Device and method for measuring overall transmittance, reflectance and color of hollow glass

A reflectance and transmittance technology, applied in the field of optical detection, can solve the problems of inconsistency of finished products, influence of measurement results, easy oxidation of low-emissivity films, reduce size and thickness requirements, simplify preparation and measurement processes, and avoid inconsistent measurement results. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

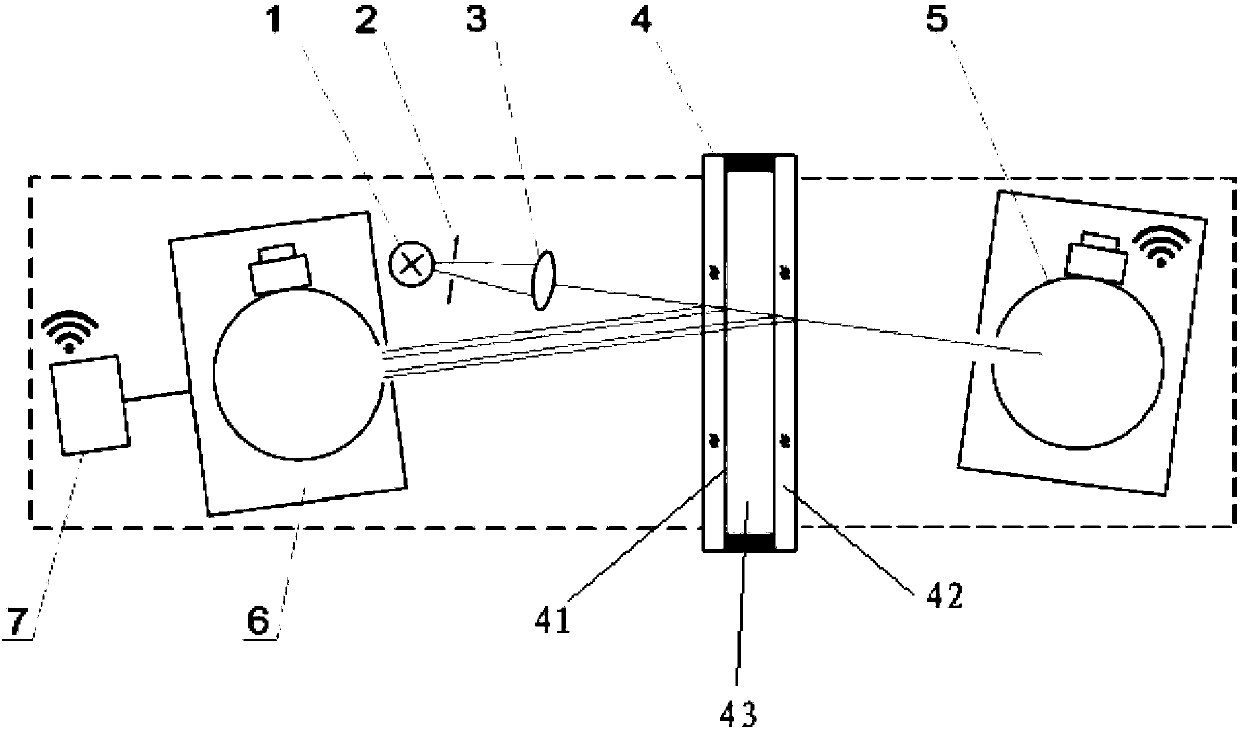

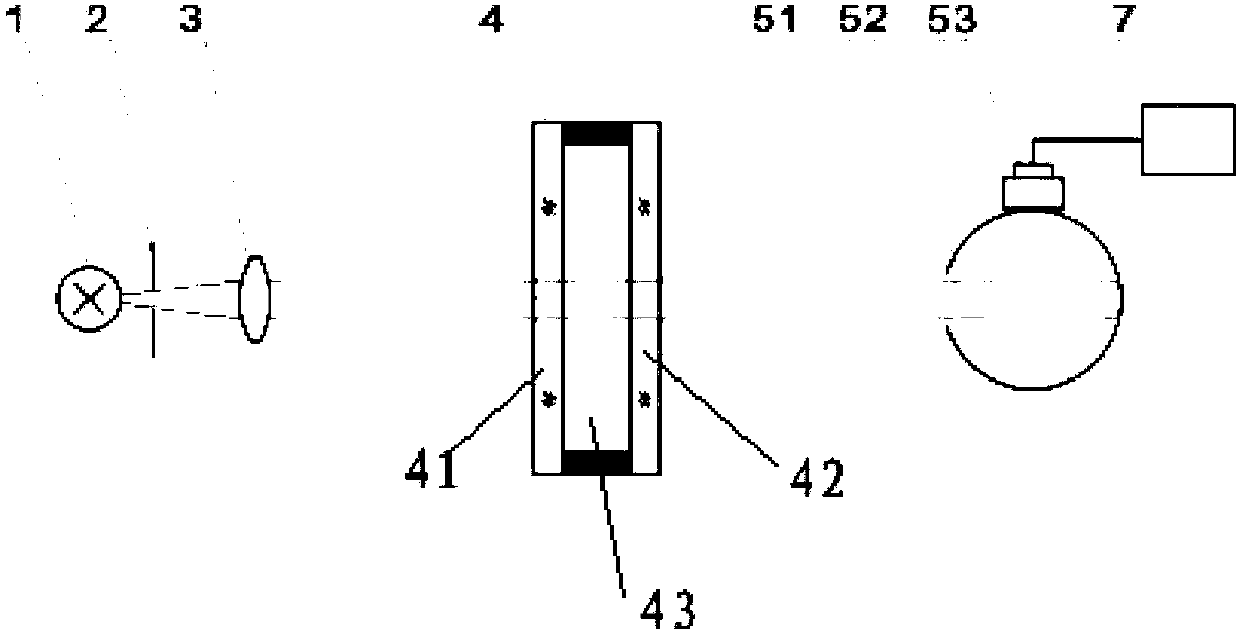

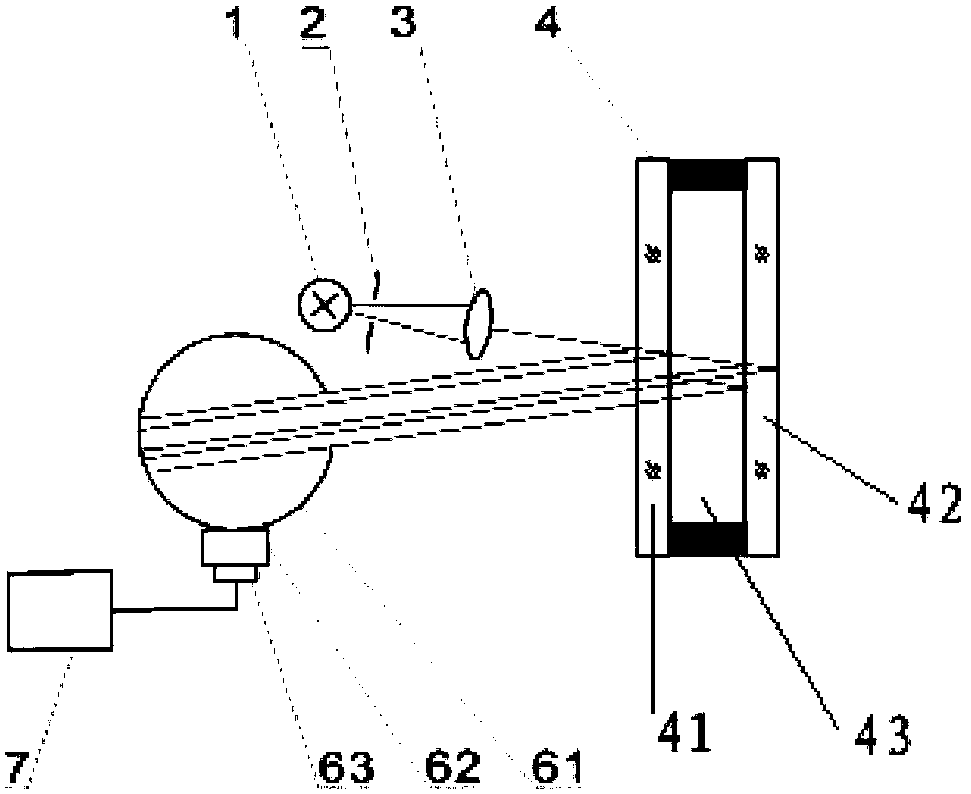

[0077] The present invention provides a device for measuring the overall transmittance and reflectance and color of hollow glass, the device includes a transmitting device, a transmission component 5, a reflection component 6 and a signal acquisition and processing unit 7, and the hollow glass 4 includes at least two pieces glass, and a cavity is formed between two adjacent pieces of glass, the transmission assembly 5 and the reflection assembly 6 are respectively located on both sides of the hollow glass 4, the reflection assembly 6 and the emission device are located on the hollow glass 4 on the same side. The emitting device is used for emitting light beams. The transmission component 5 is used for receiving the light beam transmitted by the light beam after passing through the insulating glass 4, and converting the light signal of the light beam into an electrical signal. The reflection assembly 6 is used to receive the light beam reflected by each piece of glass after th...

Embodiment 2

[0094] The present invention also provides a method for measuring the overall transmittance, reflectance and color of hollow glass by using the above-mentioned device, please refer to Figure 5 , which is a flow chart for measuring the overall transmittance, reflectance and color of hollow glass in the present invention, such as Figure 5 As shown, the method includes the following steps:

[0095] The overall transmittance of the insulating glass is measured according to the transmitted light path; wherein, the insulating glass includes at least two pieces of glass, and a cavity is formed between two adjacent pieces of glass;

[0096] The reflectance of each piece of glass of the insulating glass is measured according to the reflected light path, wherein the reflectance of each piece of glass is the reflectance of the light source surface and the light source reverse surface;

[0097] Obtain the overall reflectance of the insulating glass according to the reflectance of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com