Fast-heating wide-range thermogravimetric analyzer

A thermogravimetric analyzer and wide-ranging technology, applied in the field of rapid heating and wide-ranging thermogravimetric analyzers, can solve the problems affecting the stable reading of electronic balances, large system errors, uneven temperature distribution, etc., to reduce the distortion of gas signal concentration and increase the The effect of large contact area and extended application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

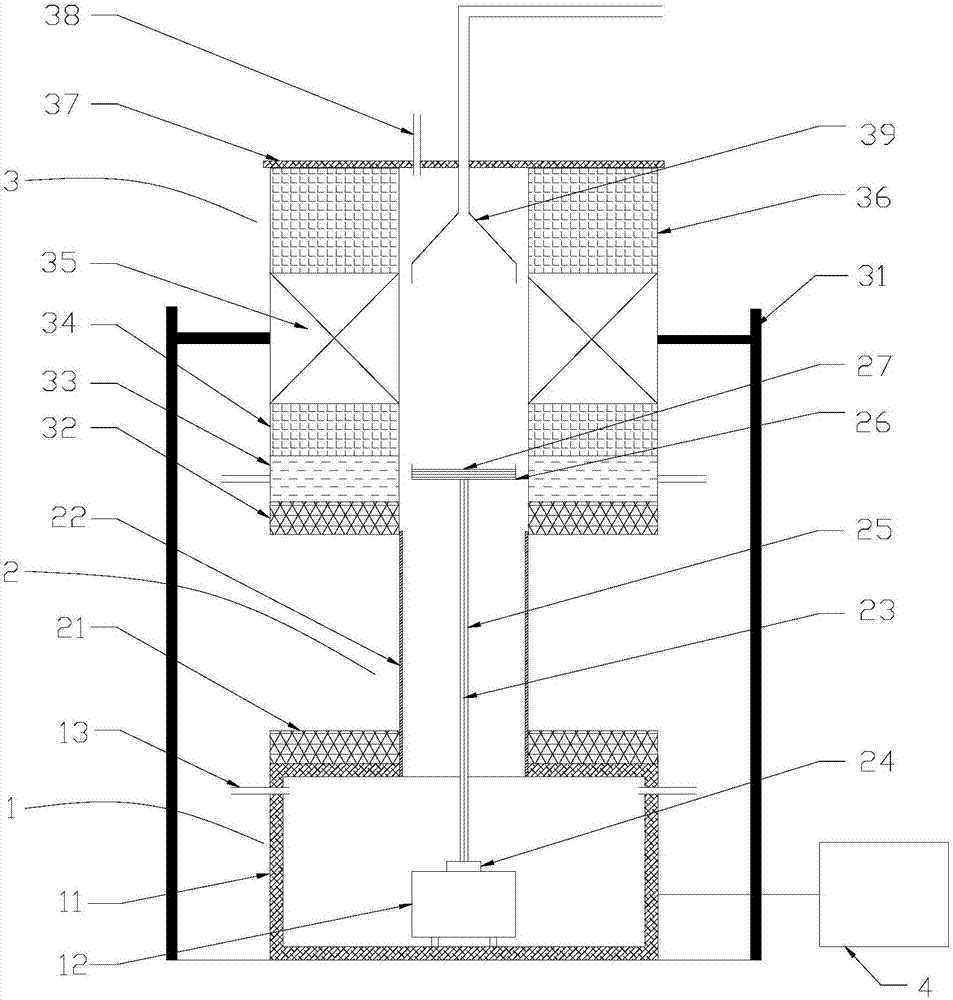

[0032] like figure 1 As shown, the rapid heating and wide-range thermogravimetric analyzer of the present invention includes a weighing system 1 , a reaction system 2 , a heating system 3 and a control system 4 . The weighing system 1 is used to weigh the sample in real time, and the protective gas or reaction gas is introduced into the reaction system 2, which is also used as the support of the entire thermogravimetric analyzer; the reaction system 2 is used to place the sample and measure the temperature of the sample; the heating system 3 It is used to heat samples, discharge gas products, and can automatically rise and fall; the control system 4 is used to monitor and adjust the air intake, water flow and furnace temperature in real time, and collect analysis quality and temperature data. Through the cooperation of the above systems, the quality and temperature measurement of a wide-range sample rapid heating experiment can be achieved, and it is suitable for various react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com