High-performance piezoelectric ceramic material, preparation method of high-performance piezoelectric ceramic material and piezoelectric ceramic material product

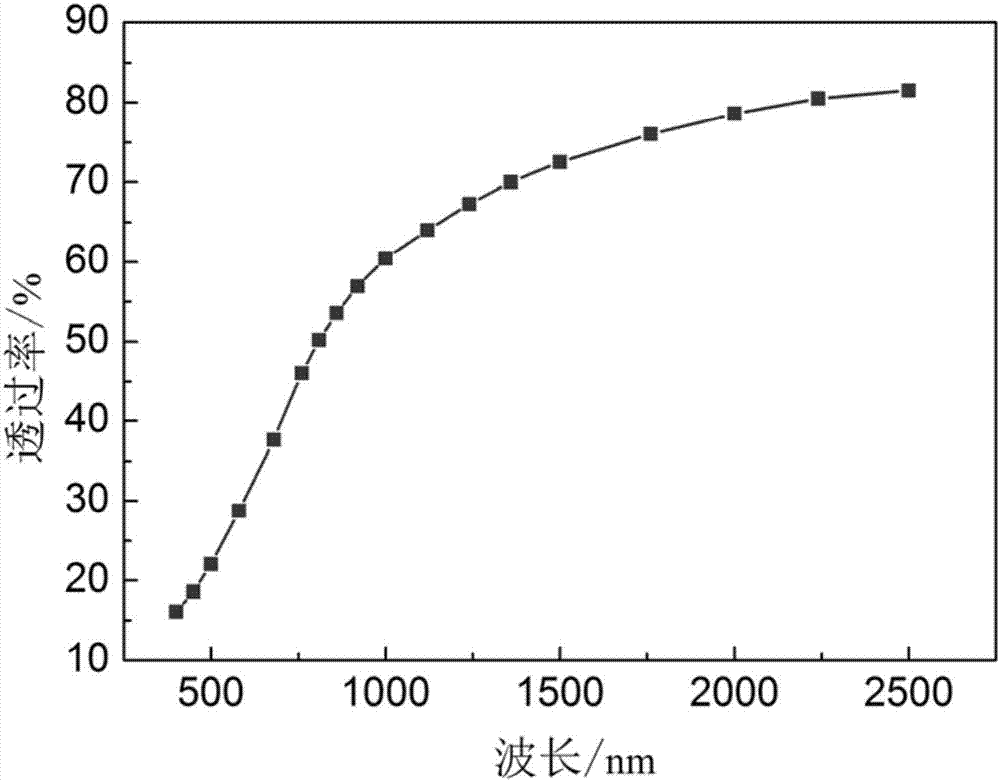

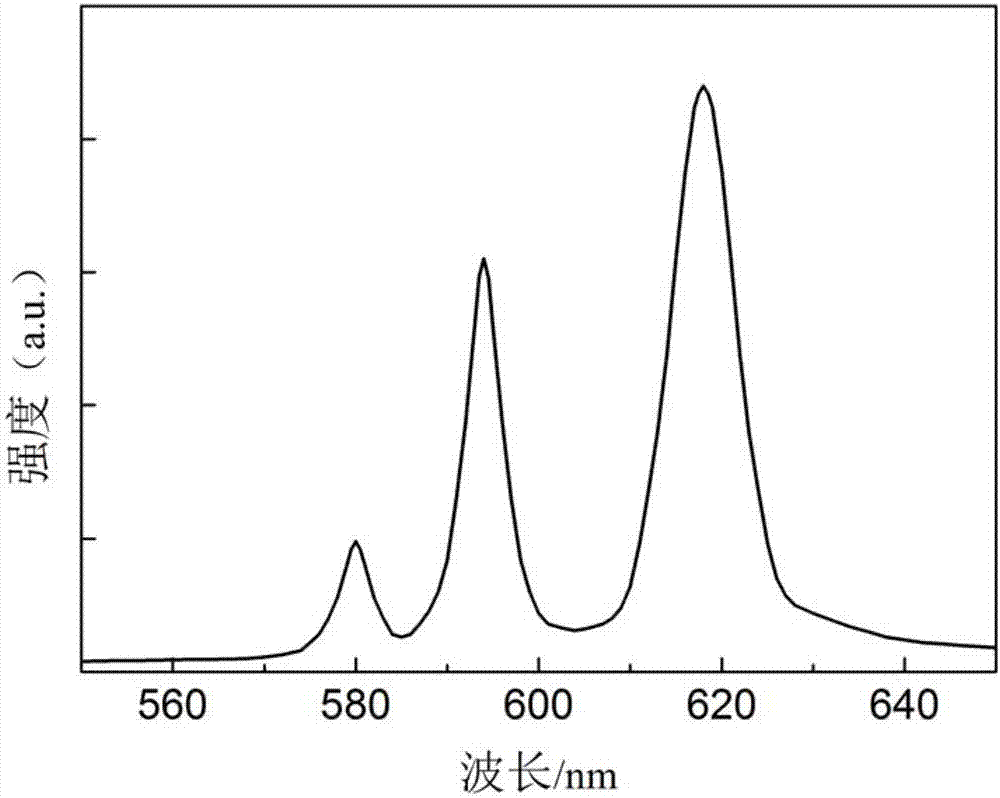

A piezoelectric ceramic and high-performance technology, which is applied in the field of piezoelectric ceramic material products and high-performance piezoelectric ceramic materials, can solve the problems of single and general performance, and achieve high luminescence, simple operation method, and high light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a high-performance piezoelectric ceramic material, comprising the steps of:

[0026] S1, according to the ratio of the amount of substances of sodium element, potassium element, lithium element, calcium element, rare earth element, niobium element, tin element and oxygen element is (1-x-y-z-w):z:y:x:w: (1- x):x:3, where x=0.02~0.06, y=0.02~0.08, z=0.35~0.50, w=0.001~0.004, the sodium carbonate, potassium carbonate, lithium carbonate, calcium carbonate, rare earth to be used for calculation The mass fractions of oxides, niobium pentoxide and tin oxide were weighed according to the obtained mass fractions of sodium carbonate, potassium carbonate, lithium carbonate, calcium carbonate, rare earth oxides, niobium pentoxide and tin oxide for subsequent use.

