Method for preparing bismuth-enriched bismuth oxybromide photocatalyst

A bismuth-rich bismuth oxybromide and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of weak photocatalyst performance and high cost, and achieve the effects of easy operation, remarkable effect and low solvent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

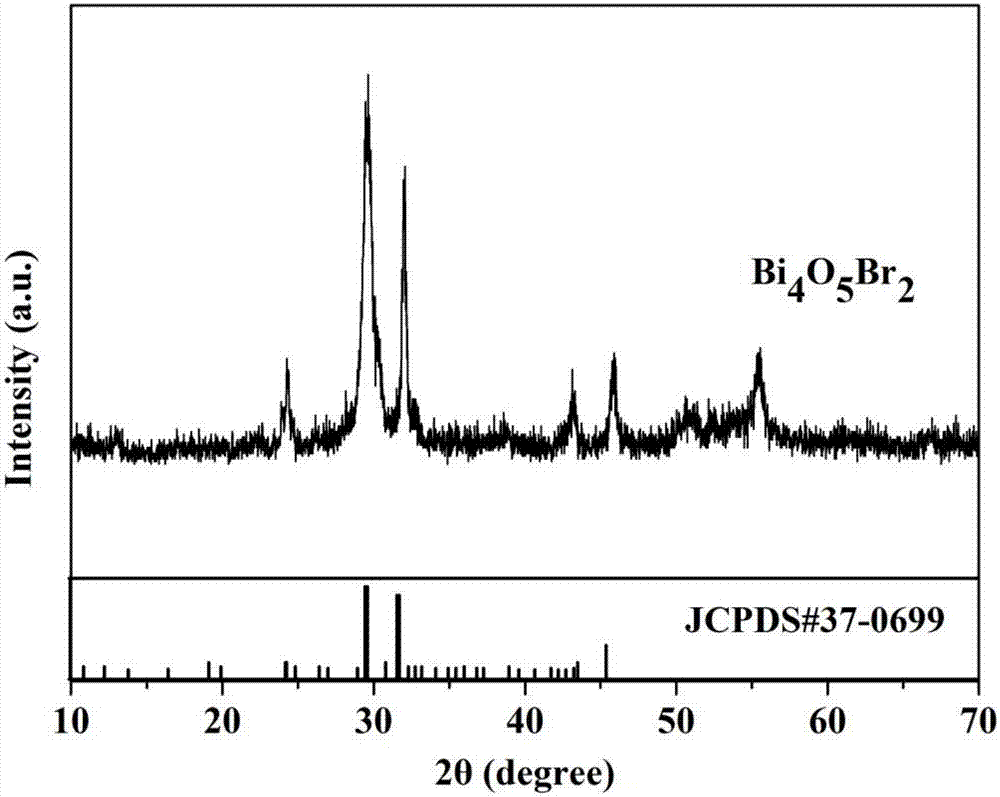

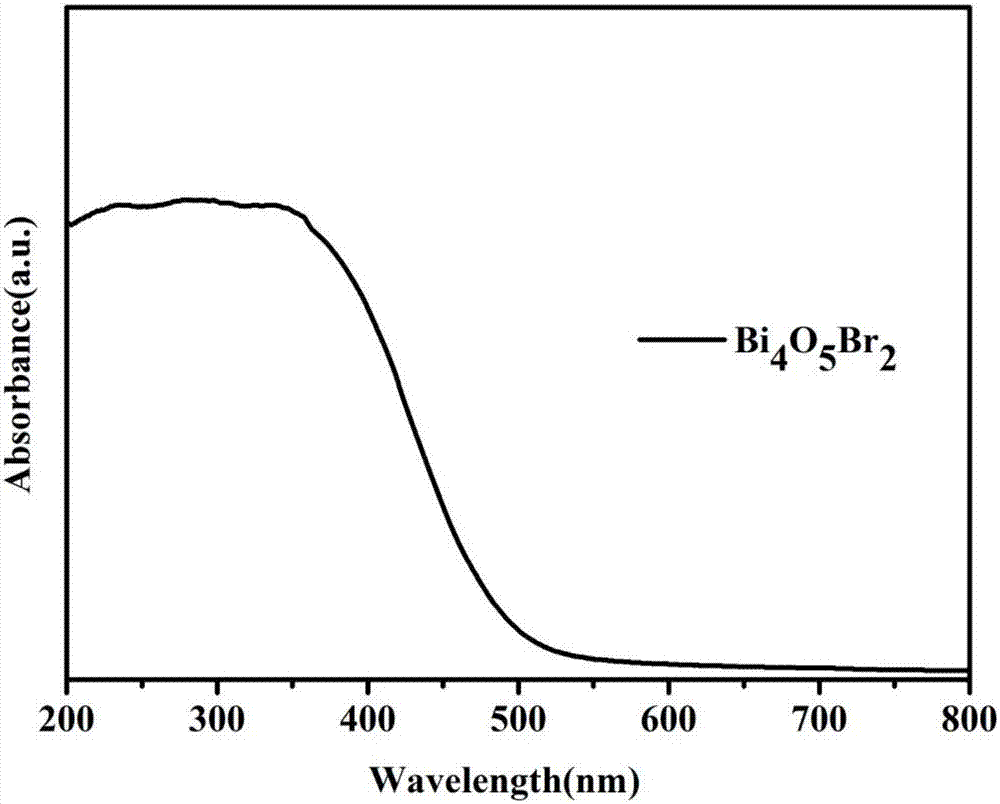

[0014] The preparation method of a bismuth-rich bismuth oxybromide photocatalyst of the present invention is characterized in that a certain amount of polymer is added to a mixed solvent of a specific ratio, the pH value of the mixed solvent is adjusted, and bismuth-rich is synthesized in one step by a solvothermal method Bismuth oxybromide Bi 4 o 5 Br 2 Photocatalyst, the prepared bismuth-rich bismuth oxybromide Bi 4 o 5 Br 2 It has efficient visible light catalytic performance, and the specific steps are:

