Preheating device for copper wire of coil

A copper wire and coil technology, applied in coil manufacturing, coating, anti-corrosion coating, etc., can solve the problems of wasting time and manpower, incomplete stretching, uneven preheating, etc., and achieve the effect of convenient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

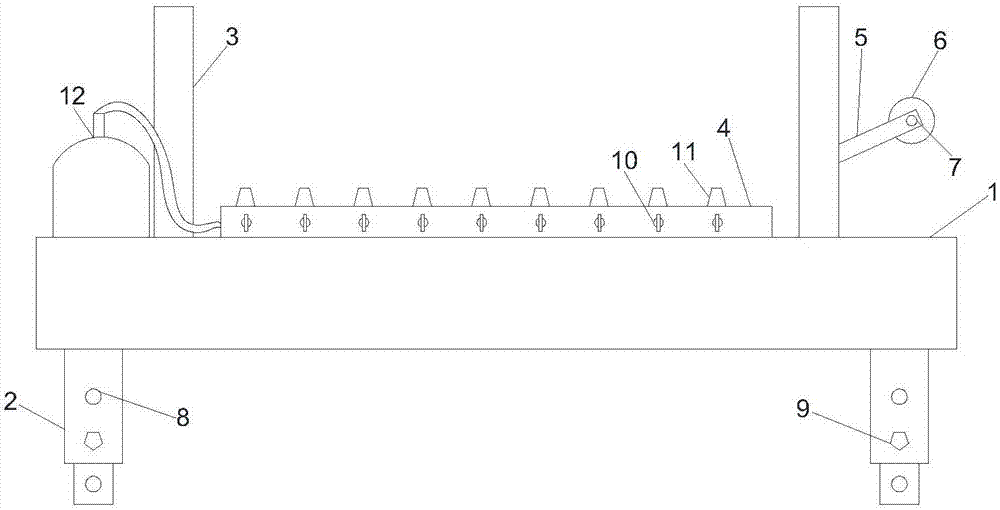

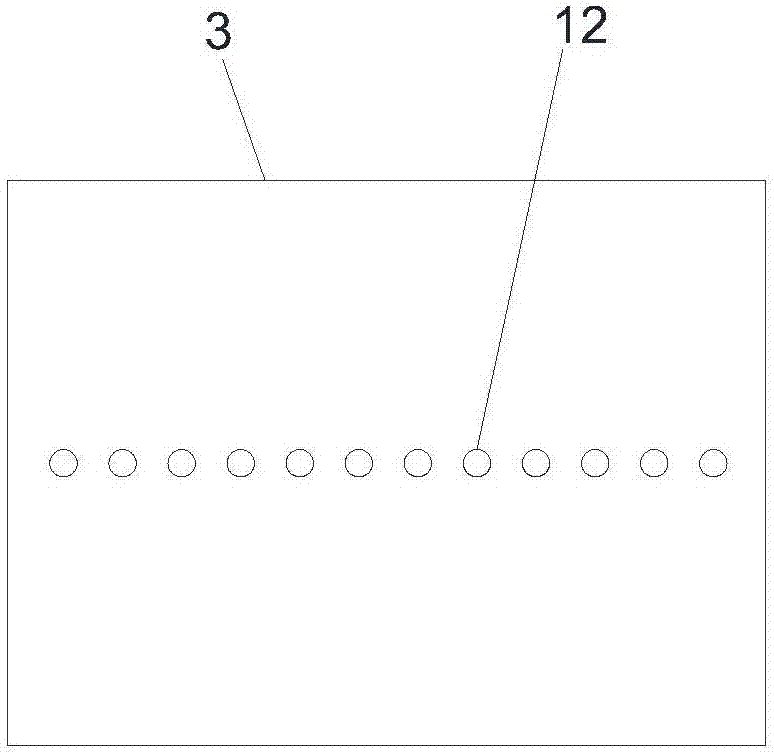

[0035] Such as figure 1 as well as figure 2 As shown, a preheating device for copper wire of a coil includes a base 1, a support frame 2 is connected under the base 1, a fixing plate 3 is installed on the base 1, and a through hole 12 is provided on the fixing plate 3. The base 1 A heater 4 is arranged on the top, and the heater 4 is arranged beside the fixed plate 3. The fixed plate 3 is connected with a connecting rod 5, the connecting rod 5 is provided with a winding roller 6, and the winding roller 6 is provided with a handle 7;

[0036] The support frame 2 is provided with a positioning hole 8, the positioning hole 8 is inserted with a latch 9, and the support frame 2 is a manual telescopic rod;

[0037] The through hole 12 is provided with a protective layer made of rubber;

[0038] The heater 4 is a gas or gas flame nozzle with a switch;

[0039] Described fixed plate 3 is provided with two pieces, and a connecting rod 5 is arranged on one fixed plate 3, and gas tan...

Embodiment 2

[0041] Release coatings used on winding rolls, made of the following materials in parts by weight,

[0042] 11-17 parts of resin, 126-10 parts of nylon, 5-10 parts of modified bentonite, 2-7 parts of triglycidyl isocyanurate, 2-7 parts of polyvinyl carboxybutyraldehyde, 1 hexamethylenetetramine -5 parts, 1-4 parts of methyl benzotriazole, 2-7 parts of coconut acid diethanolamide, 2-7 parts of ethylene glycol dimethacrylate, 8-15 parts of defoamer, biomass 5-10 parts of auxiliary materials, 20-27 parts of water;

[0043] The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0044] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene pentaerythritol ether, polyoxyethylene polyoxypropanolamine ether, polyoxypropylene glyceryl ether;

[0045] The preparation method of the modified bentonite is as follows: grind the bentonite and pass it through a 400-500 m...

Embodiment 3

[0055] Such as figure 1 as well as figure 2 As shown, a preheating device for copper wire of a coil includes a base 1, a support frame 2 is connected under the base 1, a fixing plate 3 is installed on the base 1, and a through hole 12 is provided on the fixing plate 3. The base 1 A heater 4 is arranged on the top, and the heater 4 is arranged beside the fixed plate 3. The fixed plate 3 is connected with a connecting rod 5, the connecting rod 5 is provided with a winding roller 6, and the winding roller 6 is provided with a handle 7;

[0056] The support frame 2 is provided with a positioning hole 8, the positioning hole 8 is inserted with a latch 9, and the support frame 2 is a manual telescopic rod;

[0057] The through hole 12 is provided with a protective layer made of rubber;

[0058] The heater 4 is a gas or gas flame nozzle with a switch;

[0059] The fixed plate 3 is provided with two pieces, a connecting rod 5 is arranged on one fixed plate 3, and a gas tank 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com