Optimization method for preparation technology of biodegradable color masterbatch with high covering property

A technology of biodegradation and preparation process, which is applied in the field of optimization of the preparation process of high-coverage biodegradable masterbatches. It can solve problems such as processing difficulties, reducing the biodegradability of PLA materials, and difficulty in the movement of polymer macromolecules. It reaches the analysis range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in combination with specific embodiments.

[0037] In a method for optimizing the preparation process of high-covering biodegradable color masterbatches, the PLA white masterbatch is composed of the following components by weight percentage:

[0038] PLA resin: 70%, titanium dioxide: 30%.

[0039] Its research method is as follows:

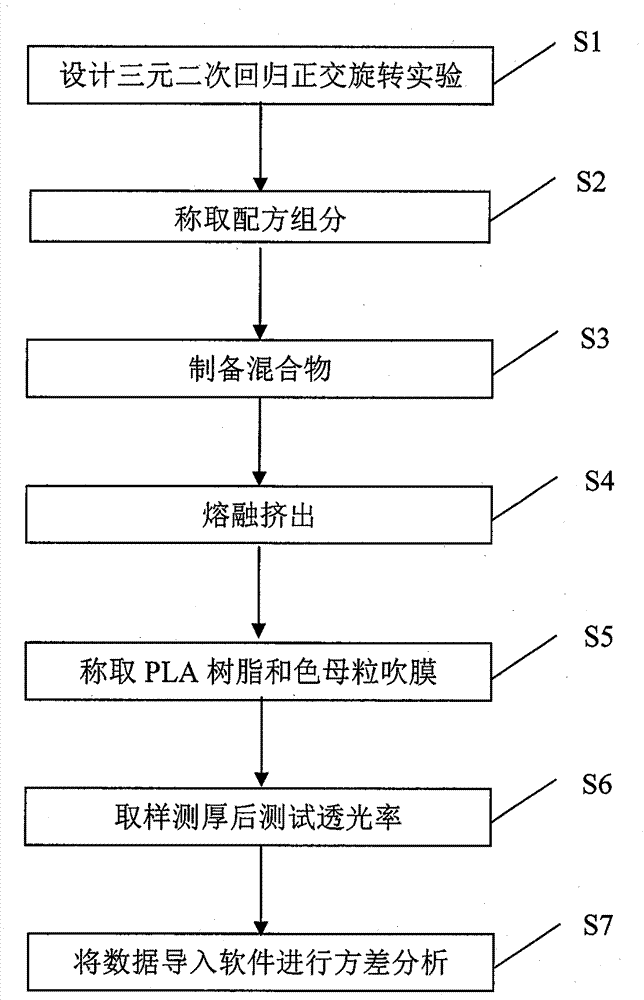

[0040] (1) Design ternary quadratic regression orthogonal rotation experiment

[0041] The boundary range of the plasticizer ratio: 1%-7%; the screw speed is calculated by screw frequency, the boundary range is: 25Hz-30Hz; the temperature boundary range is: 130°C-150°C.

