Epoxy resin composition for packaging LED (Light Emitting Diode) display screen

An LED display, epoxy resin technology, applied in electrical components, circuits, electrical solid devices, etc., can solve the problems of increased polarity of the colloid surface, high temperature yellowing, dust adsorption, etc., to improve contrast and grayscale, The effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

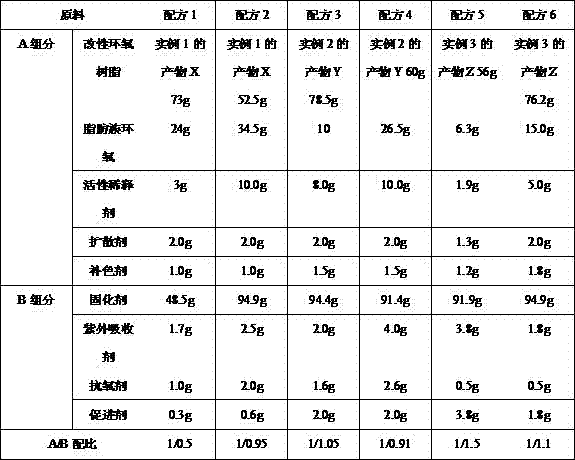

Embodiment 1

[0019] Example 1: First weigh 208g of tetraethoxysilane and 100g of ethanol in sequence, mix them evenly, and pour them into a 1000ml four-necked flask with cooling, stirring and heating devices; then slowly add 108g of PH =3 hydrochloric acid aqueous solution, continue to react for 1 hour after the dropwise addition; then start to drop 64.8g of hexamethyldisiloxane, after the dropwise addition, raise the temperature to 50°C for 4h, 80°C for 2h; then add 120g of toluene and let stand , layered, washed, and decompressed to obtain a colorless and transparent silicone resin a; finally, take out 10.0g of the above-mentioned silicone resin a and 190.0g of epoxy resin 828E, add them to a 500ml reaction bottle in turn, and mix them in 0.4g of catalyst Under the action of dibutyltin dilaurate, react in vacuum at 100°C for 3 hours to obtain a colorless and transparent modified epoxy resin X.

Embodiment 2

[0020] Example 2: first weigh 145.6g tetraethoxysilane, 40.8g trimethyltrimethoxysilane and 100g ethanol in sequence, mix them evenly, and pour them into a 1000ml four-necked flask with cooling, stirring and heating devices ; Then slowly add 100g of hydrochloric acid aqueous solution with pH=3 dropwise at 25°C, and continue to react for 1h after the dropwise addition; then start to add 97.2g of hexamethyldisiloxane dropwise, and after the dropwise addition, raise the temperature to 50°C for 4h, React at 80°C for 2 hours; finally add 150g of toluene to stand still, separate layers, wash until neutral, and distill under reduced pressure to obtain a colorless and transparent silicone resin b; finally, take out 30.0g of the above-mentioned silicone resin b and 270g of epoxy resin 828E, Sequentially add to a 500ml reaction bottle, and under the action of 0.6g of dibutyltin dilaurate as a catalyst, react in vacuum at 100°C for 3h to obtain a colorless and transparent modified epoxy r...

Embodiment 3

[0021] Embodiment 3: first weigh 208g tetraethoxysilane, 40.8g trimethyltrimethoxysilane, 10.6g trifluoropropylmethyltrisiloxane and 100g ethanol in sequence, mix them uniformly, pour into Into a 500ml four-neck flask with cooling, stirring and heating equipment; then slowly add 100g of PH=3 hydrochloric acid aqueous solution dropwise at 25°C, and continue the reaction for 1h after the dropwise addition; then start to dropwise add 97.2g of hexamethyldisiloxane , after the dropwise addition, the temperature was raised to 50°C for 4 hours, and 80°C for 2 hours; finally, 120g of toluene was added to stand, separated, washed until neutral, and distilled under reduced pressure to obtain a colorless and transparent silicone resin c; finally, 40.0g was taken out Add the above silicone resin c and 160g epoxy resin 828E into a 500ml reaction bottle in sequence, and react in vacuum at 100°C for 3 hours under the action of 0.4g of dibutyltin dilaurate as a catalyst to obtain a colorless a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com