Laboratory urea hydrolysis reaction device

A urea hydrolysis and reaction device technology, which is applied in the preparation/separation of ammonia compounds, ammonia, inorganic chemistry, etc., to achieve the effects of simple structure, large heating surface area, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the embodiments do not limit the present invention.

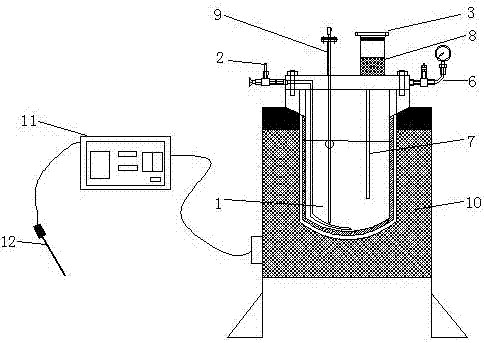

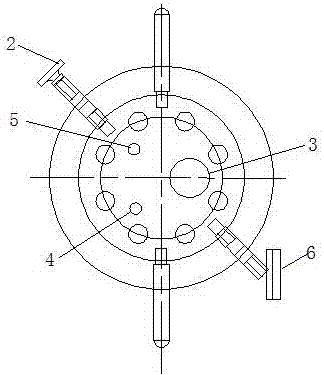

[0018] combine figure 1 with figure 2 ;

[0019] A laboratory urea hydrolysis reaction device, characterized in that it includes a hydrolysis reactor (1), the bottom and surroundings of the hydrolysis reactor are wrapped by a heating furnace (10), and the heating furnace (10) is an electric heating method, The heating furnace (10) fits with the hydrolysis reactor (1), and the heating furnace is supported by legs. The heating furnace (10) is connected to a controller (11) with a temperature sensor (12) through wires, and the controller (11) uses It is used to control the temperature and heating voltage in the hydrolysis reactor (1); the upper part of the hydrolysis reactor (1) is provided with a urea solution inlet (2) and a gas phase product outlet (3). The heat required for the urea hydrolysis reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com