Reinforced flame-retarding PA6/POK (Polyamide 6/Polyketone) alloy material and preparation method thereof

A technology of alloy materials and flame retardants, applied in the field of reinforced flame retardant PA6/POK alloy materials and their preparation, can solve the problem of low molding efficiency of nylon 6 reinforced flame retardant materials, high wet volume resistivity, and the amount of flame retardants used Large and other problems, to achieve the effect of increasing wet volume resistivity, improving environmental protection performance, and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

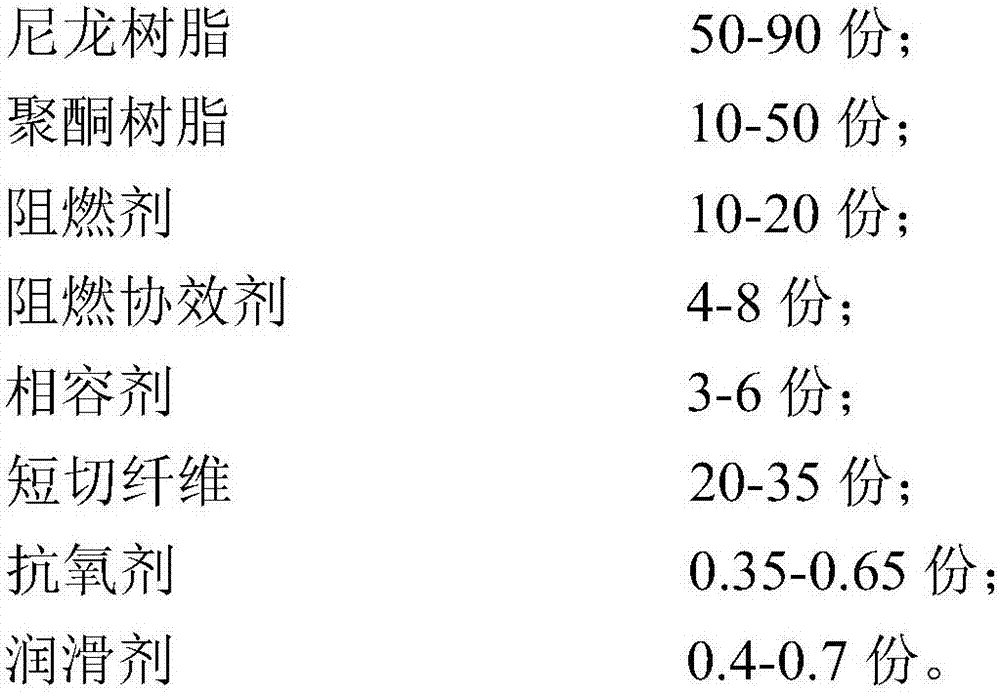

[0029] A kind of reinforced flame-retardant PA6 / POK alloy material, comprising by weight:

[0030]

[0031] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 30 parts of chopped fibers pass through the side feeding Add by way, keep the vacuum open, the temperature of each temperature zone of the extruder is 210°C (zone 1), 230°C (zone 2), 220°C (zone 3), 210°C (zone 4), 175°C (zone 4) , 175°C (zone five), 180°C (zone six), 190°C (zone seven), 210°C (zone eight), and 235°C (head).

[0032] The vertical combustion performance of the above-mentioned composite material is 1.6mm V-0, the water absorption rate is 0.406%, and the wet volume resistivity is 3.8×10 14 Ω cm, the mechanical properties of the material are: tensile strength 150.5MPa, elongation at break 6.1%, bending strength 225.5MPa, notched impact strength 14.1kJ / m 2 , u...

Embodiment 2

[0034] The present embodiment differs from Example 1 in that: first take the following materials in parts by weight:

[0035]

[0036] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 30 parts of chopped fibers pass through the side feeding Add by way, keep the vacuum open, the temperature of each temperature zone of the extruder is 210°C (zone 1), 230°C (zone 2), 220°C (zone 3), 210°C (zone 4), 175°C (zone 4) , 175°C (zone five), 180°C (zone six), 190°C (zone seven), 210°C (zone eight), and 235°C (head).

[0037] The vertical combustion performance of the composite material obtained above is 1.6mm V-0, the water absorption rate is 0.428%, and the wet volume resistivity is 4.7×10 14 Ω cm, the mechanical properties of the material are: tensile strength 151.6MPa, elongation at break 6.3%, bending strength 227.5MPa, notched impac...

Embodiment 3

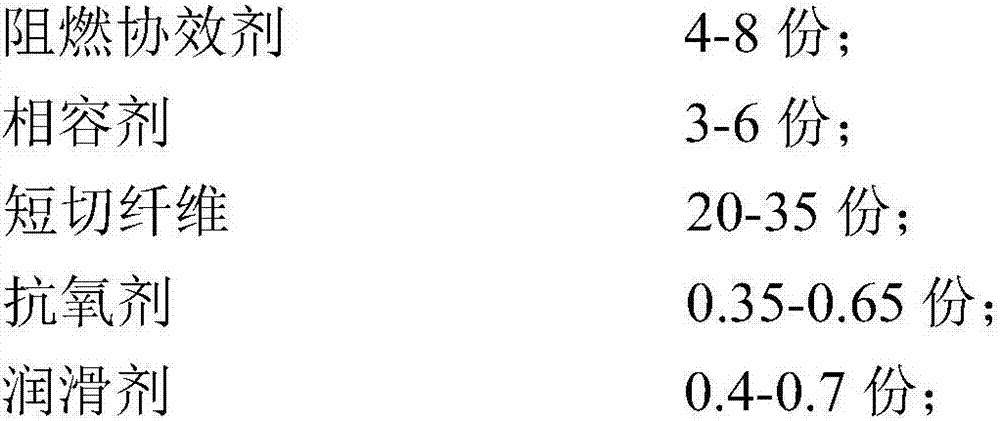

[0039] The present embodiment differs from Example 1 in that: first take the following materials in parts by weight:

[0040]

[0041] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 30 parts of chopped fibers pass through the side feeding Add by way, keep the vacuum open, the temperature of each temperature zone of the extruder is 210°C (zone 1), 230°C (zone 2), 220°C (zone 3), 210°C (zone 4), 175°C (zone 4) , 175°C (zone five), 180°C (zone six), 190°C (zone seven), 210°C (zone eight), and 235°C (head).

[0042] The vertical combustion performance of the composite material obtained above is 1.6mm V-0, the water absorption rate is 0.386%, and the wet volume resistivity is 4.6×10 14 Ω cm, the mechanical properties of the material are: tensile strength 152.5MPa, elongation at break 5.1%, bending strength 228.5MPa, notched impac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com