Thermosetting resin composition

A resin composition, thermosetting technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of accelerating the reactivity of the resin system, affecting the gel time of the resin composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

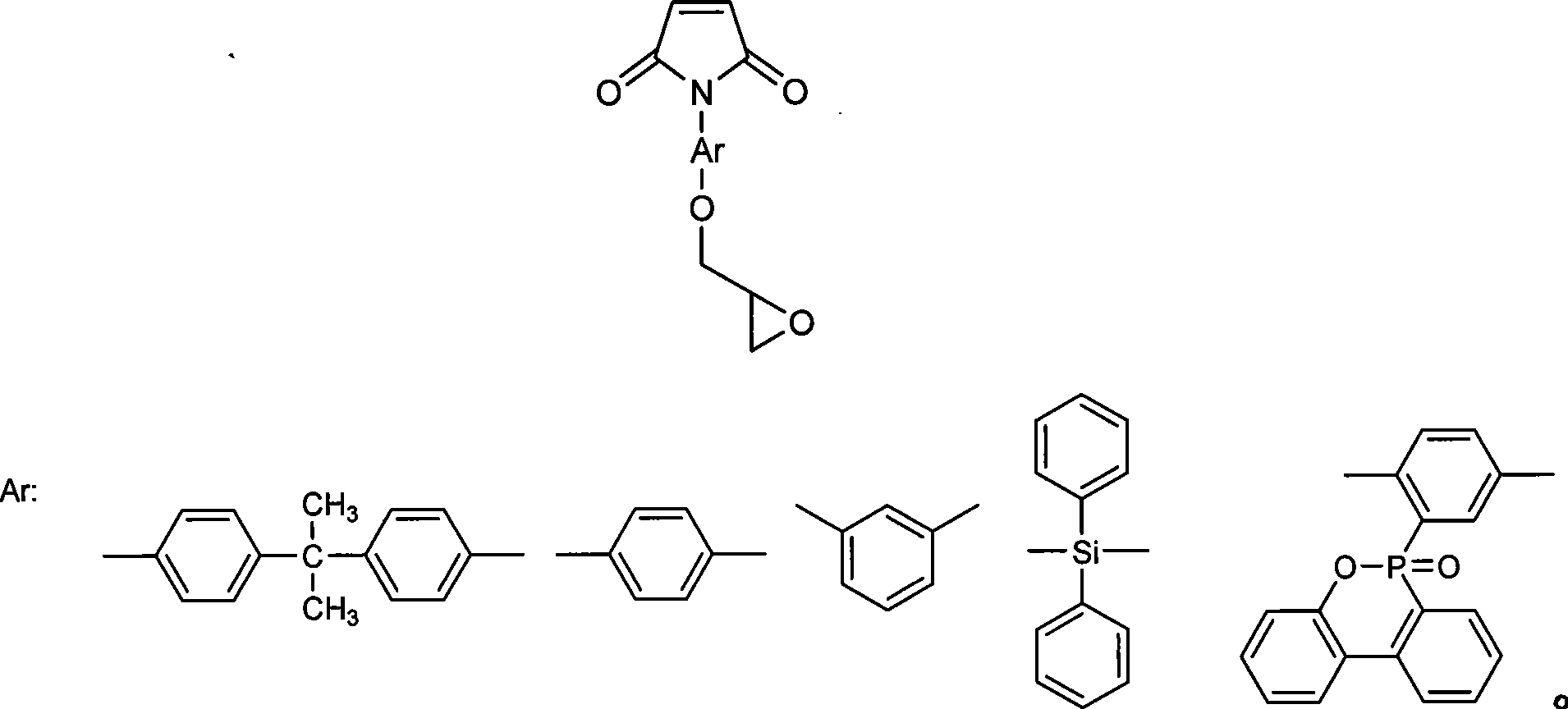

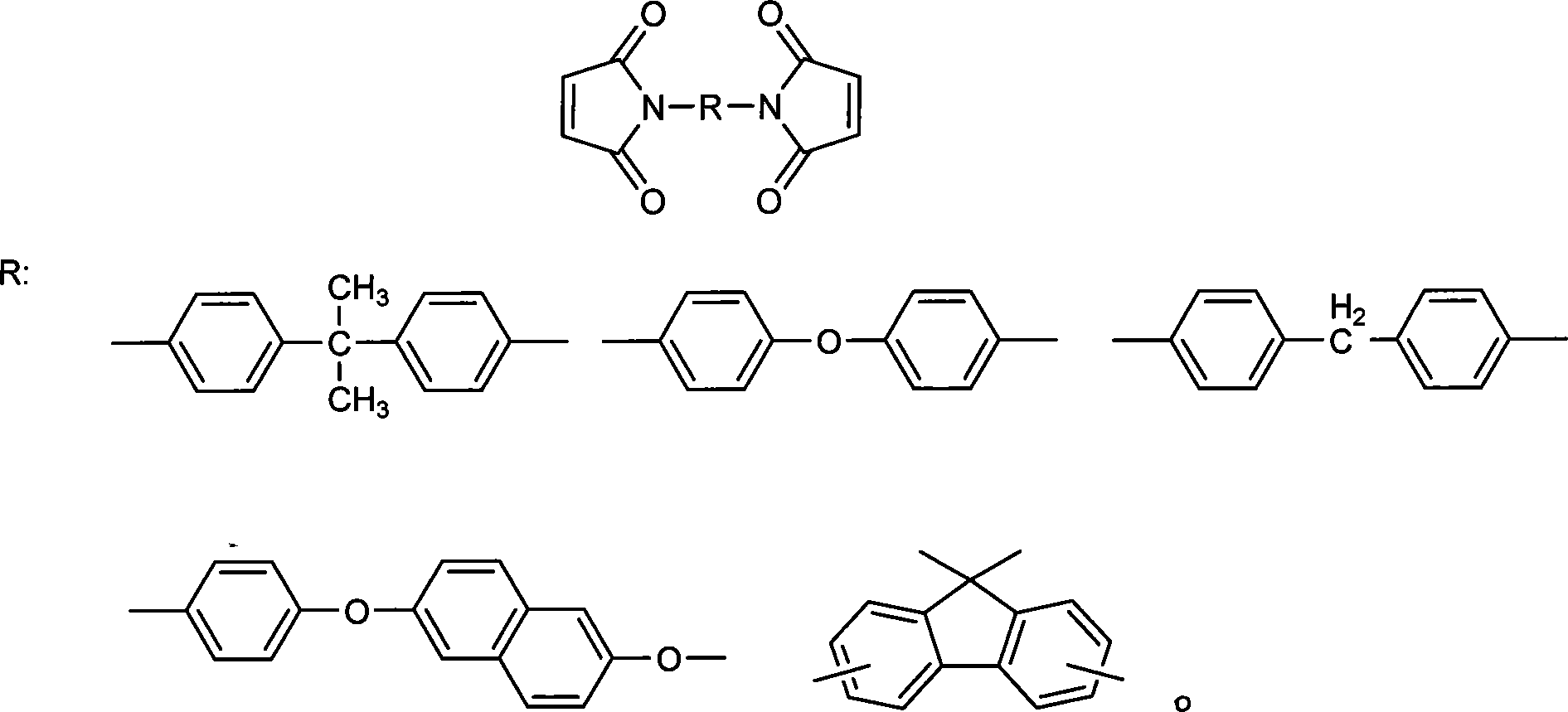

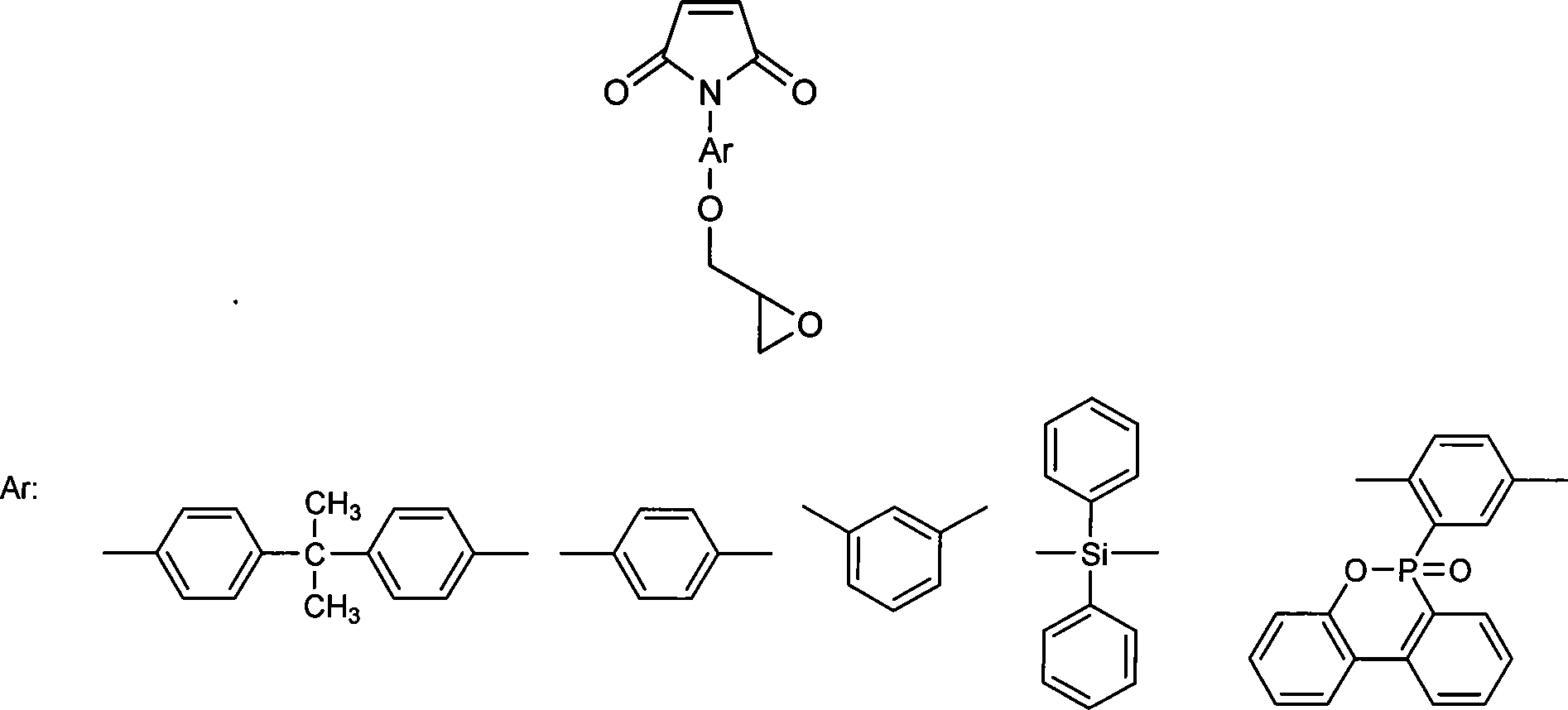

Image

Examples

Embodiment 1

[0084] The preparation of embodiment 1MPGE / BMI prepolymer (hereinafter referred to as prepolymer I) (see attached table 2):

[0085] 21.9 grams of MPGE (0.0886 equiv.), 31.7 grams of 4,4'-diaminodiphenylmethane type bismaleimide (0.0885 equiv.) and 104.0 grams of butanone (solvent) were added to a reflux condenser equipped with tube, stirrer and thermometer in a three-neck round bottom flask, N 2 Stir under the atmosphere and heat up to 80°C, slowly add 0.073 g of azobisisobutylcyanide (free radical initiator) twice, reflux for 20 minutes, then add 0.048 g of hydroquinone (polymerization inhibitor), and cool to room temperature . A solution of prepolymer I with a solids content of 34.0% was obtained.

