Melting, casting and welding processing technology and device for lead-acid storage battery

A technology of lead-acid battery and processing technology, which is applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. It can solve the problems of large heat consumption, low production efficiency, low work efficiency, etc., and achieve a change in the working environment , Eliminate thermal stress and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

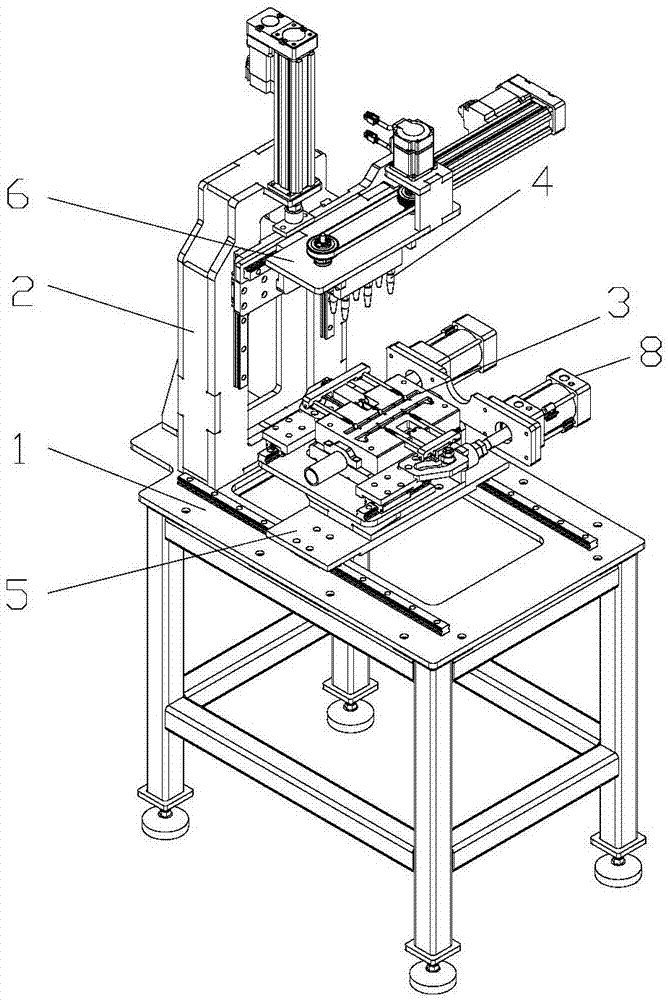

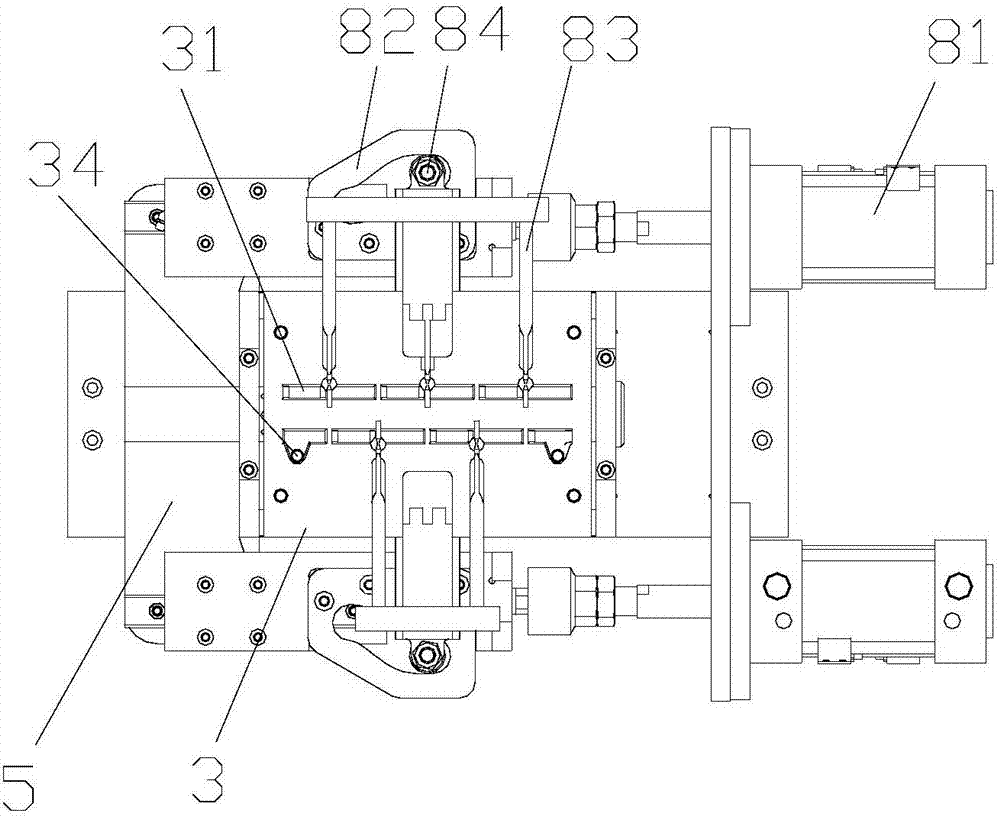

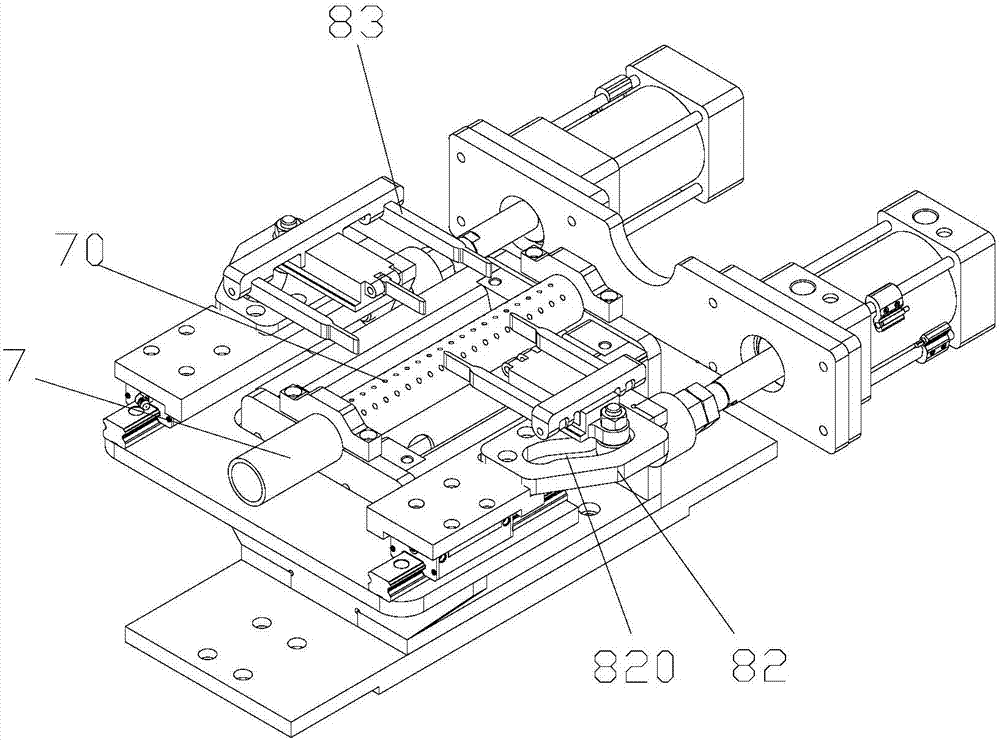

[0041] The present invention as Figure 1-11 As shown, the lead-acid storage battery includes clusters 91, and the clusters include positive plates 92 and negative plates 93 arranged at intervals, and the tabs 94 on the positive plates 92 are located on the same straight line to form a group of positive tabs, and the tabs on the negative plates 93 are The tabs 94 are located on the same straight line to form a negative tab group;

[0042] Described casting welding process comprises the following steps:

[0043] S1. The mold 3 is preheated by the welding torch 4, and the welding torch can move back and forth to heat the mold;

[0044] S2, put the lead material into the two rows of cast welding 31 cavities of the mold 3, and heat the torch to make it melt to form lead liquid;

[0045] S3, put the positive pole ear group and the negative pole ear group on the cluster into two rows of casting and welding cavities respectively;

[0046] S4, cooling, taking out is completed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com