Single-spiral embedded excitation type magnesium vacuum reduction furnace adopting electromagnetic induction inner heating

An electromagnetic induction, single-spiral technology, applied to high vapor pressure metal equipment, single-spiral embedded excitation electromagnetic induction internal heating magnesium vacuum reduction furnace field, can solve the high cost of reactive power compensation capacitor, large leakage inductance, excitation coil loss Serious problems, to achieve the effect of reducing the relative surface area, rapid heat conduction, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

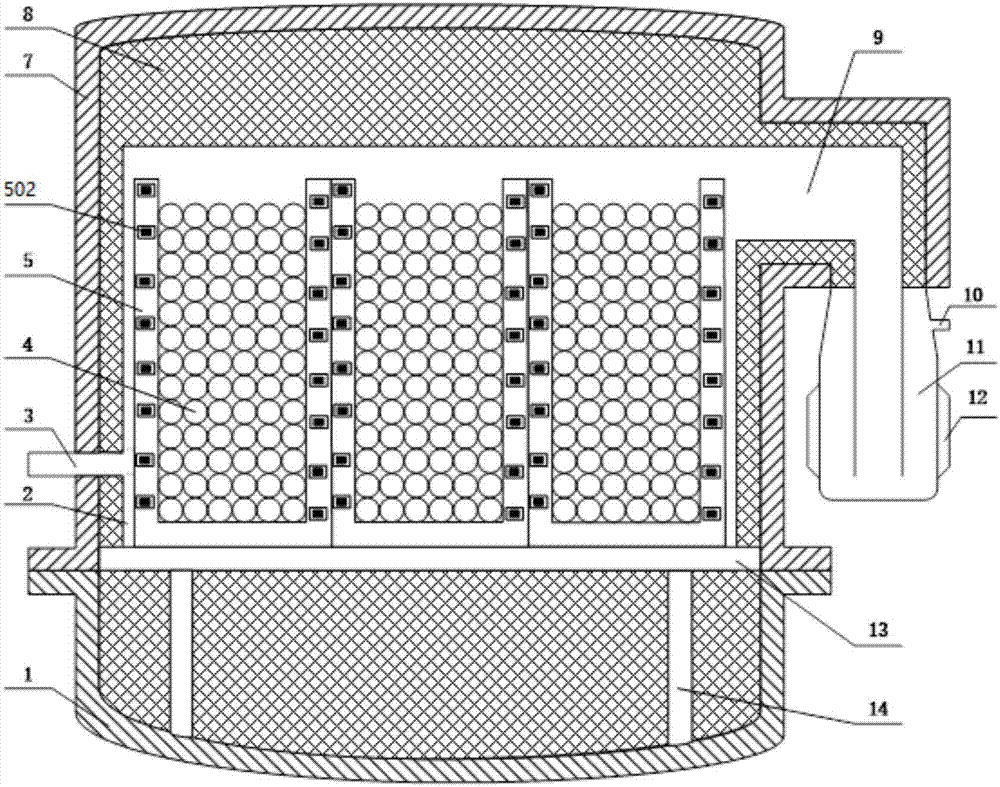

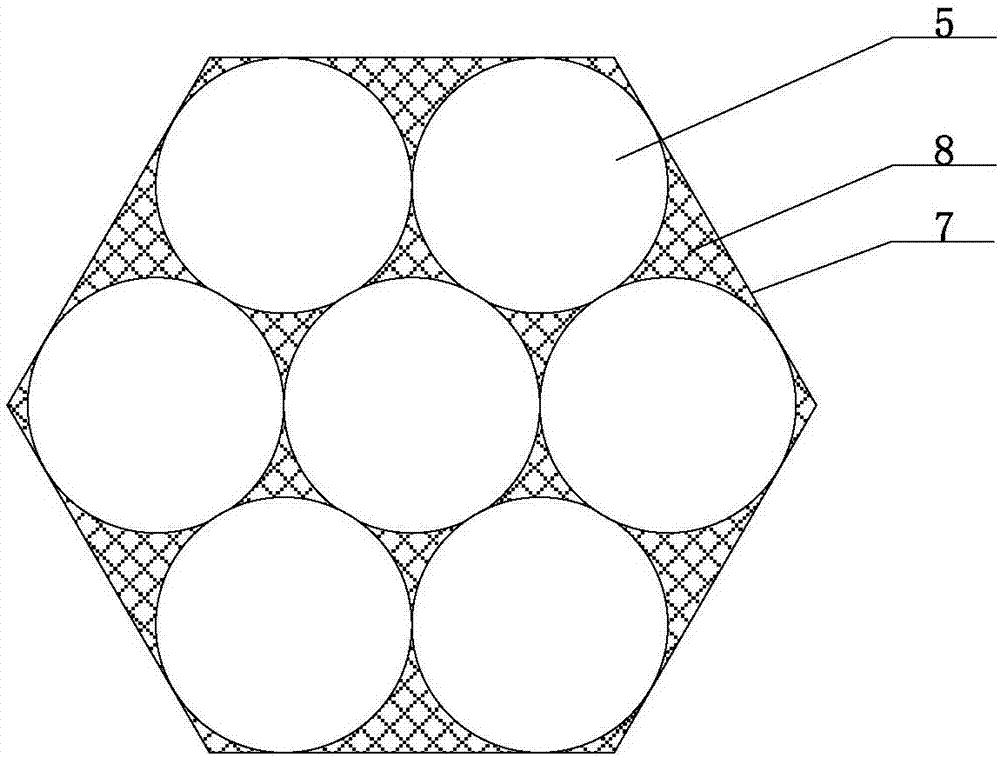

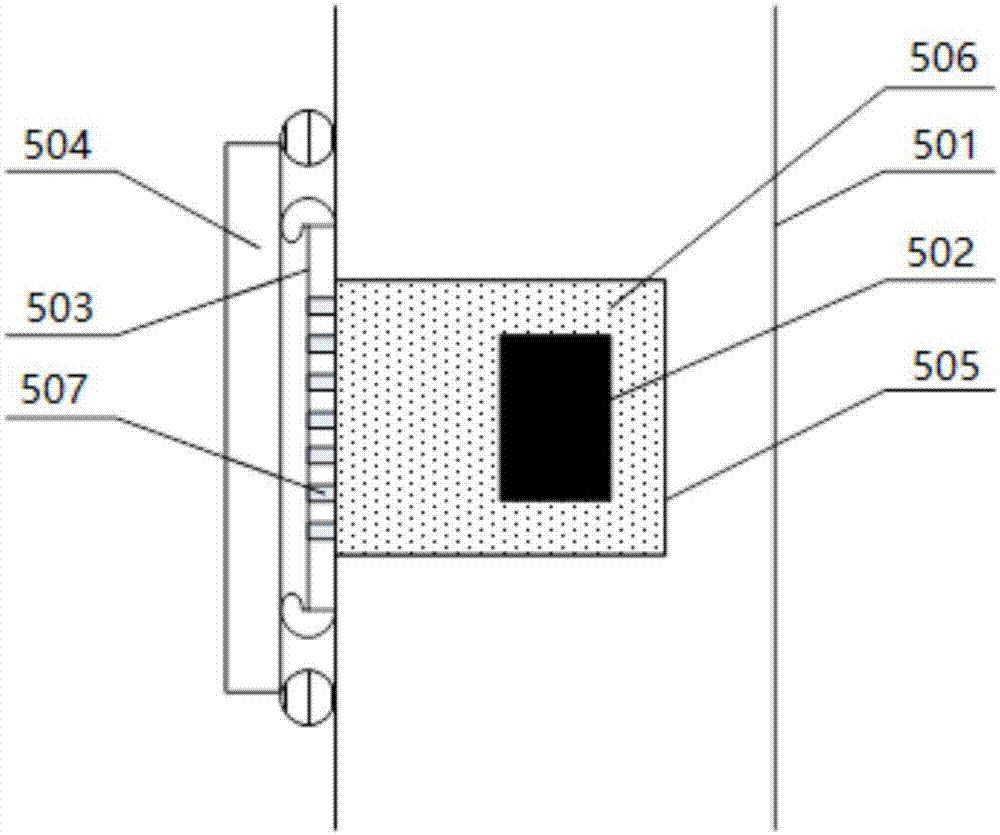

[0030] Such as Figure 1-4 As shown, a single-helix embedded excitation type electromagnetic induction internal heat magnesium vacuum reduction furnace in this embodiment includes an upper furnace shell 7, a lower furnace cover 1, a material basket 5, a platform 13, a support frame 14, a crystallization chamber 11 and Water cooling jacket 12, the material basket 5 is composed of a basket 501, an excitation coil 502, a metal baffle 503 and a steel belt 504, the basket 501 is made of heat-resistant steel, and a single The spiral groove 505 has a single spiral magnesium steam overflow slot 509 on the outer wall of the casing 501, and is arranged parallel to the groove 505. The excitation coil 502 is arranged in the groove 505. The conductor cross section of the excitation coil 502 is rectangular and is a single Excitation coil, the excitation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com