Redox-response microsphere and preparing and degradation methods

A responsive, microsphere technology, applied in microsphere preparation, microcapsule preparation, plastic recycling, etc., can solve the problems of difficult processing, small pore size and wall thickness of materials, and limit the application of microspheres, so as to achieve thorough reaction and uniform distribution , the effect of fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

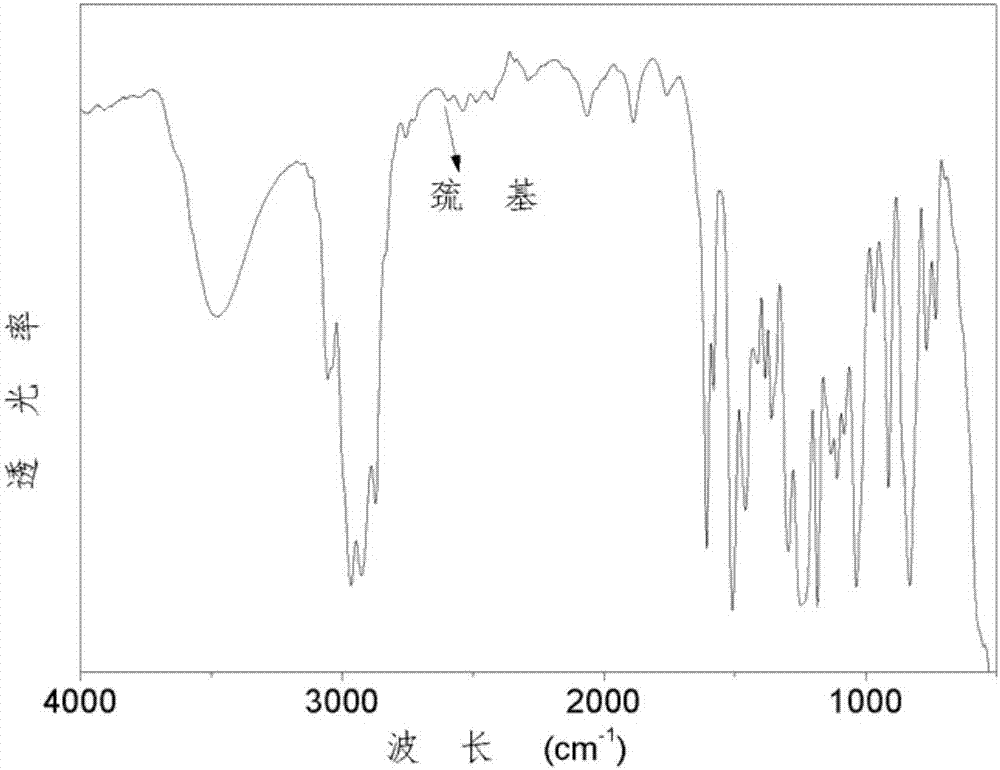

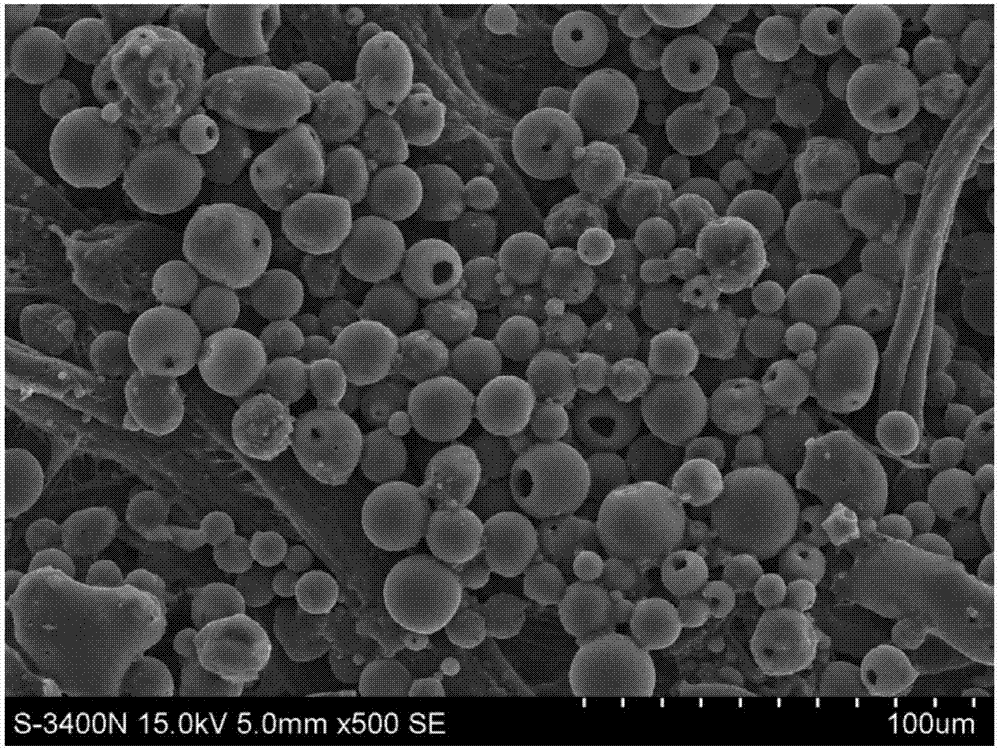

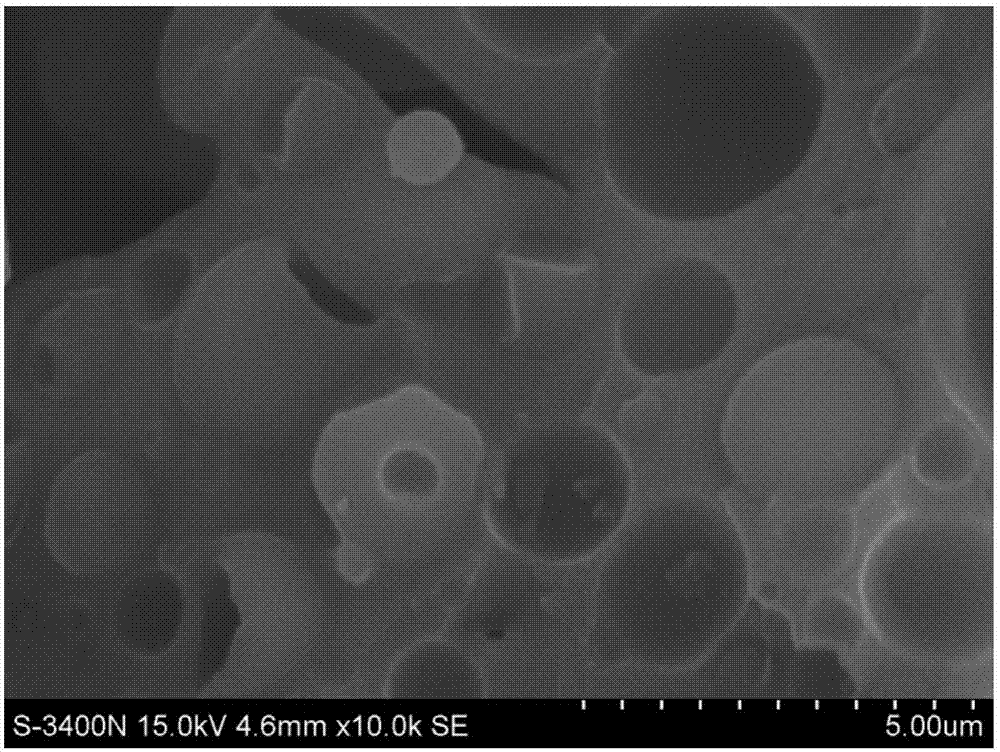

[0038] (1) Preparation of redox-responsive microspheres: 1.4g of octavinyl clathrate silsesquioxane, 1.4g of elemental sulfur / alicyclic olefin copolymer (obtained according to patent CN 201510207935.1), 0.14g of hexadecanon alkanes, dissolved in 2 g tetrahydrofuran to form an organic phase. 0.14 g of surfactant was dissolved in 10 g of deionized water to form the aqueous phase. Mix the organic phase and the water phase, and stir mechanically (stirring speed 600r / min, time 30min). Ultrasonic emulsification (ultrasonic power is 100W, ultrasonic time is 10min), while rapid stirring (stirring speed is maintained at 600r / min). The emulsion was irradiated with ultraviolet light (365nm wavelength irradiation, the irradiation time was 10min), and at the same time, it was stirred rapidly (stirring speed was 600r / min, and the time was 10min). Vacuum-dried at 30°C for 24 hours to obtain redox-responsive microspheres.

[0039] (2) Degradation of redox-responsive microspheres: mix 0.1g ...

Embodiment 2

