Method for preparing lithium carbonate from waste and old trinary lithium ion battery electrode power material

A lithium-ion battery, lithium carbonate technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as pollution recovery rate, and achieve high recovery rate, good environmental compatibility, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

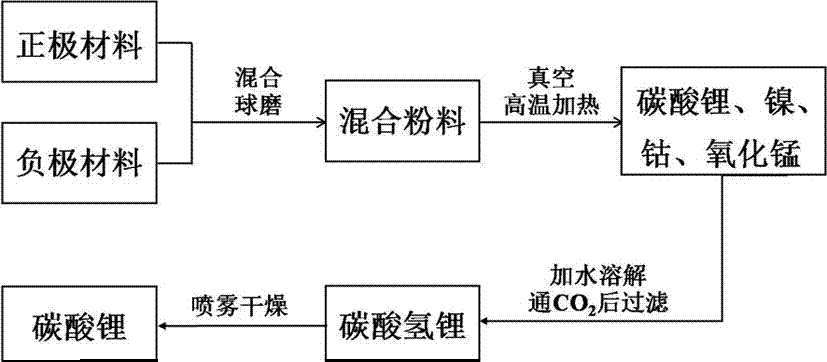

[0033] Embodiment 1: a kind of from waste and old Li (Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The method for producing lithium carbonate in the electrode powder of ternary lithium ion battery, as figure 1 shown, including the following steps:

[0034] (1) Mixing

[0035] The waste Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The electrode powder of the ternary lithium-ion battery is dry mixed. The electrode powder is composed of positive electrode powder and negative electrode powder. The positive electrode powder includes ternary active materials, binders and conductive carbon. The negative electrode powder materials include graphite, Binders and thickeners. The mixed powder is carried out mechanical ball milling, the mass ratio of ball to material is 10: 1, the rotating speed is 250r / min, and the ball milling time is 0.5 h, so that it is evenly mixed;

[0036] (2) Calcination

[0037] The powder mixed in step (1) was calcined in a vacuum high-temperature furnace, the vacuum pressure range of t...

Embodiment 2

[0042] Embodiment 2: a kind of from waste and old Li (Ni 0.5 co 0.2 mn 0.3 )O 2 The method for producing lithium carbonate in the electrode powder of ternary lithium ion battery, as figure 1 shown, including the following steps:

[0043] (1) Mixing

[0044] The waste Li(Ni 0.5 co 0.2 mn 0.3 )O 2 The electrode powder of the ternary lithium-ion battery is dry mixed. The electrode powder is composed of positive electrode powder and negative electrode powder. The positive electrode powder includes ternary active materials, binders and conductive carbon. The negative electrode powder materials include graphite, Binders and thickeners. The mixed powder is carried out mechanical ball milling, the mass ratio of ball to material is 20: 1, the rotating speed is 100 r / min, and the ball milling time is 1 h, so that it is evenly mixed;

[0045] (2) Calcination

[0046] The powder mixed in step (1) was calcined in a vacuum high-temperature furnace, the vacuum pressure range of th...

Embodiment 3

[0051] Embodiment 3: a kind of from waste and old Li (Ni 0.7 co 0.15 mn 0.15 )O 2 The method for producing lithium carbonate in the electrode powder of ternary lithium ion battery, as figure 1 shown, including the following steps:

[0052] (1) Mixing

[0053] The waste Li(Ni 0.7 co 0.15 mn 0.15 )O 2 The electrode powder of the ternary lithium-ion battery is dry mixed. The electrode powder is composed of positive electrode powder and negative electrode powder. The positive electrode powder includes ternary active materials, binders and conductive carbon. The negative electrode powder materials include graphite, Binders and thickeners. The mixed powder is carried out mechanical ball milling, the mass ratio of ball to material is 5: 1, the rotating speed is 500 r / min, and the ball milling time is 0.1 h, so that it is evenly mixed;

[0054] (2) Calcination

[0055] The powder mixed in step (1) was calcined in a vacuum high-temperature furnace, the vacuum pressure range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com