[0015] Measure glycerol and deionized water with a total volume of 30mL into a beaker at a ratio of 1:1 to 1:5, accurately weigh 1.5mmol of bismuth nitrate pentahydrate, add it, stir until clear and transparent, and then accurately weigh Add 1.5mmol of bromine source to the above solution, continue to stir for 0.5~1h, at this time, accurately weigh 0.1~0.5g of polymer, add it to the above solution, and immediately add -1 Sodium hydroxide solution to adjust the pH va...

Embodiment 1

[0017] Implementation example 1: a kind of preparation method of bismuth-rich bismuth oxybromide photocatalyst of the present invention comprises the following steps:

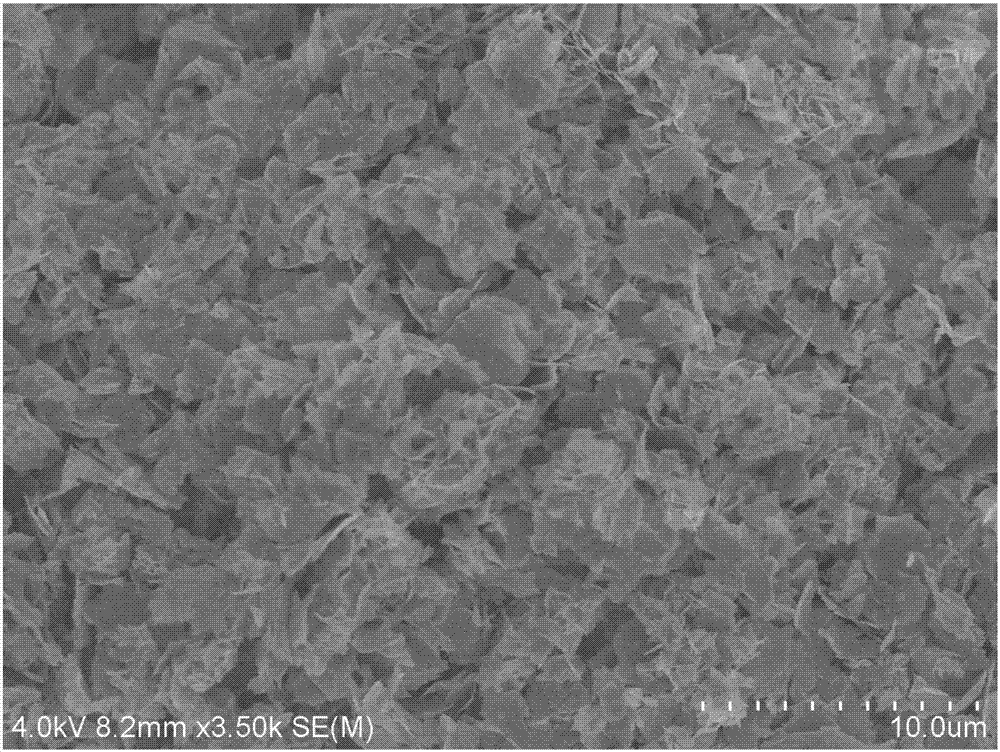

[0018] Measure 15 mL of glycerol and deionized water with a total volume of 30 mL into a beaker at a ratio of 1:1. Under magnetic stirring, accurately weigh 1.5 mmol of bismuth nitrate pentahydrate and add it, stir until it is clear, and then Accurately weighed 1.5mmol of cetyltrimethylammonium bromide was added to the above solution, and continued to stir for 30min. At this time, accurately weighed 0.1g of polyethylene glycol (PEG10000) was added to the above solution, and immediately used 1mol L -1 Adjust the pH value of the above solution to 11, stir until a uniform white suspension is formed, pour the solution into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, and react at 140°C for 24h. The obtained product was centrifuged, first washed with hot water to remove the residual organic ...

Embodiment 2

[0020] Implementation example 2: a kind of preparation method of bismuth-rich bismuth oxybromide photocatalyst of the present invention comprises the following steps:

[0021]Measure 5mL and 25mL of glycerol and deionized water with a total volume of 30mL into a beaker at a ratio of 1:5, and accurately weigh 1.5mmol of bismuth nitrate pentahydrate into the beaker under magnetic stirring, and stir until clear and transparent , then accurately weigh 1.5mmol of cetyltrimethylammonium bromide and join in the above solution, continue to stir for 30min, now accurately weigh 0.3g of polyethylene glycol (PEG2000) and join in the above solution, and Immediately use 1mol·L -1 Adjust the pH value of the above solution to 10, stir until a uniform white suspension is formed, pour the solution into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, and react at 140°C for 24h, The obtained product was centrifuged, first washed with hot water to remove the residual organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com