Pasty diatom ooze and preparation method thereof

A technology of diatom mud and paste is applied in the field of decoration and decoration building materials, which can solve problems such as great harm to human health, and achieve the effects of preventing heat loss, large specific surface area, and health promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Step 1: Take the following raw materials in parts by weight: 80 kg of diatomite, 50 kg of titanium dioxide, 30 kg of chitosan, 20 kg of expanded perlite, 15 kg of methyl cellulose, 40 kg of sodium alginate, 10 kg of glycerin, and 180 kg of water;

[0065] Step 2: put diatomaceous earth, titanium dioxide, chitosan, expanded perlite, and methylcellulose into the reactor and stir at 800r / min for 2.5h to obtain diatom mud powder;

[0066] Step 3: Put sodium alginate into glycerin and stir to dissolve, then add water and continue stirring for 10 minutes to obtain a gelatinous liquid;

[0067] Step 4: Add the diatom mud powder obtained in step 2 to the colloidal liquid obtained in step 3, and stir at 700 r / min for 1 hour to obtain a diatom mud paste.

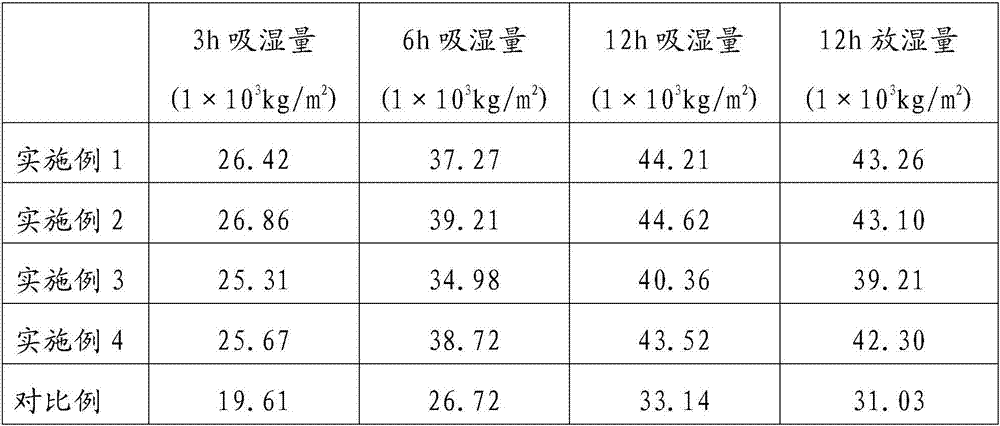

[0068] After the above paste diatom mud is colored with inorganic pigments, it is used to paint and decorate the interior wall, and its humidity control performance and formaldehyde adsorption performance are tested. The test r...

Embodiment 2

[0070] Step 1: Take the following raw materials in parts by weight: 50 kg of diatomite, 80 kg of titanium dioxide, 20 kg of chitosan, 30 kg of expanded perlite, 10 kg of methyl cellulose, 60 kg of sodium alginate, 20 kg of glycerin, and 150 kg of water;

[0071] Step 2: put diatomaceous earth, titanium dioxide, chitosan, expanded perlite, and methylcellulose into the reactor and stir at 1000r / min for 1.5h to obtain diatom mud powder;

[0072] Step 3: Put sodium alginate into glycerin and stir to dissolve, then add water and continue stirring for 10 minutes to obtain a gelatinous liquid;

[0073] Step 4: Add the diatom mud powder obtained in step 2 to the colloidal liquid obtained in step 3, and stir at 600 r / min for 1 hour to obtain a diatom mud paste.

[0074] After the above paste diatom mud is colored with inorganic pigments, it is used to paint and decorate the interior wall, and its humidity control performance and formaldehyde adsorption performance are tested. The test ...

Embodiment 3

[0076] Step 1: Take the following raw materials in parts by weight: 60 kg of diatomite, 60 kg of titanium dioxide, 25 kg of chitosan, 25 kg of expanded perlite, 12 kg of methyl cellulose, 50 kg of sodium alginate, 15 kg of glycerin, and 160 kg of water;

[0077] Step 2: Put diatomaceous earth, titanium dioxide, chitosan, expanded perlite, and methyl cellulose into the reactor and stir at 900r / min for 2 hours to obtain diatom mud powder;

[0078] Step 3: Put sodium alginate into glycerin and stir to dissolve, then add water and continue stirring for 10 minutes to obtain a gelatinous liquid;

[0079]Step 4: Add the diatom mud powder obtained in step 2 to the colloidal liquid obtained in step 3, and stir at 600 r / min for 2 hours to obtain a diatom mud paste.

[0080] After the above paste diatom mud is colored with inorganic pigments, it is used to paint and decorate the interior wall, and its humidity control performance and formaldehyde adsorption performance are tested. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com