[0027] The mass of the raw materials to be used is calculated according to the proportions of the above-mentioned elements, and the raw materials are accurately weighed according to the calculated ...

Embodiment 1

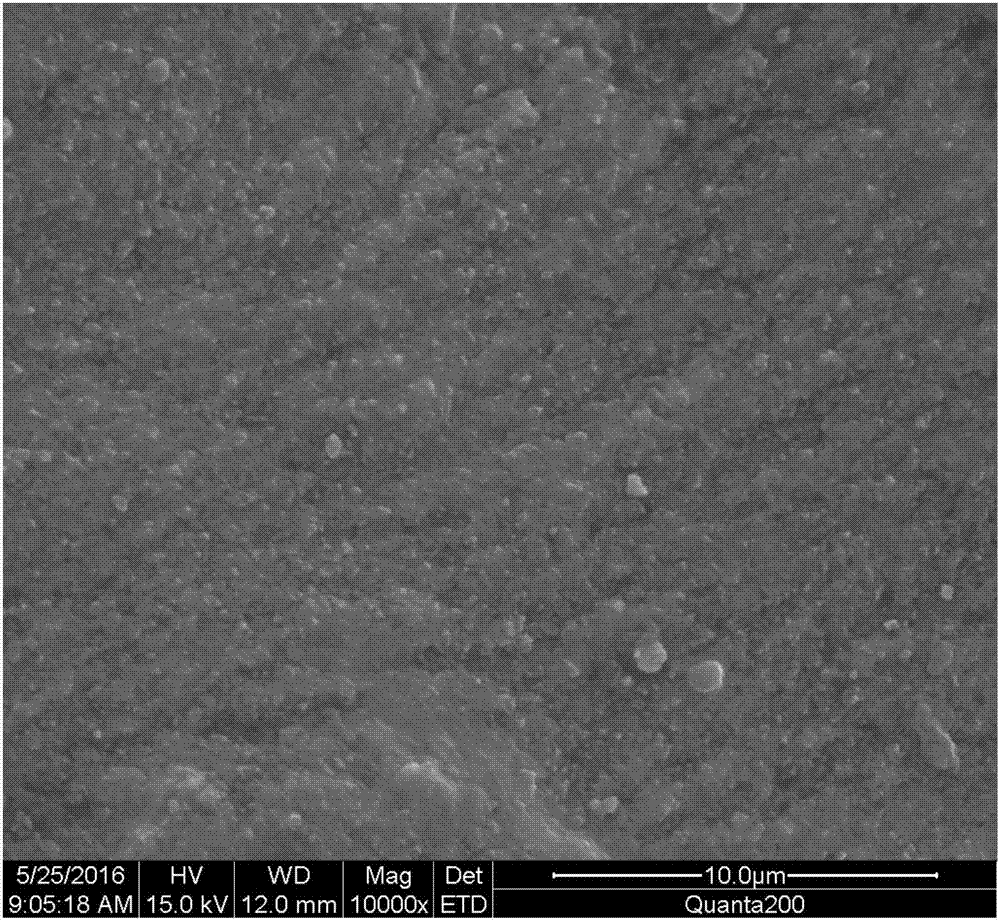

[0047] This embodiment provides a method for preparing a high-performance piezoelectric ceramic material and the prepared high-performance piezoelectric ceramic material. According to the ratio of the amount of sodium element, potassium element, lithium element, calcium element, erbium element, niobium element, tin element and oxygen element, it is (1-x-y-z-w):z:y:x:w:(1-x) :x:3, where x=0.02, y=0.08, z=0.35, w=0.004, the sodium carbonate, potassium carbonate, lithium carbonate, calcium carbonate, rare earth oxide, niobium pentoxide and tin oxide to be used for calculation According to the mass fraction obtained, weigh sodium carbonate, potassium carbonate, lithium carbonate, calcium carbonate, erbium oxide, niobium pentoxide and tin oxide for subsequent use; mix the obtained raw materials and grind until the particle size is less than or When the thickness is equal to 5 μm, calcining is carried out, the calcining temperature is 700° C., and the calcining time is 28 minutes. ...

Embodiment 2

[0049] This embodiment provides a method for preparing a high-performance piezoelectric ceramic material and the prepared high-performance piezoelectric ceramic material. According to the ratio of the amount of sodium element, potassium element, lithium element, calcium element, europium element, niobium element, tin element and oxygen element, it is (1-x-y-z-w):z:y:x:w:(1-x) :x:3, where x=0.04, y=0.06, z=0.45, w=0.003, the sodium carbonate, potassium carbonate, lithium carbonate, calcium carbonate, rare earth oxide, niobium pentoxide and tin oxide to be used for calculation According to the mass fraction obtained, weigh sodium carbonate, potassium carbonate, lithium carbonate, calcium carbonate, europium oxide, niobium pentoxide and tin oxide for future use; mix the obtained raw materials and grind until the particle size is less than or When the thickness is equal to 5 μm, calcining is carried out, the calcining temperature is 950° C., and the calcining time is 60 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com