Novel cargo oil temperature control system and method for chemical cargo ship

A chemical tanker and temperature control system technology, applied in the field of ship temperature control, can solve the problems of high price, increased shipbuilding cost and difficulty of maintenance and repair, and achieve the effect of easy maintenance, convenient temperature control and consistent temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

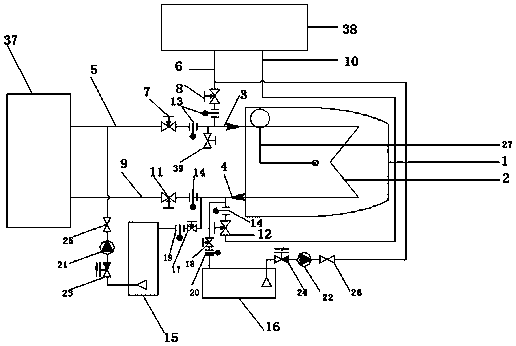

[0030] Such as figure 1As shown, a novel cargo oil temperature control system for chemical tankers includes a liquid cargo tank 1, a deck 40 is provided on the top of the liquid cargo tank 1, and a coil 2 is provided at the bottom of the liquid cargo tank 1, and the coil 2 One end of the coil is connected with a water inlet pipe 3, and the other end of the coil 2 is connected with an outlet pipe 4, and the water inlet pipe 2 is respectively connected with the water outlet pipe 5 of the chiller and the water outlet pipe 6 of the heating equipment located outside the liquid cargo tank 1. The water outlet pipe 5 of the unit is provided with a first water outlet valve 7, the heating equipment outlet pipe 6 is provided with a second water outlet valve 8, and the water outlet positions of the first water outlet valve 7 and the second water outlet valve 8 are respectively provided with water outlet valves. Blind plate 13; the outlet pipe 4 is respectively connected to the water inlet...

Embodiment 2

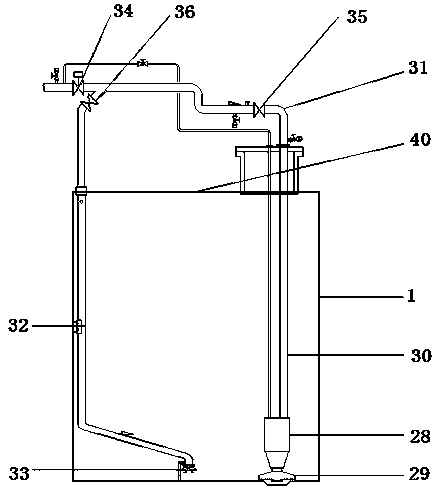

[0034] When the liquid cargo in the liquid cargo tank 1 is cooled by the coil 2, there is a temperature difference between the upper liquid and the lower liquid. In order to solve the above problems, the present invention improves the cargo oil pump for loading and unloading cargo in the liquid cargo tank 1, and the specific scheme is as follows:

[0035] Such as figure 2 As shown, a cooling and heating cycle device 27 is provided in the liquid cargo tank, and the cooling and heating cycle device 27 includes a cargo oil pump. The pump head 28 of the cargo oil pump is located at the bottom of the liquid cargo tank 1, and a liquid suction well is arranged below the pump head 28 29. A cargo oil pump liquid cargo pipe 30 is connected above the pump head 28, and the cargo oil pump liquid cargo pipe 30 extends to the top of the liquid cargo tank 1 and passes through the deck 40 of the liquid cargo tank 1 and the liquid cargo main pipe 31 on the deck 40 The liquid cargo main pipe 3...

Embodiment 3

[0046] System design conditions:

[0047] The outside temperature is 45°C and the seawater temperature is 32°C. The temperature of the two largest cargo tanks (No.6 cargo tanks (center left and center right)) is maintained below 20°C, and the temperature of the cargo loaded into the tank is considered to be 20°C. Peripheral empty cabin temperature: calculated at 35°C, considering the heat transfer of the empty cabin and deck, the heat transfer coefficient of the bulkhead is adjusted to 5w / m2K.

[0048] Features of propylene oxide for cargo hold loading:

[0049] Specific gravity: 0.859t / m3, loading rate: 0.98, specific heat: 1.95KJ / kg.℃.

[0050] The specific implementation plan of the system:

[0051] Considering the influence of the sun's radiant heat, the horizontal deck is painted with dark paint, and the heat transfer coefficient of the remaining compartments is adjusted to 5w / m2K according to the heat transfer coefficient of the bulkhead.

[0052] The total heat load ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com