Glass cover sheet of solar cell panel

A technology for solar panels and glass cover sheets, applied in glass/slag layered products, circuits, electronic equipment, etc., can solve the problems of solar damage, affecting power generation effect, poor anti-reflection film strength and weather resistance, etc. cracking, good wear resistance and durability, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

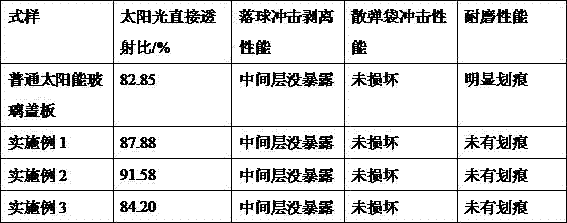

Embodiment 1

[0025] The solar cell panel glass cover sheet is characterized in that it includes a four-layer structure, which is sequentially from top to bottom: a surface layer elastomer film, a first tempered glass, an interlayer elastomer film, and a second tempered glass; the surface layer elastomer The thickness of the film is 1.5 mm, the thickness of the first tempered glass is 2.0 mm, the thickness of the interlayer elastomer film is 0.7 mm, and the thickness of the second tempered glass is 3.0 mm.

[0026] The surface layer elastomer film contains the following components by mass percentage: 65% polyvinyl butyral, 31.3% polyethylene resin, 0.1% anti-wear agent, 3.3% nucleating agent, and 0.3% compatibilizer. Among them, the anti-wear agent can improve the wear resistance of the surface layer elastomer, the nucleating agent can improve the transparency of the surface layer elastomer, and the compatibilizer can make the various components better integrate and obtain a stable blend.

...

Embodiment 2

[0036] The solar cell panel glass cover sheet is characterized in that it includes a four-layer structure, which is sequentially from top to bottom: a surface layer elastomer film, a first tempered glass, an interlayer elastomer film, and a second tempered glass; the surface layer elastomer The thickness of the film is 2.0 mm, the thickness of the first tempered glass is 2.5 mm, the thickness of the interlayer elastomer film is 0.7 mm, and the thickness of the second tempered glass is 3.0 mm.

[0037] The surface layer elastomer film contains the following components by mass percentage: 70% polyvinyl butyral, 25% polyethylene resin, 1.0% anti-wear agent, 2.0% nucleating agent, and 2.0% compatibilizer. Among them, the anti-wear agent can improve the wear resistance of the surface layer elastomer, the nucleating agent can improve the transparency of the surface layer elastomer, and the compatibilizer can make the various components better integrate and obtain a stable blend.

[...

Embodiment 3

[0047]The solar cell panel glass cover sheet is characterized in that it includes a four-layer structure, which is sequentially from top to bottom: a surface layer elastomer film, a first tempered glass, an interlayer elastomer film, and a second tempered glass; the surface layer elastomer The thickness of the film is 1.5 mm, the thickness of the first tempered glass is 2.0 mm, the thickness of the interlayer elastomer film is 0.7 mm, and the thickness of the second tempered glass is 3.0 mm.

[0048] The surface layer elastomer film contains the following components by mass percentage: 85% polyvinyl butyral, 8.8% polyethylene resin, 1.0% anti-wear agent, 0.2% nucleating agent, and 5.0% compatibilizer. Among them, the anti-wear agent can improve the wear resistance of the surface layer elastomer, the nucleating agent can improve the transparency of the surface layer elastomer, and the compatibilizer can make the various components better integrate and obtain a stable blend.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com