First-class returning-water quality percolating and purifying device for farmland

A purification device and farmland drainage technology, which is applied in the field of farmland non-point source pollution control, to achieve the effects of convenient replacement and renewal, low infrastructure cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the nano-composite material 6 is preferably dipping-pulling method, the nano-photocatalyst is preferably nano-titanium dioxide, and the carrier material can be porous ceramsite, porous glass spheres, glass fibers, etc., and the preparation steps of the nano-composite material 6 include:

[0031] (1) Preparation of photocatalyst sol by sol-gel method: the method is the same as that of nano-purification mesh 4, and will not be repeated here.

[0032] (2) Nanophotocatalyst-carrier loading, specifically, use crucible tongs or other tools that can play a supporting role to fix the filter with carrier material, and immerse it in anatase nano-TiO 2 After 5 minutes in the load solution, lift the surface of the liquid to stand for 15 minutes, repeat 4 to 5 times, and then rinse with pure water for 10 minutes to remove the anatase nano-TiO that is not tightly attached. 2 ; Dry at room temperature for 24 hours and then roast at high temperature (the tempe...

Embodiment

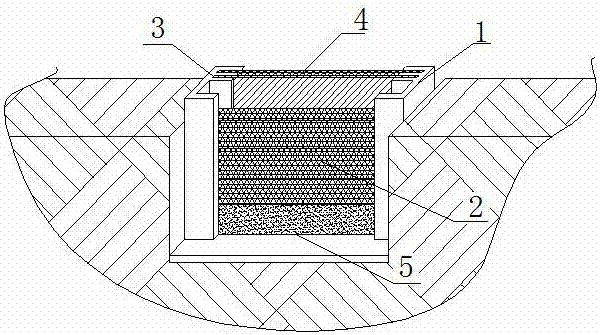

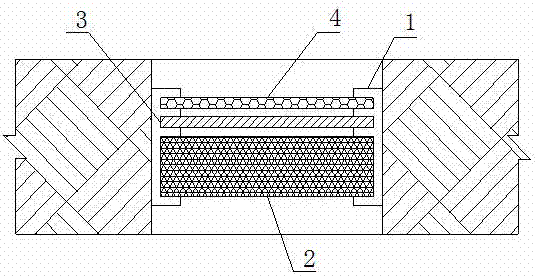

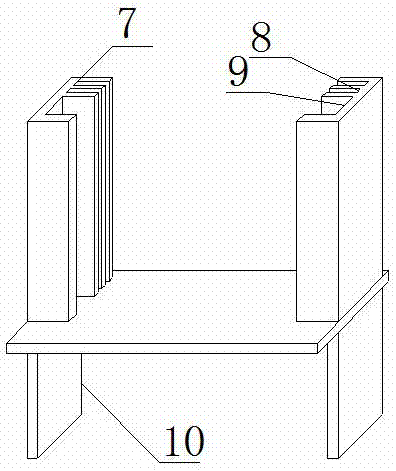

[0039] A filter and purification device for first-stage backwater in farmland, the structure of which includes a fixed bracket 1, a filter purification box 2, a drainage baffle 3, a nano-purification net 4, a water-blocking block 5, a nano-composite material 6, and a fixed bottom plate 10; Among them, the fixed bracket 1 is fixedly installed at the drainage outlet of the farmland, and there are three rows of grooves corresponding to the two sides of the bracket, which are respectively the installation groove 7 of the purification net, the installation groove 8 of the baffle and the installation groove 9 of the purification box, and correspondingly install the nano purification net in turn. 4. Drainage baffle 3 and percolation purification box 2. When installing, ensure that the installation tank 7 of the purification net is on the side of the farmland drainage water; during the non-drainage period of the farmland, insert the drainage baffle 3, and the water body pollutants near ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com