Preparation method and application of three-dimensional porous graphene sheet

A graphene sheet, three-dimensional porous technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of complicated process, poor product quality, expensive equipment, etc., and achieve simple process, low cost and high application The effect of value enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

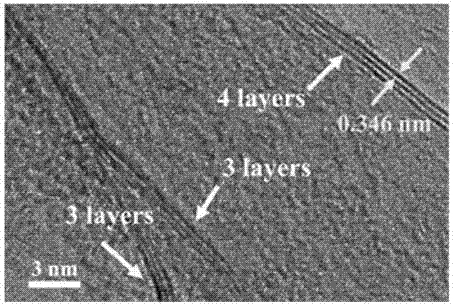

[0039] A method for preparing a three-dimensional porous graphene-like sheet, wherein the three-dimensional porous graphene-like sheet is prepared by a low-temperature graphite method, comprising the following steps:

[0040] Step 1: Separate the inner shell of the biomass, crush it, and sieve to select the powder below 100 microns;

[0041] Step 2: Put the powder obtained in step 1 into a tube furnace and slowly heat up to 350-900°C under the protection of nitrogen to carbonize, and cool to obtain biochar;

[0042] Step 3: Mix and grind the biochar obtained in Step 2 with the catalyst, then slowly raise the temperature to 850-1000°C under a nitrogen atmosphere to react, complete graphitization, and take it out after cooling;

[0043] Step 4: Wash the sample obtained in step 3 to neutrality with deionized water;

[0044] Step 5: put the sample obtained in step 4 into dilute hydrochloric acid and stir;

[0045] Step 6: Wash the sample obtained in step 5 with deionized water a...

Embodiment 1

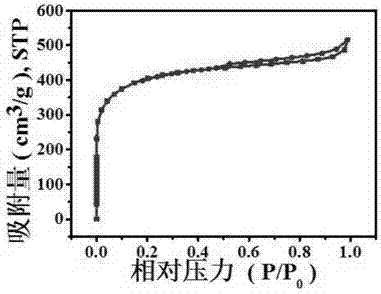

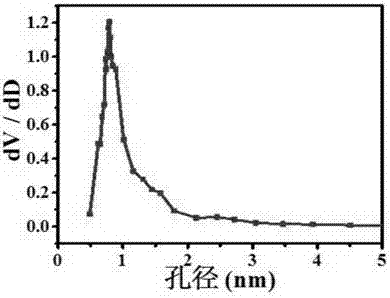

[0053] (1) First separate the inner shell of the coconut shell, then crush it, and sieve to select the powder below 100 microns; put the powder obtained in the above step (1) in a tube furnace, and heat it at 10°C / min under the protection of nitrogen. Raise the temperature to 400°C, then carbonize for 3 hours, and then cool naturally to obtain biochar; mix the biochar obtained in the above step (2) with potassium carbonate at a ratio of 1:6, grind it in a mortar for 5 minutes, and then dry it under a nitrogen atmosphere 10°C / min to raise the temperature to 900°C for 2 hours, take it out after natural cooling; wash the sample taken out in the above step (3) with deionized water to neutrality; put the sample taken out in the above step (4) into 2wt% dilute Stir in hydrochloric acid for 12 hours; the sample taken out in the above step (5) is washed again with deionized water until neutral; the product obtained in the above step (6) is put into a blast drying oven and dried for 12 ...

Embodiment 2

[0055](1) First separate the inner shell of the coconut shell, then pulverize it, and sieve to select the powder below 100 microns; put the powder obtained in the above step (1) in a tube furnace, and heat it at 10°C / min under the protection of nitrogen. Raise the temperature to 500°C, then carbonize for 3 hours, then cool naturally to take out the biochar; mix the biochar obtained in the above step (2) with potassium carbonate at a ratio of 1:6, grind it in a mortar for 5 minutes, and then in a nitrogen atmosphere 10°C / min to raise the temperature to 900°C for 2 hours, take it out after natural cooling; wash the sample taken out in the above step (3) with deionized water to neutrality; put the sample taken out in the above step (4) into 2wt% dilute Stir in hydrochloric acid for 12 hours; the sample taken out in the above step (5) is washed again with deionized water until neutral; the product obtained in the above step (6) is put into a blast drying oven for drying for 12 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com