Batch ring spinning nanofiber/short fiber covering yarn device and method

A nanofiber, ring spinning technology, applied in spinning machines, fiber processing, continuous winding spinning machines, etc., can solve the problems of easy wear and poor durability, avoid wear problems, solve easy wear, functional Durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

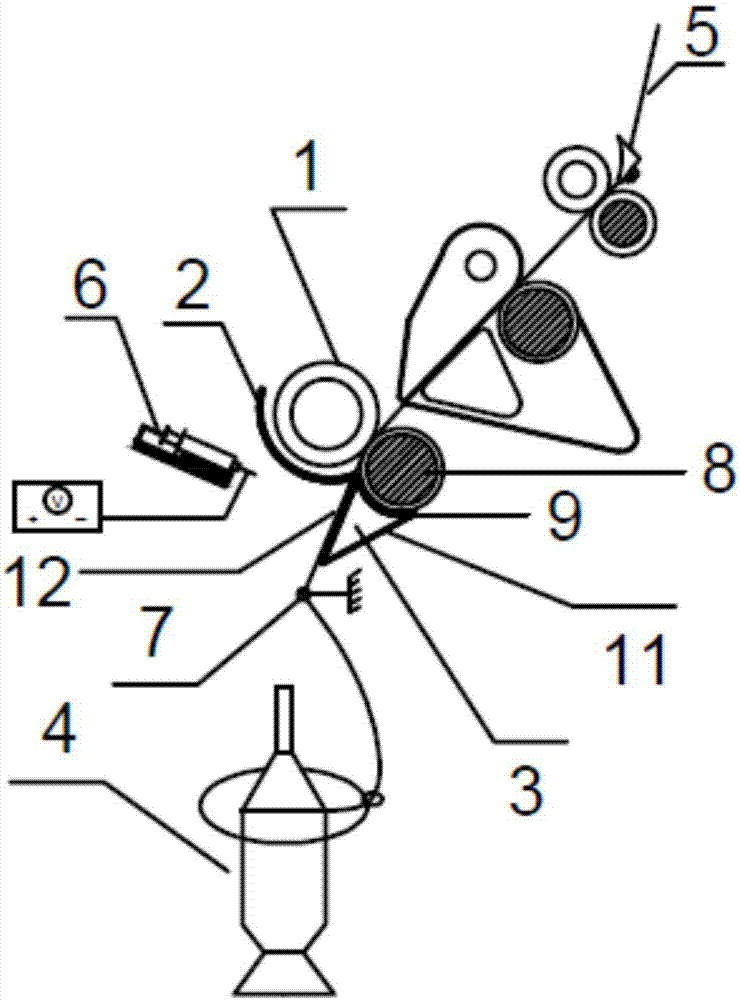

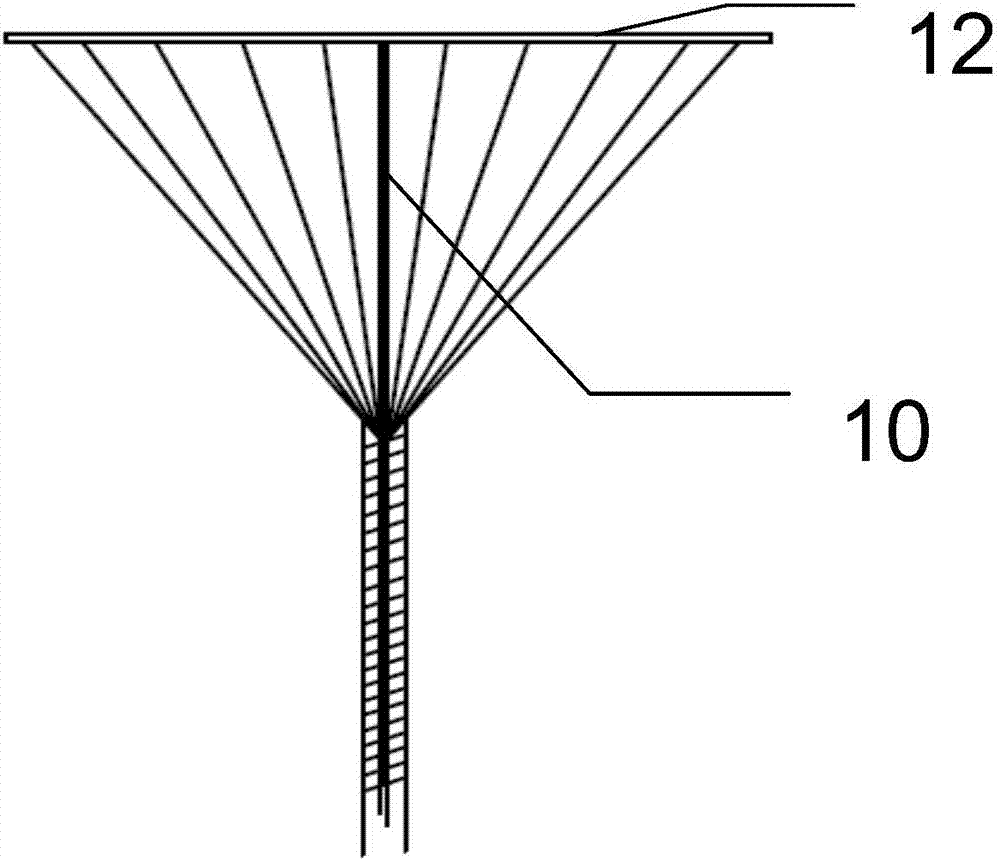

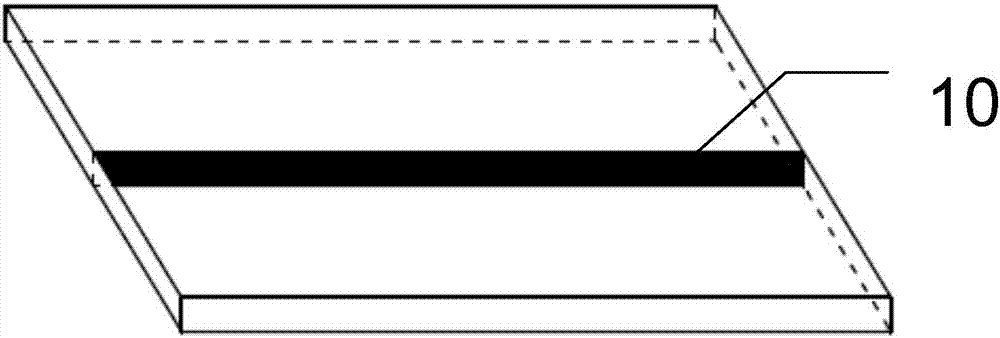

[0032] This embodiment provides a batch ring spinning nanofiber / spun fiber core-spun device, including a ring spinning frame, which includes a front rubber roller 1, a front roller 8, and a first insulating plate 2. Oriented and fixed-point deposition device 3, spun yarn winding device 4, yarn guide hook 7 and single-needle electrospinning machine 6, front rubber roller 1 and front roller 8 form the front roller nip, single-needle electrospinning machine 6 It is arranged between the front roller jaw and the yarn guide hook 7, the directional fixed-point deposition device 3 is arranged under the single-needle electrospinning machine 6, the first insulating plate 2 is arranged under the front rubber roller 1, and the yarn guide hook 7 It is connected with the spun yarn winding device 4; wherein the directional fixed-point deposition device 3 is composed of a second insulating plate 9, a third insulating plate 11, a fourth insulating plate 12 and a metal copper sheet 10, and the s...

Embodiment 2

[0037] This embodiment provides a method for batching ring-spinning nanofiber / spun core-spun yarn, and the specific steps are as follows:

