Classified coke discharge method and equipment for carbon hydrogen powder pyrolysis scorching system using solid heat carrier method

A technology of solid heat carrier and hydrocarbon powder, applied in coking ovens, gas dust removal, combustible gas purification, etc., can solve problems such as unreasonable equipment structure, low thermal efficiency of the system, and no successful cases of large-scale commercial devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

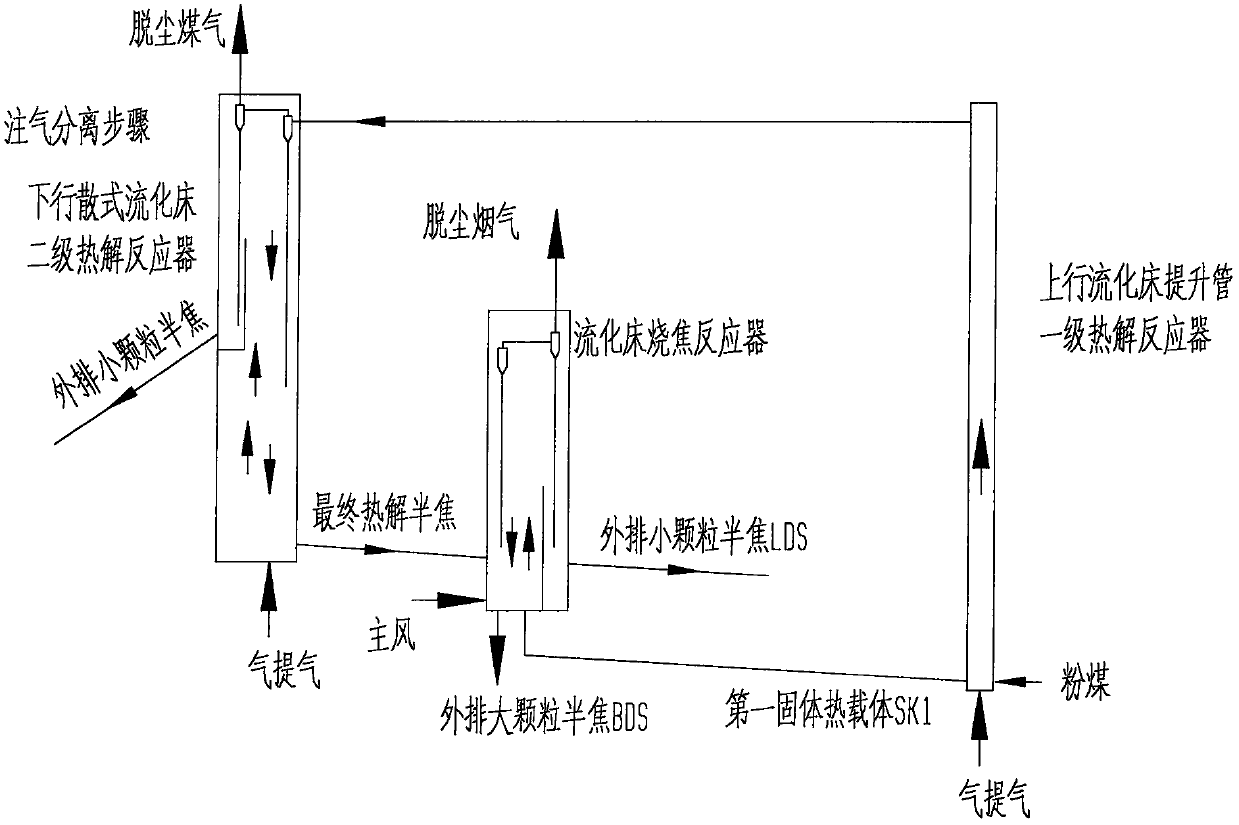

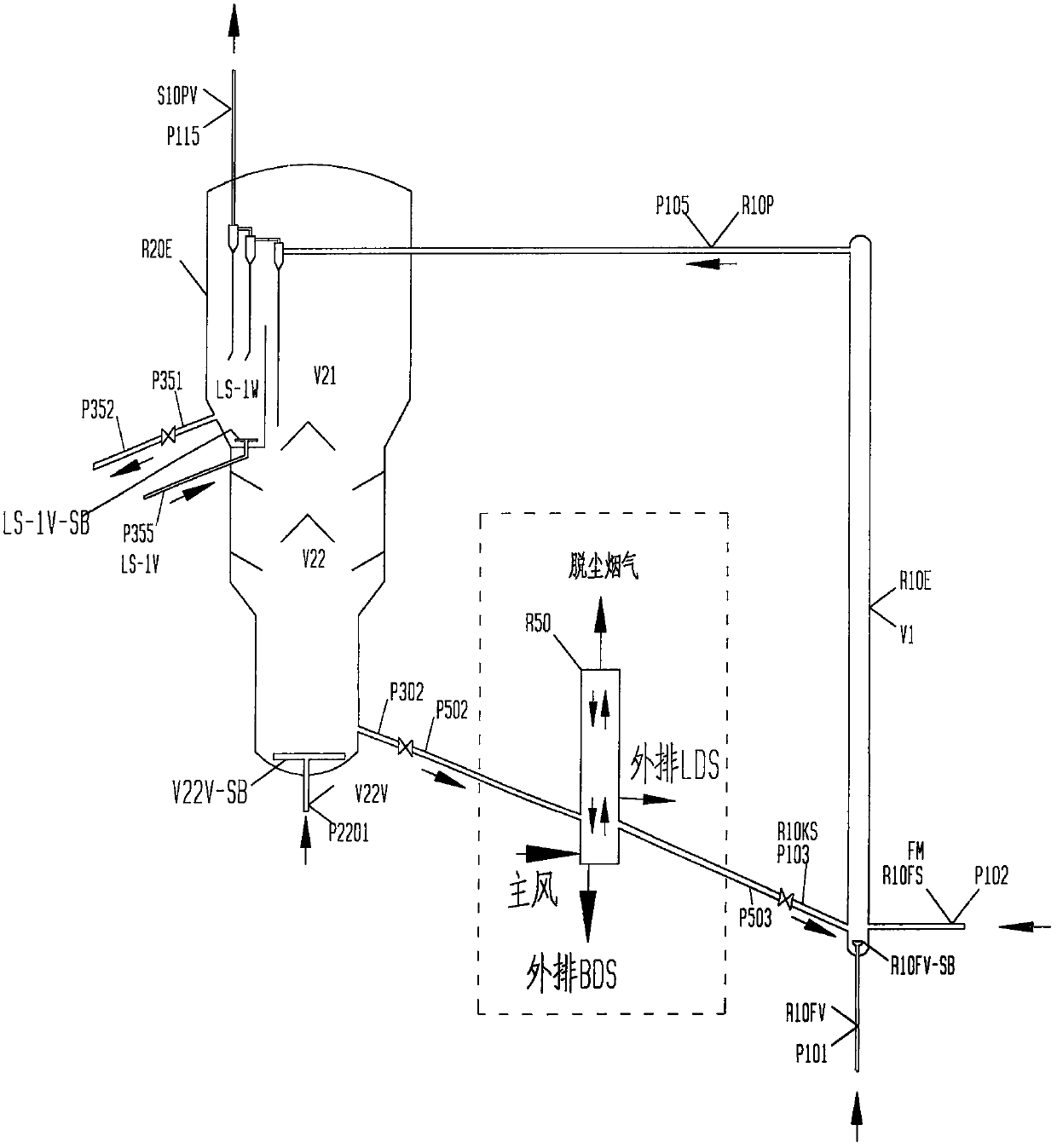

