkage compensation concrete, prepared from the following raw materials in parts by weight: 218 parts of cement, 93 parts of fly ash, 3.11 parts of water reducing agent, 9.33 parts of magnesium oxide, 896 parts of siliceous rock artificial sand, 657 parts of 20-40mm medium stone, 438 parts of 5-20mm small stone and 140 parts of water.

[0023] The water reducer is composed of methallyl polyoxyethylene ether, sodium propylene sulfonate, and maleic anhydride as monomers, and is compounded with hydrogen peroxide, sodium thiosulfate, and acrylic acid. Synthesized by radical polymerization and dried in vacuum.

[0024] The mass ratio of methallyl polyoxyethylene ether, sodium propylene sulfonate, maleic anhydride, hydrogen peroxide, sodium thiosulfate and acrylic acid in the water reducer is 30:20:12:5:3:15.

Embodiment 2

[0026] A magnesia expansion agent shrinkage compensation concrete, prepared from the following raw materials in parts by weight: 218 parts of cement, 93 parts of fly ash, 3.11 parts of water reducing agent, 15.55 parts of magnesium oxide, 896 parts of siliceous rock artificial sand, 657 parts of 20-40mm medium stone, 438 parts of 5-20mm small stone and 140 parts of water.

[0027] The water reducer is composed of methallyl polyoxyethylene ether, sodium propylene sulfonate, and maleic anhydride as monomers, and is compounded with hydrogen peroxide, sodium thiosulfate, and acrylic acid. Synthesized by radical polymerization and dried in vacuum.

[0028] The mass ratio of methallyl polyoxyethylene ether, sodium propylene sulfonate, maleic anhydride, hydrogen peroxide, sodium thiosulfate and acrylic acid in the water reducer is 30:20:12:5:3:15.

Embodiment 3

[0030] A magnesia expansion agent shrinkage compensation concrete, prepared from the following raw materials in parts by weight: 218 parts of cement, 93 parts of fly ash, 3.11 parts of water reducing agent, 21.77 parts of magnesium oxide, 896 parts of siliceous rock artificial sand, 657 parts of 20-40mm medium stone, 438 parts of 5-20mm small stone and 140 parts of water.

[0031] The water reducer is composed of methallyl polyoxyethylene ether, sodium propylene sulfonate, and maleic anhydride as monomers, and is compounded with hydrogen peroxide, sodium thiosulfate, and acrylic acid. Synthesized by radical polymerization and dried in vacuum.

[0032] The mass ratio of methallyl polyoxyethylene ether, sodium propylene sulfonate, maleic anhydride, hydrogen peroxide, sodium thiosulfate and acrylic acid in the water reducer is 30:20:12:5:3:15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com