Preparation method of anion-exchange membrane with univalence and multivalence selective separation functions

An anion-exchange membrane and functional technology, applied in the field of separation membranes, can solve the problems of easy peeling off of the modified layer, increase of membrane resistance, increase of membrane thickness, etc., and achieve the effect of good unit-price selective separation function and low increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

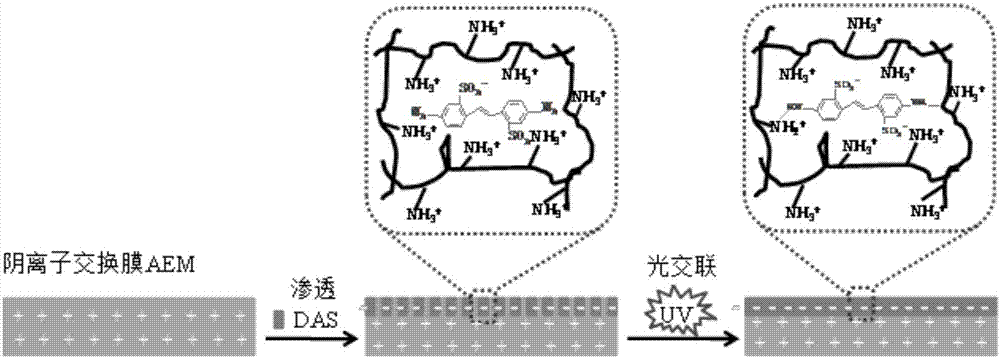

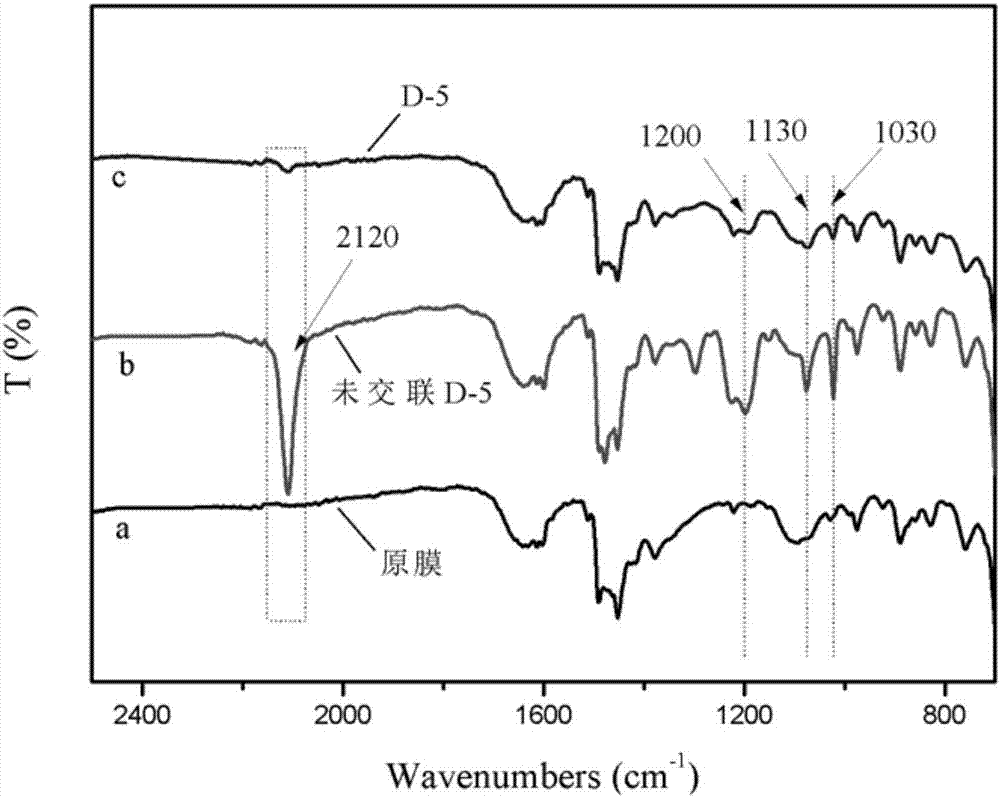

[0032] Commercially available homogeneous anion exchange membranes (JAM-II-07, Beijing Tingrun, China) were cut into appropriate sizes, soaked in pure water to remove hydrophilic substances on the surface, and stored in pure water for later use. Weigh 0.50g of DAS powder, dissolve it in pure water, adjust the pH of the solution to 3.8 with dilute hydrochloric acid, and prepare a 100mL solution.

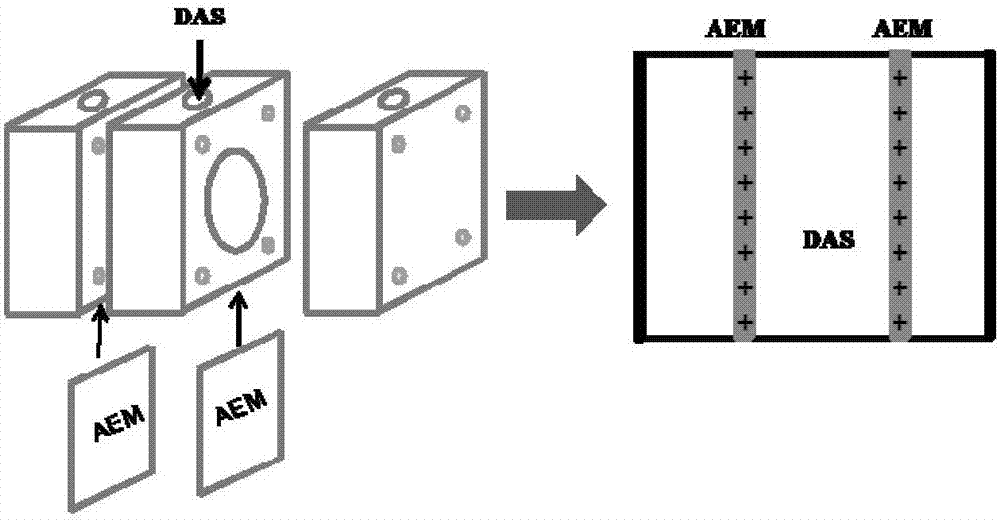

[0033] Fix two anion exchange membranes in a laboratory-made three-compartment device, such as figure 2 As shown, add 100mL of 5.0mg / mL DAS solution (pH=3.8) in the middle compartment, soak on one side for 1min, then take out the membrane, crosslink under ultraviolet light for 30min, and finally store the membrane in pure water, label for S-1.

Embodiment 2

[0035] The soaking time of one side in the above-mentioned Example 1 was increased to 3 minutes, and other steps and conditions remained unchanged, and the obtained film was marked as S-3.

Embodiment 3

[0037] The soaking time of one side in the above-mentioned Example 1 was increased to 5 minutes, and other steps and conditions remained unchanged, and the obtained film was marked as S-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com