A kind of preparation method of ge/c composite nanofiber

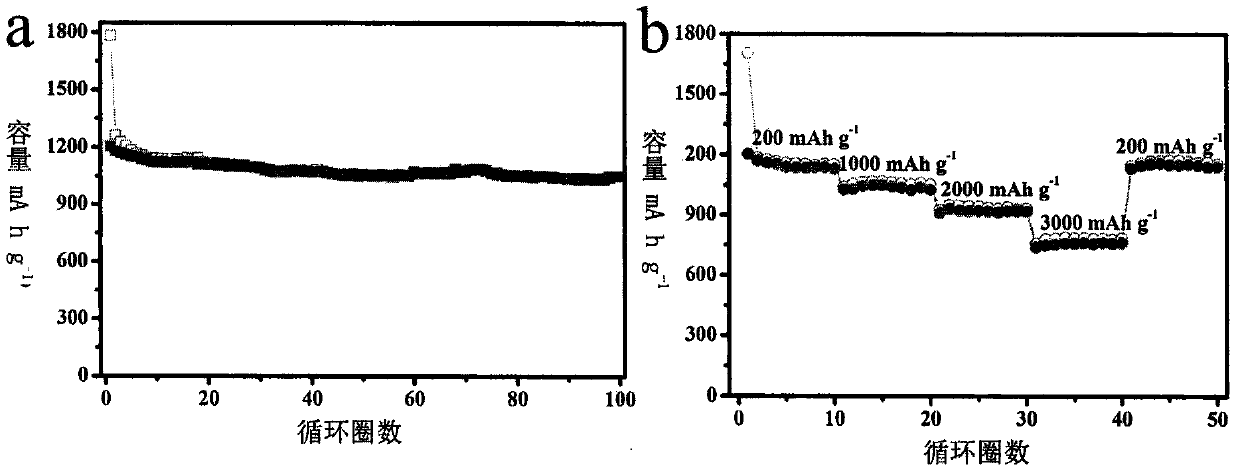

A technology of composite nanofibers and mixed liquids, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficulty in synthesizing Ge nanoparticles, destroying carbon fiber structure, etc., to achieve High rate performance, improved electronic conductivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

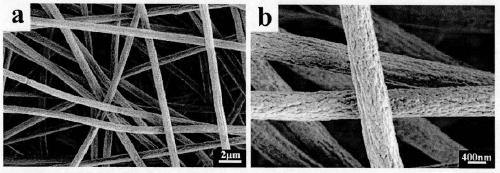

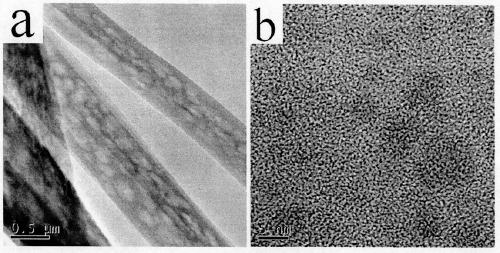

[0033] The specific embodiment of the present invention provides a kind of preparation method of Ge / C composite nanofiber, and this preparation method comprises the following steps:

[0034] 1) Add 0.4~1.0g (such as 0.5g, 0.6g, 0.7g, 0.8g, 0.9g) of polyacrylonitrile to 5~10ml (such as 6ml, 7ml, 8ml, 9ml) of N, N dimethyl In formamide, mix and stir evenly until polyacrylonitrile is completely dissolved in N,N dimethylformamide to obtain a mixed solution;

[0035] 2) Add 0.2-1.5ml (eg 0.3ml, 0.5ml, 0.7ml, 0.8ml, 0.9ml, 1.0ml, 1.1ml, 1.2ml, 1.3ml, 1.4ml) of germanium isopropoxide into step 1) In the obtained mixed solution, stir evenly for 2-4 hours (for example, 2.5 hours, 3 hours, 3.5 hours, 3.8 hours) to obtain a precursor solution.

[0036] 3) Transfer the precursor solution obtained in step 2) to a plastic syringe with a needle inner diameter of 0.9 mm; and set the flow rate with a precision propeller, and place a piece of aluminum foil at a distance of 15 cm from the plast...

Embodiment 1

[0039] A kind of preparation method of Ge / C composite nanofiber, this preparation method comprises the steps:

[0040] 1) Add 0.6g of polyacrylonitrile (molecular weight 150000, Aldrich reagent) to 5ml of N,N dimethylformamide (DMF, Aladdin's reagent), mix and stir until the polyacrylonitrile is completely dissolved to N, In N-dimethylformamide, a mixed solution was obtained;

[0041] 2) Add 1 ml of germanium isopropoxide (Alpha Aesar reagent) solution to the mixed solution obtained in step 1), and stir evenly for 3 hours to obtain a precursor solution.

[0042] 3) Transfer the precursor solution obtained in step 2) to a plastic syringe with a needle inner diameter of 0.9 mm; and set the flow rate with a precision propeller, and place a piece of aluminum foil at a distance of 15 cm from the plastic syringe to collect Nanofiber membrane precursor; wherein, the flow rate set by the precision propeller is 0.2ml min -1 The spinning voltage is set to 15kV; the experimental proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com