SiO2/alpha-Al2O3 ceramic composite coating with high bonding strength and low-temperature preparation method thereof

A combination strength and ceramic composite technology, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve the problems of uneven structure, stress corrosion of structural materials, high cost, etc., so as to prevent uneven stress and improve Bonding strength and effect of improving adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

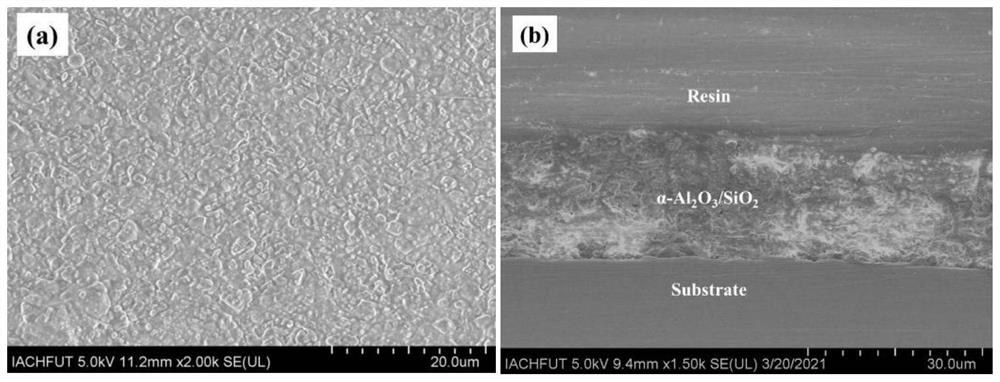

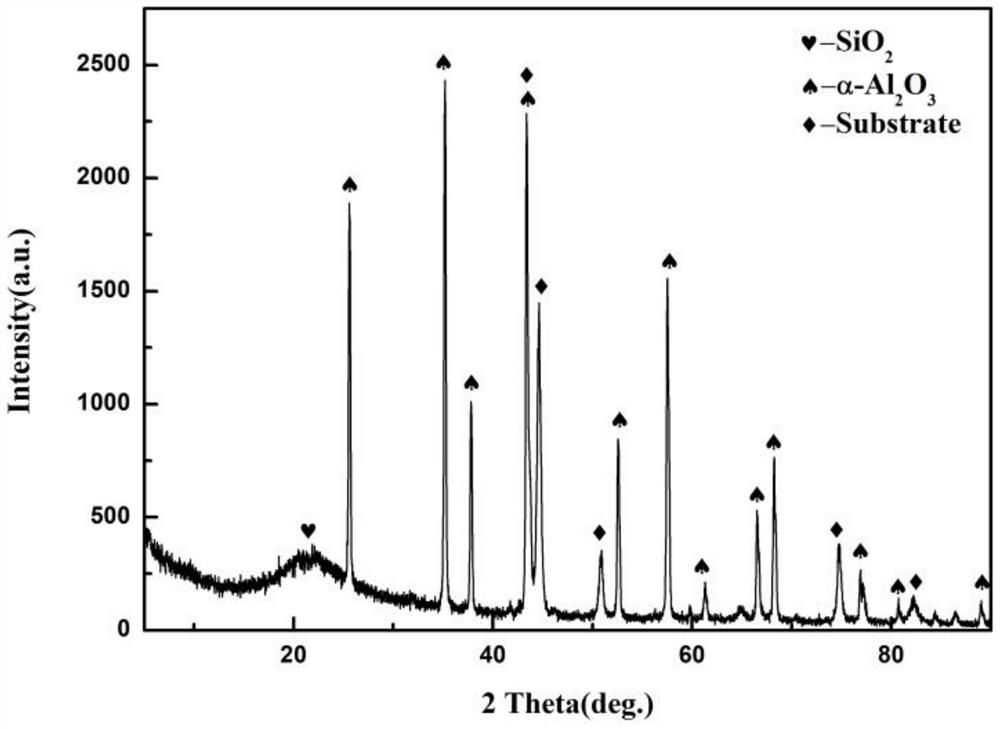

[0033] SiO with high bond strength in this example 2 / α-Al 2 O 3 The preparation method of ceramic composite coating comprises the following steps:

[0034] Step 1: Pretreatment of the substrate

[0035] The 316L stainless steel plate was used as the substrate, and the 25mm × 25mm × 2mm plate-shaped samples were prepared by wire-cutting. Then, the samples were polished with 120# and 240# metallographic sandpaper in turn, and then ultrasonically cleaned with alcohol and dried for later use.

[0036] Step 2: Preparation of Slurry

[0037] 99.99% pure α-Al 2 O 3 The powder and alkaline silica sol (JN-30) with a mass fraction of 30% were respectively weighed and placed in a beaker, and then polyethylene glycol (PEG) was added. Then, the slurry was sonicated at room temperature, and after the sonication was completed, a magnetic stirrer was used to stir the slurry uniformly.