[0038] (1) 10g polyacrylonitrile (molecular weight is 78000) is dissolved in 88gDMF, then adds 2g triclosan antibacterial agent, stirs evenly in magnetic stirrer, the concentration that obtains triclosan antibacterial agent is 2wt%, polyacrylonitrile A homogeneous spinning solution with a concentration of 10 wt%.

[0039] (2) Opening, removing impurities, mixing, carding, combing, drawing (1-2 passes) and roving of cotton staple fiber to obtain roving 5, and feeding roving 5 into the ring spinning frame to obtain sliver , after multiple drafts in the front and rear drafting areas, the strands are continuously thinned, and output through the nip of the front roller, forming a spinning triangle area on the directional fixed-point depositing device 3.

[0040] (3) Put the spinning solution in step (1) into the single-needle electrospinning m...

Embodiment 3

[0042] This embodiment provides a method for batching ring-spinning nanofiber / spun core-spun yarn, and the specific steps are as follows:

[0043] (1) 10g polyacrylonitrile (molecular weight is 78000) is dissolved in 88gDMF, then adds 2g nano-zinc oxide powder, stirs evenly in magnetic stirrer, the concentration that obtains nano-zinc oxide is 2wt%, polyacrylonitrile concentration is 10 wt% homogeneous spinning solution.

[0044] (2) Opening, removing impurities, mixing, carding, combing, drawing (1-2 passes) and roving of cotton staple fiber to obtain roving 5, and feeding roving 5 into the ring spinning frame to obtain sliver , after multiple drafts in the front and rear drafting areas, the strands are continuously thinned, and output through the nip of the front roller, forming a spinning triangle area on the directional fixed-point depositing device 3.

[0045] (3) Put the spinning solution in step (1) into the single-needle electrospinning machine 6 for electrospinning, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com