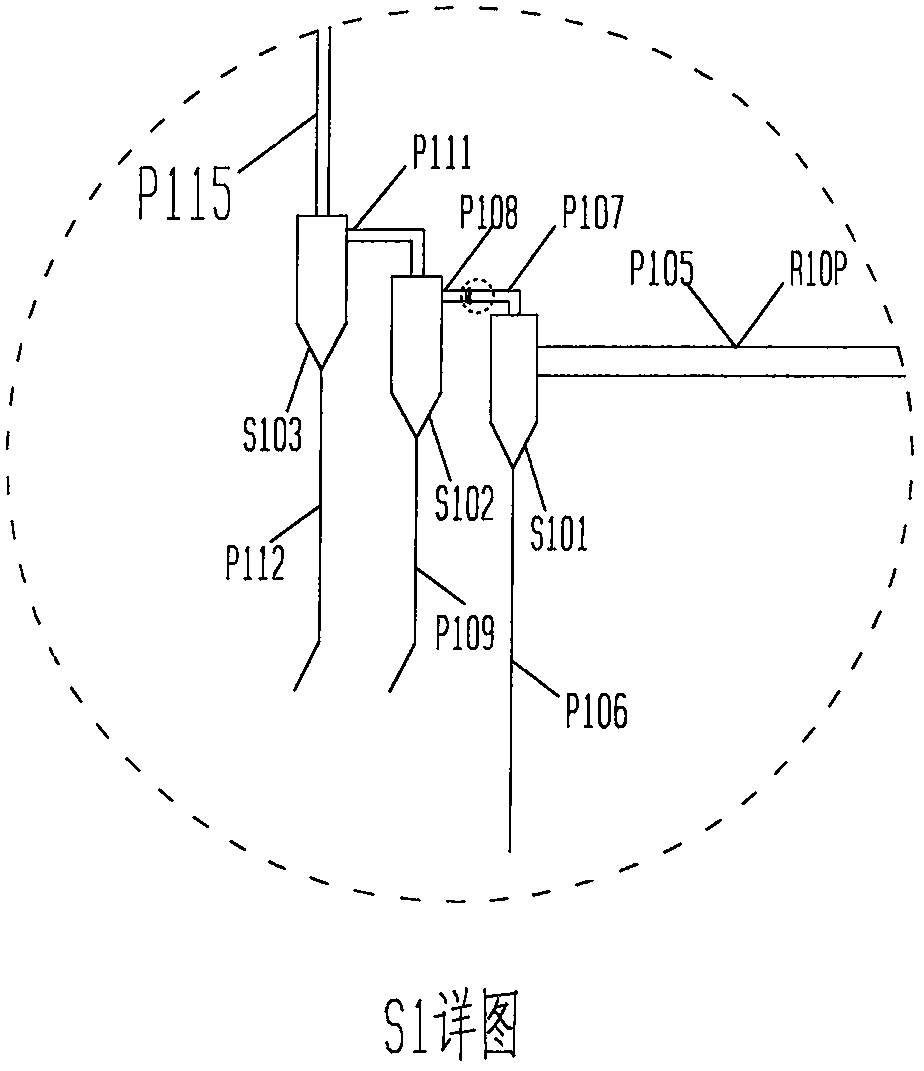

[0220] The method and equipment for classification and coking of the hydrocarbon powder pyrolysis and coking system of the present invention is characterized in that it comprises the following steps: in the hydrocarbon powder R10FS pyrolysis and coking system UNIT using the solid heat carrier R10KS, in At any process position where the solid heat carrier R10KS circulates through, at least a part of the small particles LS below the critical particle size DZ in the material EM containing the solid heat carrier are separated, collected, discharged and recycled, so as to reduce the small particle LS in the solid heat carrier concentration.

[0221] In the present invention, the pyrolysis and coking system UNIT can be composed of a fluidized bed riser pyrolysis reaction process and a fluidized coking reaction process R50:

[0222] In the hydrocarbon powder R10FS pyrolysis and coking system UNIT using the solid heat carrier R10KS, at any process position where the solid heat carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com