[0038] Among them, α-Al 2 O 3 Powder particle size is 30nm, α-Al 2 O 3 The addition amount of p...

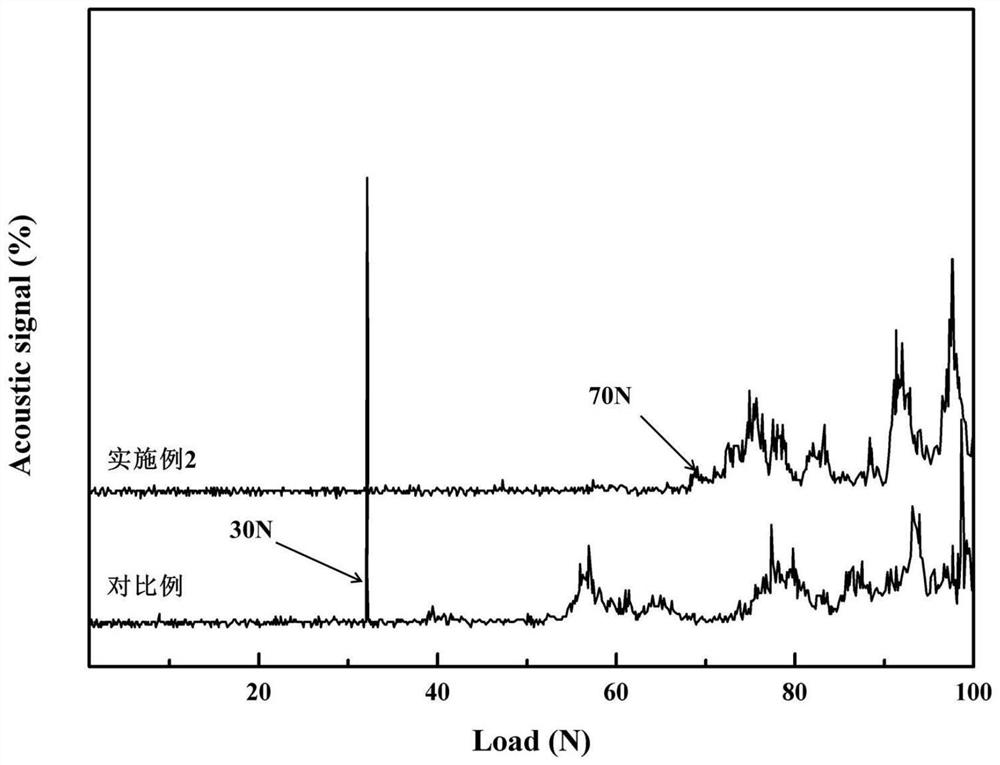

Embodiment 2

[0045] SiO with high bond strength in this example 2 / α-Al 2 O 3 The preparation method of ceramic composite coating comprises the following steps:

[0046] Step 1: Pretreatment of the substrate

[0047] A 316L stainless steel plate was used as the substrate, and a 25mm × 25mm × 2mm plate-like sample was prepared by wire-cutting. Then, the samples were polished with 120# and 240# metallographic sandpaper in turn, and then ultrasonically cleaned with alcohol and dried for later use.

[0048] Step 2: Preparation of Slurry

[0049] 99.99% pure α-Al 2 O 3 The powder and alkaline silica sol (JN-30) with a mass fraction of 30% were respectively weighed and placed in a beaker, and then polyethylene glycol (PEG) was added. Then the slurry was sonicated at room temperature, and after the ultrasonication was completed, the slurry was uniformly stirred with a magnetic stirrer, the rotational speed of the magnetic stirrer was 1000 rpm, and the stirring time was 10 h.

[0050] Among...

Embodiment 3

[0061] SiO with high bond strength in this example 2 / α-Al 2 O 3 The preparation method of ceramic composite coating comprises the following steps:

[0062] Step 1: Pretreatment of the substrate

[0063] The 316L stainless steel plate was used as the substrate, and the 25mm × 25mm × 2mm plate-shaped samples were prepared by wire-cutting. Then, the samples were polished with 120# and 240# metallographic sandpaper in turn, and then ultrasonically cleaned with alcohol and dried for later use.

[0064] Step 2: Preparation of Slurry

[0065] α-Al2O3 powder with a purity of 99.99% and alkaline silica sol (JN-30) with a mass fraction of 30% were respectively weighed and placed in a beaker, and then polyethylene glycol (PEG) was added. Then the slurry was sonicated at room temperature, and after the ultrasonication was completed, the slurry was uniformly stirred with a magnetic stirrer, the rotational speed of the magnetic stirrer was 1500 rpm, and the stirring time was 15 h.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com