[0042] (1) Preparation of redox-responsive microspheres: 1.4g of octavinyl clathrate silsesquioxane, 2.8g of elemental sulfur / alicyclic olefin copolymer, and 0.14g of n-hexadecane were dissolved in 2g of tetrahydrofuran to form The organic phase. 0.14 g of surfactant was dissolved in 10 g of deionized water to form the aqueous phase. Mix the organic phase and the water phase, and stir mechanically (stirring speed 600r / min, time 30min). Ultrasonic emulsification (ultrasonic power is 100W, ultrasonic time is 10min), while rapid stirring (stirring speed is maintained at 600r / min). The emulsion was irradiated with an ultraviolet lamp (365nm wavelength irradiation, the irradiation time was 10min), and at the same time, it was stirred rapidly (stirring speed was 600r / min, and the time was 10min). Vacuum-dried at 30°C for 24 hours to obtain redox-responsive microspheres.

[0043] (2) Degradation of redox-responsive microspheres: mix 0.1g microspheres with 0.1g 30wt.%H 2 o 2 The ...

Embodiment 3

[0045] (1) Preparation of redox-responsive microspheres: 1.4g of octavinyl clathrate silsesquioxane, 2.8g of elemental sulfur / alicyclic olefin copolymer, and 0.28g of n-hexadecane were dissolved in 5g of tetrahydrofuran to form The organic phase. 0.28 g of surfactant was dissolved in 10 g of deionized water to form the aqueous phase. Mix the organic phase and the water phase, and stir mechanically (stirring speed 600r / min, time 30min). Ultrasonic emulsification (ultrasonic power is 100W, ultrasonic time is 10min), while rapid stirring (stirring speed is maintained at 600r / min). The emulsion was irradiated with ultraviolet light (365nm wavelength irradiation, the irradiation time was 10min), and at the same time, it was stirred rapidly (stirring speed was 600rad r / min, and the time was 10min). Vacuum-dried at 30°C for 24 hours to obtain redox-responsive microspheres.

[0046] (2) Degradation of redox-responsive microspheres: mix 0.1g microspheres with 0.05g 30wt.%H 2 o 2Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com