Abelmoschus manihot flower polysaccharide extracting method

A technology for extracting golden sunflower and polysaccharide, which is applied in the field of polysaccharide extraction, can solve problems such as insufficient thoroughness and complex structure, and achieves the effects of reducing loss, simple operation and convenient extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] In a kind of golden flower sunflower polysaccharide extraction method, mainly comprises the following steps:

[0101] Step 1. After the sunflowers are washed, they are put into the reaction chamber of the extractor and dried to a constant weight at a temperature of 60° C. to obtain dried sunflowers, and then crushed to 60 mesh to obtain sunflower powder;

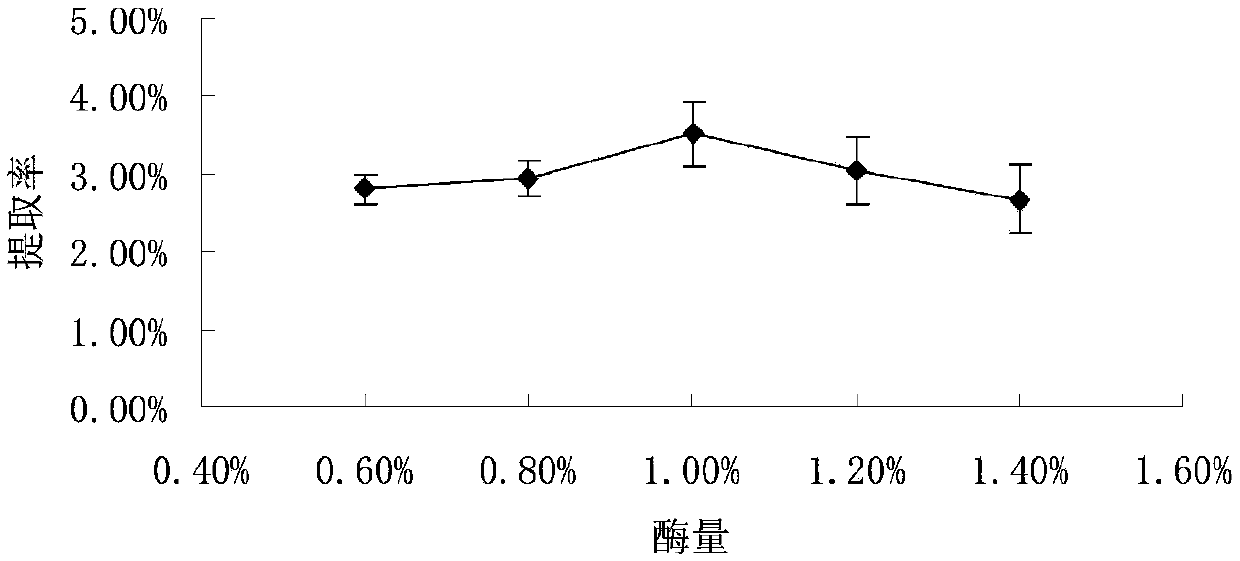

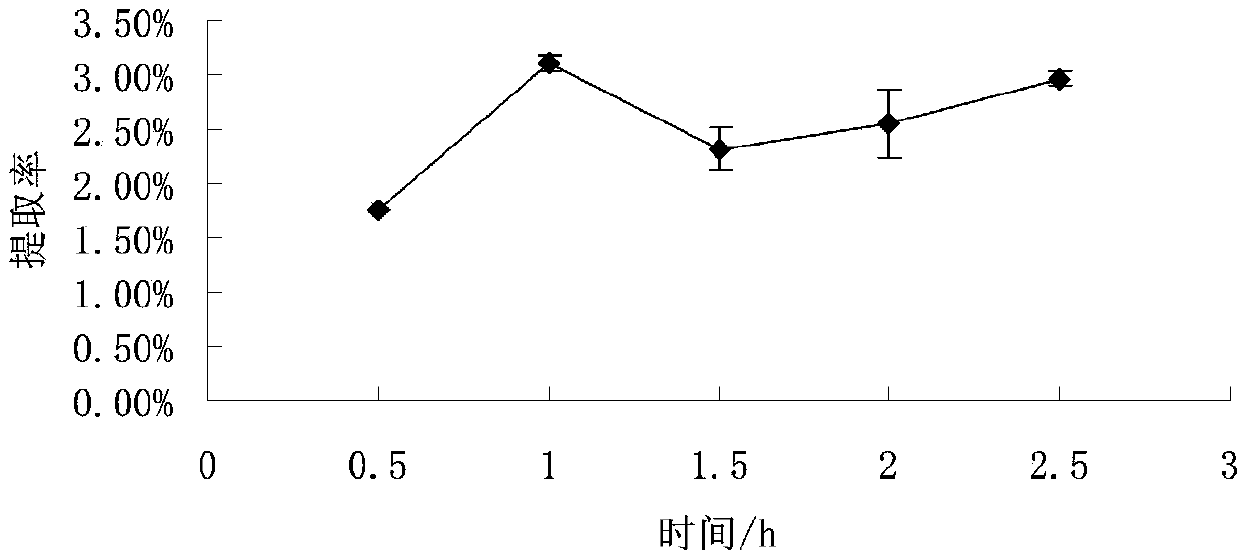

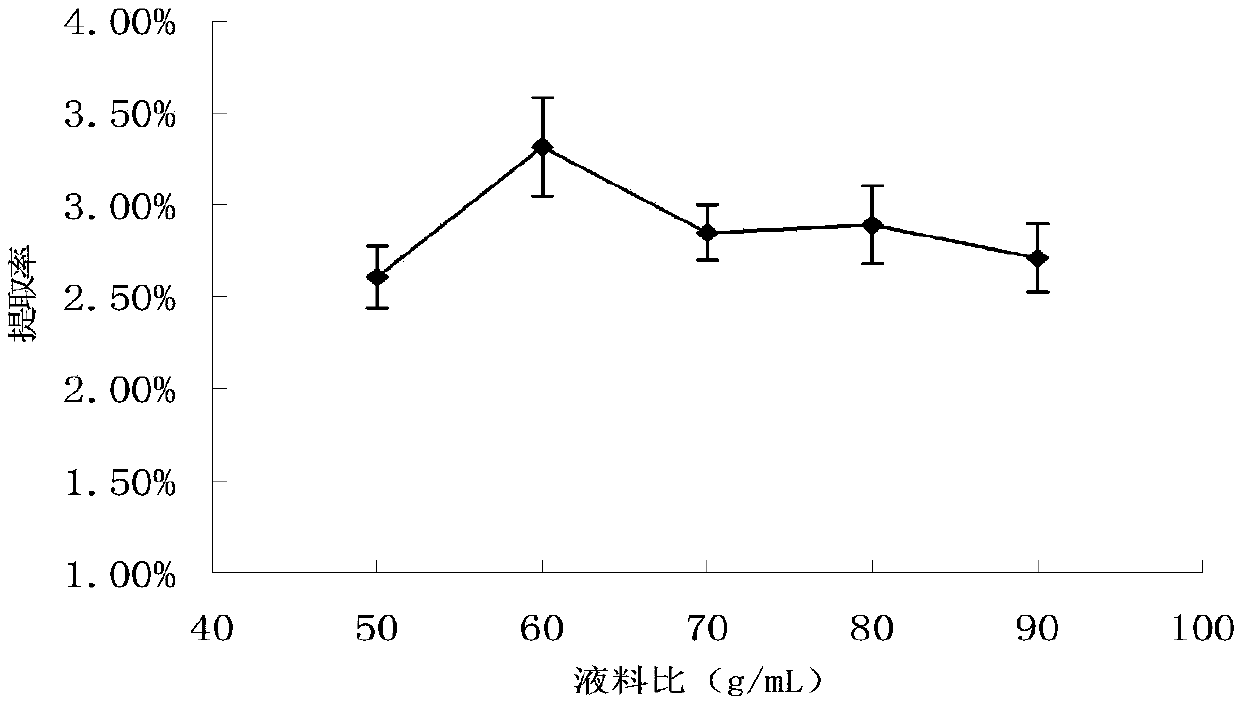

[0102] Step 2, the golden flower sunflower powder obtained is weighed quantitative distilled water according to the solid-liquid ratio 1:58.28g / mL, and the cellulase that accounts for 0.95% of the total mass of the golden flower sunflower powder, and the distilled water and cellulose Enzyme mixing and heating to a temperature of 50°C, adding to the goldenflower sunflower powder and stirring evenly, adjusting the pH value to 7, and continuously stirring for 0.81h to obtain an enzymatic hydrolysis mixture;

[0103] Step 3. After inactivating the enzymolysis mixture at a temperature of 92°C for 10 minutes, centrifuge at ...

Embodiment 2

[0108] In a kind of golden flower sunflower polysaccharide extraction method, mainly comprises the following steps:

[0109] Step 1. Wash the sunflower and store it at 6°C for 4 hours, put it into the reaction chamber of the extractor and dry it for 1.5 hours at a temperature of 60°C, then reduce the temperature of the reaction chamber to 50°C and continue drying for 3 hours. Finally, reduce the temperature of the reaction chamber to 35° C. and dry at a constant temperature to a constant weight to obtain dried sunflower sunflowers, which are crushed to 60 mesh to obtain sunflower sunflower powder;

[0110] Step 2, the golden flower sunflower powder obtained is weighed quantitative distilled water according to the solid-liquid ratio of 1:58.28g / mL, and the cellulase that accounts for 0.95% of the total mass of the golden flower sunflower powder, and the distilled water and cellulose Divide the enzyme into 3 parts equally, and heat 3 parts of distilled water to 60°C, 50°C and 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com