Biomass fast pyrolysis system and pyrolysis method

A biomass pyrolysis and biomass technology, which is applied in the fields of biofuels, gas purification of condensed non-gaseous materials, special forms of dry distillation, etc., can solve the problem of increasing separation cost and inert gas cost, limiting the large-scale pyrolysis furnace, Volume increase and other problems, to avoid explosion hazards, avoid blockage, and increase the reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

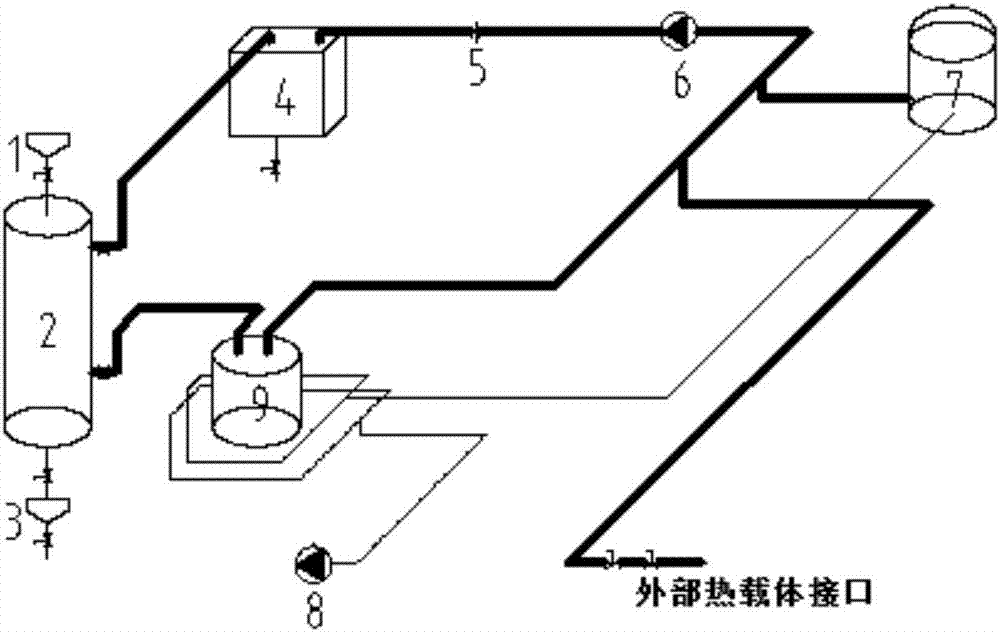

[0036] The present invention will be further described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0037] figure 1 It is a structural schematic diagram of the biomass pyrolysis system of the present invention. The system includes: pyrolysis furnace, intercooler 4, filter 5, gas discharger 6, gas storage tank 7 and heat carrier heating furnace 9.

[0038] The pyrolysis furnace includes a pyrolysis tank 2, a feed hopper 1 arranged at the upper part of the pyrolysis tank 2 and a semi-coke discharge hopper 3 arranged at the bottom of the pyrolysis tank 2, wherein both the feed hopper 1 and the discharge hopper are semi-closed Hopper, when feeding, the material is first put into the hopper 1, and after the hopper 1 is isolated from the outside world, the material enters the pyrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com