Preparation method of grinding wheel with discretely reinforced hub electroplated with super hard abrasive

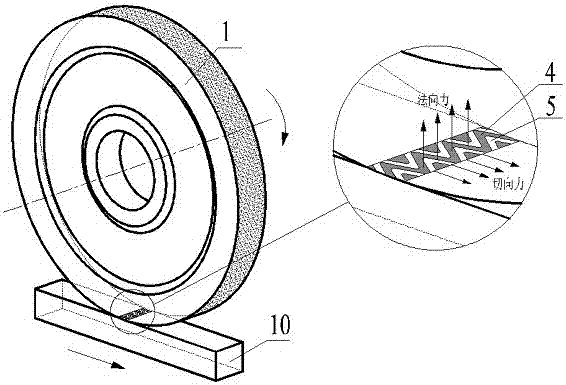

A super-hard abrasive and wheel-strengthening technology, applied in grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of increased grinding wheel manufacturing cost, complex material ratio, difficult process control, etc., to improve the support capacity , Improve the effect of resisting normal grinding force and improve the effect of anti-peeling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings.

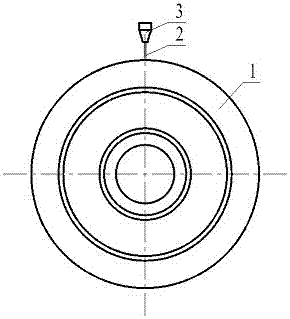

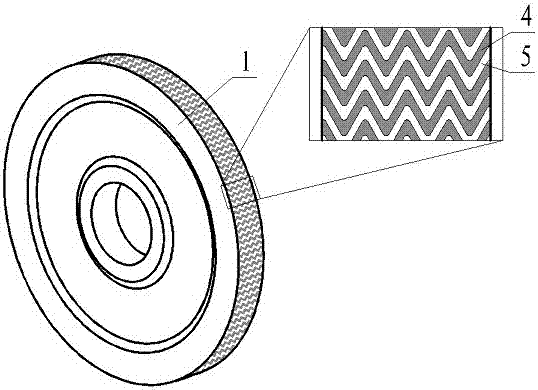

[0028] Step 1. Select No. 45 steel as the material of the grinding wheel hub 1, and finish machining a wheel with a diameter of Φ150 mm, a thickness of 10 mm, a hole diameter of Φ32 mm, a roughness of the outer circumference of 0.1-0.4 μm, and a cylindricity of 0.002-0.005 mm. Grinding wheel hub 1. Carry out degreasing and derusting treatment to the surface of the emery wheel hub 1 again, and dry it with hot air after completion.

[0029]Step 2. Install the grinding wheel hub 1 on the machine tool, select the nozzle 3 with a diameter of Φ0.3 mm, fix the quenching gun in the direction perpendicular to the axis of the grinding wheel hub 1, adjust the distance between the nozzle 3 and the grinding wheel hub 1 to 5 mm, and turn on For the power supply of the plasma arc quenching generator, set the operating voltage of the plasma control equipment to 42...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com