Fadeless plating processing technology

A processing technology and coating technology, which is applied in the field of non-fading coating processing technology, can solve the problems of easy wear and fading of the coating on the surface of jewelry, and achieve the effects of electro-gold technology optimization, anti-fouling ability improvement, and good anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: electro-gold on the surface of jewelry

[0043] When the electroplating layer on the surface of jewelry is a gold-plated layer, the specific process of electro-gold treatment:

[0044] (i) Surface polishing to remove sand holes and file marks on the surface of the workpiece.

[0045] Surface polishing is carried out according to the conventional steps in this field, which can include frying and polishing, polishing and polishing the surface of the workpiece with supporting tools, so that the rough surface of the workpiece becomes smooth and shiny, so as to carry out timely and effective repair; wax removal, repair, Make up for the defects, defects, damage, etc. of the workpiece; glue (oil); sandblasting; oil (nail polish); glue removal, and finally electrolytic polishing.

[0046] (ii) Ultrasonic cleaning; ultrasonic degreasing uses the mechanical force of ultrasonic oscillation to generate tens of thousands of small bubbles in the degreasing solution. , T...

Embodiment 2

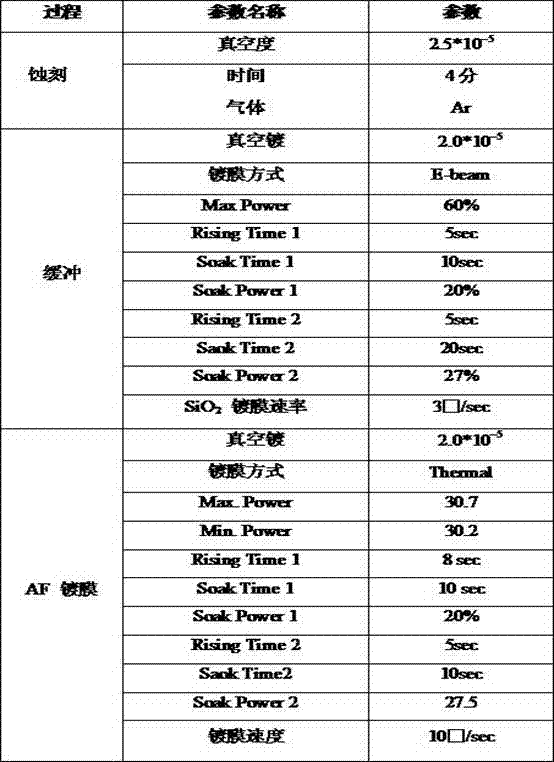

[0056] Embodiment 2: the surface coating processing of jewelry after gold-plated treatment

[0057] The specific treatment process includes: spraying nano-coating and optical coating.

[0058] Step (1): Spray nano-coating, the specific process is as follows:

[0059] Need to use special jigs, select the appropriate jigs according to the jewelry that needs to be processed, first install the jigs on the production line, and then wear dust-free gloves to install the products to the production line along with the line. Note that the operator must wear medical gloves when installing the products. , to prevent fingerprints from directly touching the product with hands. Production lines conventionally used in the field for spraying nano-coatings are applicable as long as they can meet the process requirements.

[0060] (1-1) Electrostatic dust removal: Adjust the electrostatic air gun, aim at jewelry products, and remove dust from the products at a distance of 10 cm.

[0061] El...

Embodiment 3

[0081] Embodiment 3: the surface coating processing of jewelry after electro-gold treatment

[0082] The specific details and precautions of the experimental process are the same as in Example 2.

[0083] Step (1): Spray nano-coating

[0084] Select the appropriate jig according to the jewelry that needs to be processed, first install the jig on the production line, and then wear dust-free gloves to install the product to the production line along with the line. Note that the operator must wear medical gloves when installing the product to prevent direct contact with hands Product has fingerprints.

[0085] (1-1) Electrostatic dust removal: Adjust the electrostatic air gun, aim at jewelry products, and remove dust from the products at a distance of 15 cm.

[0086] (1-2) Plasma treatment: The distance between the plasma torch head and the jewelry product is 3mm; the treatment is carried out until the water drop angle is ≤10°.

[0087] (1-3) Spraying: Use multiple spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com