Embodiment 2

[0086] The preparation of embodiment 2MPGE / BMI prepolymer (hereinafter referred to as prepolymer II) (see attached table 2):

[0087] Each reactant and method are with embodiment 1, but the consumption of each reactant becomes respectively: 43.8 gram MPGE (0.177equiv.), 31.8 gram 4,4'-diaminodiphenylmethane type bismaleimide (0.0885 equiv.), methyl ethyl ketone 147.1 grams, azobisisobutyronitrile 0.108 grams, hydroquinone 0.070 grams. A prepolymer II solution with a solids content of 34.0% was obtained.

[0088] The preparation of table 2MPGE / BMI prepolymer

[0089]

[0090] The synthetic reaction equation of prepolymer I:

[0091]

[0092] Copolymerization product in prepolymer I

[0093] The synthesis reaction equation of prepolymer II:

[0094]

[0095] Copolymerization product in prepolymer II

Embodiment 3 to Embodiment 14 and comparative example 1 to comparative example 3

[0096] Embodiment 3 to embodiment 14 and comparative example 1 to comparative example 3 thermosetting resin compositions:

[0097] The formula of each embodiment is shown in attached table 3 and attached table 4.

[0098] The resin composition formula of table 3 embodiment 3-10

[0099]

[0100] The resin composition prescription of table 4 embodiment 11-14 and comparative example 1-3

[0101]

[0102] In prepolymer I and prepolymer II formula, the molar ratio (hereinafter referred to as MR) of BMI and MPGE is respectively 1: 1 and 1: 2, and in embodiment 3 to embodiment 10, filler ratio is 30% or 60% (mainly in order to investigate the impact of different fillers and their contents on the performance of the substrate); in the formulas of Example 11 and Example 12, the proportions of fillers are respectively 30% and 50%; in the formulas of Example 13 and Example 14, the proportions of fillers are respectively Be 30% and 50%, but the content of bromine in the system has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com