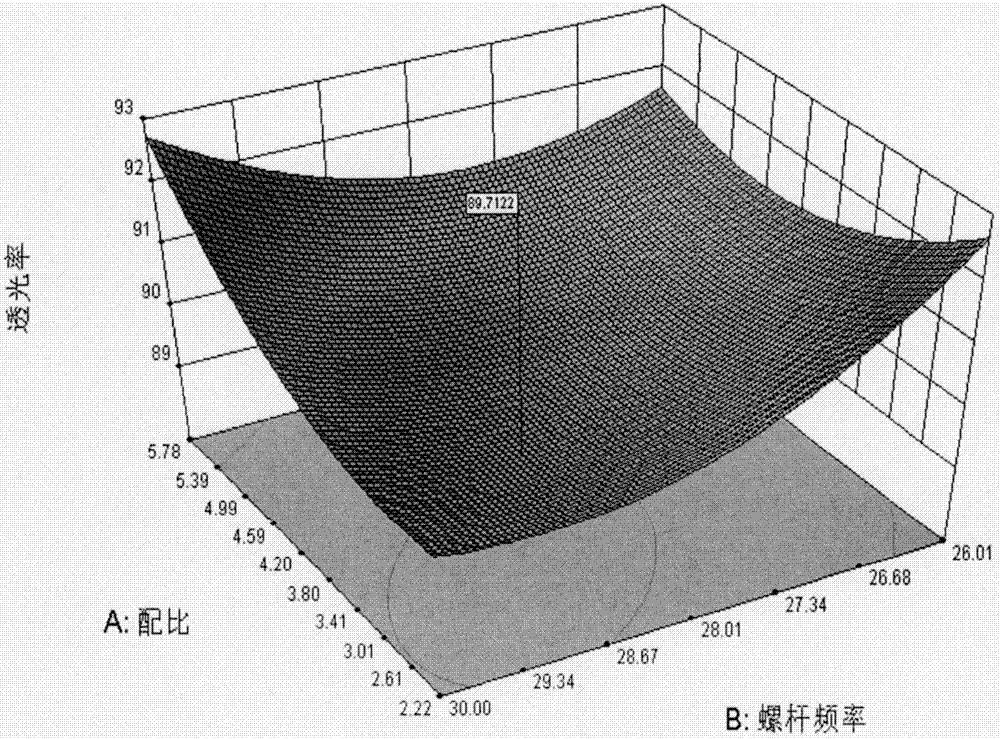

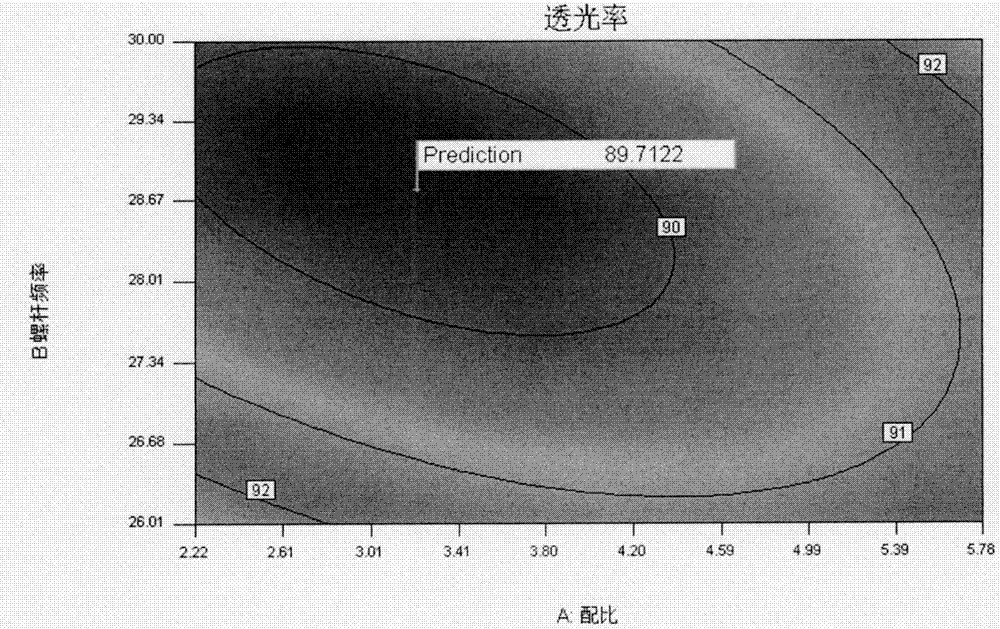

[0042] Select glycerol content (A), twin-screw frequency (B), and twin-screw processing maximum temperature (C) as independent variables. Each factor takes 5 levels, coded as 0, ±1, and ±1.68, respectively. Based on the response value of the light transmittance of the masterbatch, a test with 3 factors and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com